Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Overview of Plastic Rods - Plastic Rods (Plastic Rods and Rods) are extruded or molded from over 500 different plastic materials for a wide variety of uses. Most of the plastic rods sold by HONY Plastics are used in the CNC manufacturing of bearings, rollers, gears, seals, and other precision plastic parts.

Plastic Rods are produced from: Acetal / Delrin® Rods, Nylon® Rods, teflon® PTFE Rods, PEEK Rods, vespel® Rods, Torlon® Rods, PVC Rods and hundreds of other materials. Plastic Rods from HONY Plastics comply with Federal Supply Class (FSC): 9330 - Plastic Manufacturing Materials - Plastic Rods

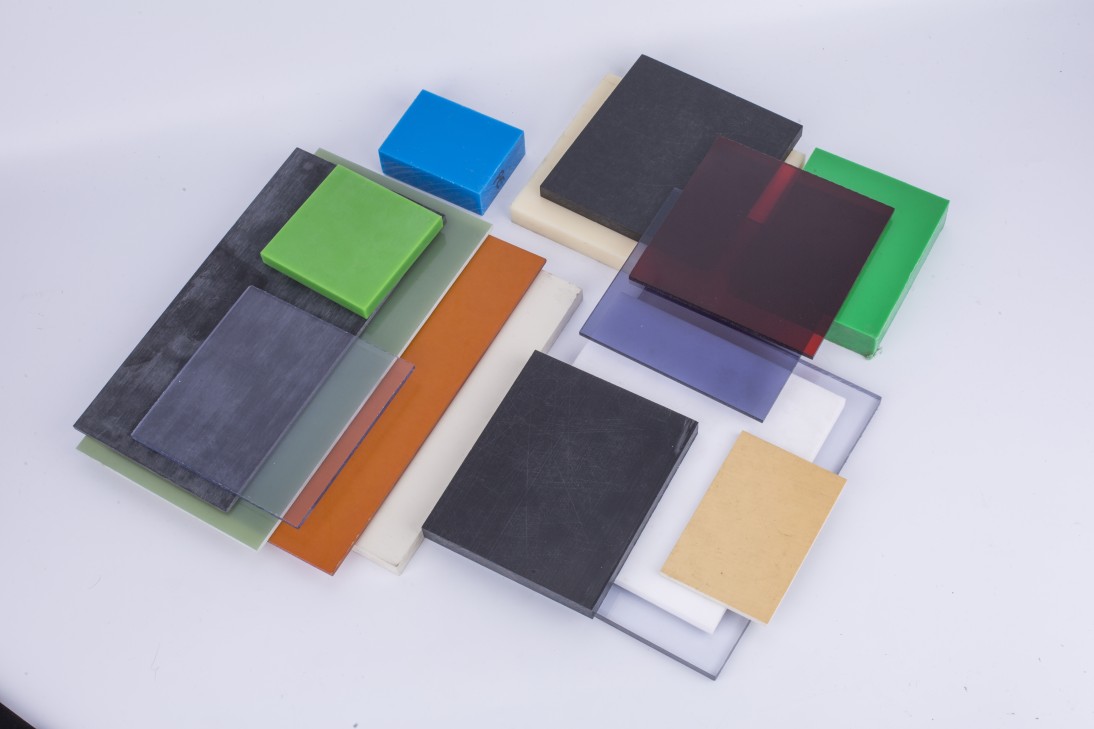

Plastic sheets include any flat, continuous piece of plastic material that is relatively stiff. These materials can be thin, but are generally more substantial than plastic film, which can be rolled and manipulated without any specialized equipment.

If you work with plastics regularly, you`re likely quite familiar with the basic qualities of plastic sheets. However, many industry professionals are so comfortable with the specific materials they already use, that they may not dedicate much thought to what goes into producing plastic sheets or all the different material options available for different purposes or use cases.

Whether you`re just getting involved with the powerful world of plastics or are already very familiar with the qualities of specific plastic sheets, here`s a guide to the elements you may not have considered.

There are a huge array of plastic materials available today. So the specific processes and polymers used may vary slightly. However, the basics are fairly consistent across many popular plastic sheet products.

Thermoplastics include popular materials like acrylic and polycarbonate, which can be easily molded or melted when heated to a specific degree, though the melting point of each polymer varies. These thermoplastics often start as liquid polymers that are squeezed through a tiny slit for casting. This process is often completed in bulk with multiple cooling rows filled at one time. Once the molds cool down, the plastic is solid and can be removed from the rows, leaving stiff sheets of the same size and material. This process can be completed for plastic sheets of various gauges and dimensions. These stock sizes can also be cut, shaped, and machined once they`re produced.

Plastic sheets can be used for a huge array of applications, especially once they`re cut to size, routed, and machined to suit the needs of specific industries. Though the specific applications are nearly endless, here are some of top industries that use these materials regularly:

Every type of plastic offers its own set of benefits for specific industries and applications. For example, polycarbonate provides extreme impact resistance, while hdpe offers very low water absorption. So there are advantages of specific products that go above and beyond the qualities listed here, but these are some of the most prominent reasons why people choose to work with plastic sheets in general.

Since there are so many types of plastic sheets available, it is an incredibly versatile material that`s well-suited for numerous applications. Basic sheets can even be cut to size, produced in various colors and finishes, and thermoformed into various shapes. So it`s much easier to customize plastics to the needs of each project than it is to manipulate other strong materials like metal and wood.

Most plastics are also incredibly durable, with different benefits for different types of plastics. Some provide chemical resistance, while others are well suited for standing up against friction.

When compared to other strong materials like metal and glass, plastics are very lightweight. This makes them easy to handle and transport. It also makes them attractive for automotive and aerospace applications where keeping weight down can make high-powered systems more efficient.

Since plastic sheets can be produced and customized at scale, it also tends to be a fairly cost-effective material. This varies depending on the type of plastic and what value-added services are needed, but it does tend to be an affordable alternative to other options like metal.

The plastic sheets market is currently very strong. It`s grown significantly over the past several years and is expected to continue on that trajectory. The benefits listed above, along with the efficient processes and customization options available have contributed to this growth across an array of different industries served.

The pandemic also made a major impact on the demand for plastic sheets. These materials were often used as sneeze guards, face shields, and protective barriers in medical facilities and essential businesses. As organizations begin adjusting to their new normal, many of these safety features are likely to remain, and facilities are continuing to find new ways to make their spaces safer for everyone.

HONY plastic is a large wide supplier of plastic, sheet, rods, tubing, tube , film, plastics, UHMW, and plexiglass.

You can place orders Plastic Sheet, Plastic Rod, Plastic Tubing, Bar, Tube and Plastic Film from HONY Plastic. Plastic distributor materials; UHMW, PVC, Plexiglass, Acrylic, Delrin, Nylon, PTFE. We are an Industrial Supply and offer fabrication of plastic sheets, plastic rods and plastic tubing.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.