Wind and Solar

Wind power

The use of wind energy dates back about two thousand years, when very simple wind power installations evolved over the next few centuries into the first horizontal-axis wind turbines.

However, at the end of the 18th century, another form of energy was harnessed that changed our lives forever - electricity. Therefore, windmills were redesigned as wind generators, the mechanism by which wind energy is converted into electricity.

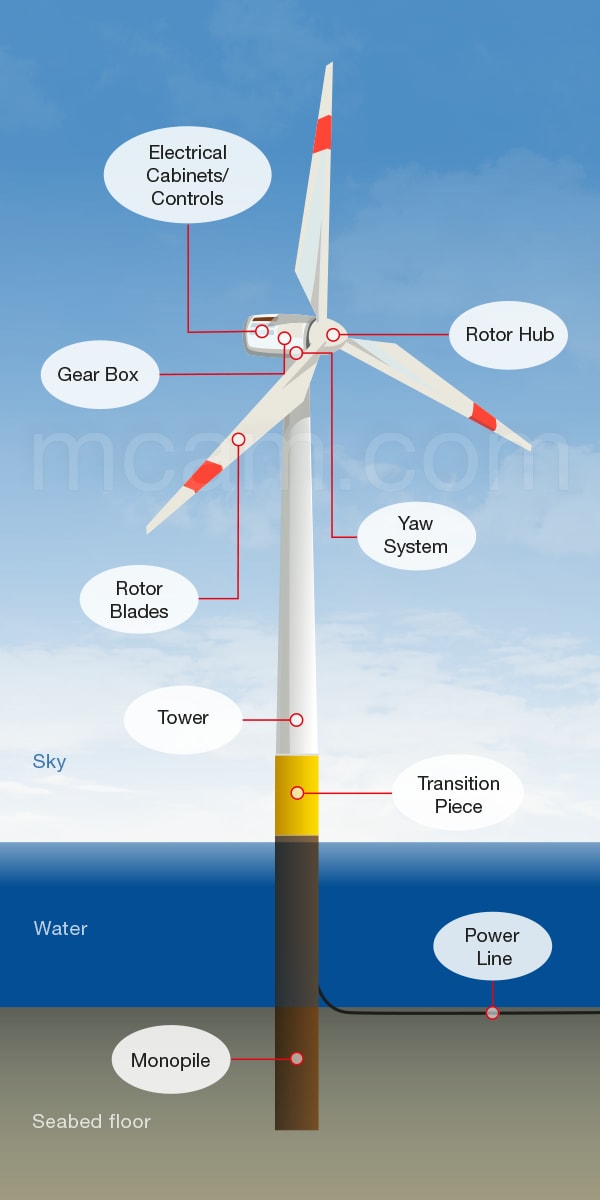

Fast forward to the 21st century, and modern wind turbines consist of three basic elements:

Base and Tower - for positioning and supporting the wind turbine

Nacelle - houses the yaw system, drive train and electrical cabinet

Rotor - contains rotor hub and blades

Key considerations for onshore wind vs. offshore wind

• Pedestal technology

Onshore wind farm foundations rely on concrete conical bases, anchored into the ground by multiple piles. Offshore wind power foundations use fixed bottom foundations, such as monopile systems for water depths up to 30 meters and jackets for 50 meters. Above this depth, a floating base is used, which allows great flexibility in positioning the fan.

• Installation technology

Onshore construction sites can use standard lifting equipment, and delivery cables can be routed to users. Offshore installation projects are costly due to offshore weather conditions and the need for long cables, offshore cranes, and specialized vessels.

• Fan capacity

Onshore wind turbines are typically limited to 5 MW, while offshore wind turbines are capable of rated power of 14 MW. Because cost is not linear with rated power, large wind turbines typically generate electricity at a lower cost.

• capacity factor

Offshore wind turbines have higher capacity factors. An example of using this factor – actual generation versus theoretical maximum – is the EU capacity factor for 2019, with 24% for onshore wind and 38% for offshore wind.

Product advantages

Improve productivity

Reduced mean time to repair through the use of maintenance-free self-lubricating materials

Products with high dimensional stability provide automation possibilities

Increased product life due to higher chemical resistance of components

Low-friction engineering plastics save material costs

Friction-optimized products reduce noise and eliminate stick-slip

Realize solutions through a wide range of products to save costs and ensure safety in use

Products and Applications

Solar Energy

Product

Application

Duratron®PBI

Wafer Holders and Combs for Photovoltaic Solar Cell Operating Systems

Ertalyte®TX

Clips, thimbles and suction filter elements for thin-film solar panel handling systems for high temperature environments

Fluorosint®HPV,Fluorosint®500

Liners, spray device elements, sprockets and guides for wet chemical equipment

Ketron®PEEK,Ketron®PEEK 1000

Bushings, rollers and clamps on trackers for concentrating solar power including CSP

Techtron®HPV PPS

Wind Energy

Product

Application

Ertalyte®TX

Slip rings in yaw bearings

Ketron®PEEK

Wear discs and friction pads for wind turbine brakes

Nylatron®LFX , Nylatron®NSM

Sealing ring for power transmission

Nylatron®703 XL

Bearing cages for large ball bearings

TIVAR®ECH 7000 , TIVAR®CeramP

Bearing elements and spacers

Case study

A manager of a "wind farm" had contacted Mitsubishi Chemical Advanced Materials for assistance troubleshooting performance and maintenance issues. Due to weather, temperature and mechanical loads, the bearing surfaces of the positioning systems of each unit quickly failed, which also resulted in extreme noise. These failures could force maintenance crews to climb up 80-meter ladders to lubricate the unit's stuck bearings, whether it's night, freezing cold or scorching heat. Loss of capacity and emergency maintenance costs due to unit damage is a major expense.

Solution

Ketron® PEEK HPV products from Mitsubishi Chemical Advanced Materials are the designated solution. It offers an ideal combination of lubricity, load carrying capacity, low coefficient of friction and noise rejection.

In individual cases, Ertalyte® TX or Nylatron® 703 XL can also be used.