Torlon® polyamide-imide (PAI) 4203

Get Latest Price| Payment Type: | Paypal,T/T |

| Incoterm: | FOB,CIF,EXW,DDU,DDP |

| Min. Order: | 1 Kilogram |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,HONGKONG,GUANGZHOU |

| Payment Type: | Paypal,T/T |

| Incoterm: | FOB,CIF,EXW,DDU,DDP |

| Min. Order: | 1 Kilogram |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,HONGKONG,GUANGZHOU |

Model No.: Torlon

Brand: Torlon

| Selling Units | : | Kilogram |

| Package Type | : | Export package |

The file is encrypted. Please fill in the following information to continue accessing it

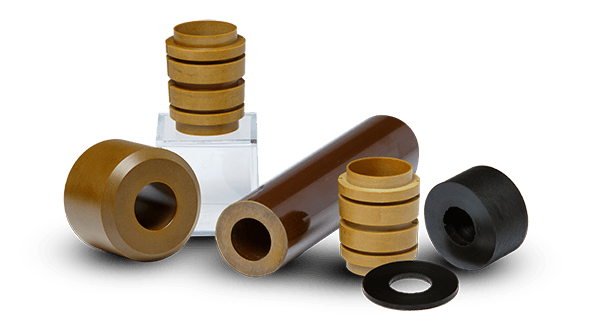

Torlon board, Torlon rod, TI-5013 board, TI-5013 rod, PAI board, PAI rod, Torlon4203 board, Torlon4203 rod

PAI: English name Polyamideimide, is a new type of engineering plastics containing amide groups. Due to the very stable aromatic heterocyclic structure in the polyimide molecule, it exhibits heat resistance and low temperature resistance unmatched by other polymer materials, and has excellent mechanical properties and dimensional stability in high temperature environments .

●IC test fixtures ●High-temperature heat insulation components for semiconductor and liquid crystal manufacturing ●High-speed bearings

Main performance:

●Under the atmospheric environment, it can withstand the working temperature [can be used continuously at 250°C]

●Excellent mechanical strength, rigidity and creep properties can be maintained under a wide range of temperature conditions

●Excellent dimensional stability in the temperature range of 250℃

●Excellent wear resistance and friction properties [especially PAI4203 and PAI5530]

●Excellent UV resistance

●Excellent resistance to high-energy radiation [gamma rays and X-rays]

●Inherent low combustion performance

Product Category:

● (Torlon 4203)TI-5013[Extrusion Grade] [PAI; Tan]

Torlon4203 has high toughness and impact strength among all PAI grades. This extrusion grade of PAI is used extensively in precision parts for high-tech equipment. In addition, good electrical insulation makes it widely used in the field of electrical components.

● (Torlon 4301)TI-5031[extrusion grade] [PAI + graphite + PTFE; black]

The addition of PTFE and graphite makes it more wear resistant, has a lower coefficient of friction and is less prone to stick-slip than unfilled grades. It also has excellent dimensional stability over a wide temperature range. This extruded PAI provides superior performance in high wear applications such as non-lubricated bearings, seals, bearing cages and reciprocating compressor parts.

● (Torlon 5530)TI-5023[Molded Grade][PAI+GF30; Black]

Filled with 30% glass fiber reinforced grade has higher rigidity, strength and creep properties than pure material grade. Ideal as a structural material for long-term support of loads at elevated temperatures. In addition, Torlon 5530 exhibits excellent dimensional stability up to 250°C, so it is very suitable for precision components in the electronics industry and semiconductor industry.

When Torlon 5530 is used as a sliding part, it should be noted that its glass fiber is easy to scratch the mating surface, so it needs to be carefully considered.

●Torlon sheet, Torlon bar, TI-5013 sheet, TI-5013 bar, PAI sheet, PAI bar

Application fields:

Few materials live up to Torlon's high standards. It outperforms most other materials (even some metals) and is one of the most resilient thermoplastics. With its versatility, it offers strength, insulation and toughness, providing solutions for numerous industries. Below are some major applications of Torlon.

1. Bearing

If you're interested in cost-effective and innovative design solutions, you might want to try Torlon bearings.

Corrosion is one of the worst enemies of bearings. PAI bearings can work in harsh environments opposite to ordinary bearings. Including areas such as swimming pools and sea water.

As a plastic, PAI is significantly lighter than metal. This plastic bearing requires minimal energy and weight to move compared to steel bearings.

More suitable for design engineers is the flexibility that PAI provides. Custom designs can be easily fabricated using this material, giving engineers the flexibility to design bearings around equipment.

Metal bearings require heavy lubrication. This is a countermeasure against heat, corrosion and friction. First, this material is non-corrosive. Second, there's no metal-to-metal contact issues, so you can forget about heat dissipation.

Other reasons why this material is suitable for bearings include:

Noise control

High level of hygiene

Shock load absorption

low inertia

2. Gears and sprockets

Similar to bearings, gears made of PAI are self-lubricating, lightweight, and run quietly. Polymer gears have been around for years, but PAI is relatively new. Using it in gears produces a component that not only operates at extremely high temperatures, but also possesses unparalleled strength.

Gears are subject to constant wear and friction conditions, which is one good reason why Torlon PAI gears are so popular.

3. Aerospace applications

The application of this material in the aerospace industry has made PAI popular. Materials in this industry need to meet very high standards. Some of them are:

· Ease of manufacture

· Lightweight

· Wear-resistant

· Friction

· Anti-corrosion

· Resistant to extreme temperatures

· Resistant to low temperature

This material has long been the answer to these challenges. There are some examples where the material offers unrivaled solutions in the industry.

Fastening Screws: Global Aviation Group needed screws that not only meet load-bearing requirements, but also reduce production requirements. Interference with radar equipment signals is also a problem to be avoided. Since metal screws did not meet these requirements, the company chose Torlon 4203 screws.

Thermal Isolator: The Boeing 787 requires hydraulic lines to run through its fuel tanks. The insulation of these lines must be able to handle the intense heat energy. The natural choice for this application is Torlon 4203 PAI.

Air and Fuel Connections: The stainless steel connections in the F-16 did not fit due to lightning strikes. Torlon 4203 solves this problem as it can withstand constant vibration and temperatures up to 400 degrees.

These examples illustrate why Torlon PAI is considered one of the toughest melt processable materials.

4. Industrial parts

This highly reliable thermoplastic is often recommended for precision components, from engine parts used in Formula 1 racing to precision parts in space craft and many other uses, the material is suitable for a wide variety of challenging industrial requirements. Its wear and heat resistance and incredible strength make it ideal for extreme conditions.

5. Oil and Gas Applications

The oil and gas industry is also very demanding. Torlon PAI is a reliable material because it can handle extreme heat and pressure. This makes it the material of choice for connector bodies, compressor valves, seals and other components.

Other applications of this material are:

Compressor blades

Slide parts

Bushing

Transmission

cam

Thrust washer

High temperature electrical connector

Duratron T4203 PAI and Duratron T5030 PAI offer excellent electrical characteristics and high temperature stability. (Replaces previous materials: Nylon, Mitsubishi Chemical Advanced Materials PPS, Duratron® PEI)

Bearing cage

The extremely low expansion rate and excellent wear resistance of Duratron T4203 and T4301 PAI make the running speed of the bearing and the life of the parts improved and extended. (replaces previous materials: steel cap, hardened steel ball, bronze bushing)

tank core

The excellent compressive strength and wear resistance of Duratron T4203 PAI enable aluminum cans to have higher production rates in the molding process, and extend the life of parts, etc. (replaces previous materials: Nylon, PE-UHMW, ceramic-coated steel)

Bearing cage

The extremely low expansion rate and excellent wear resistance of Duratron T4203 and T4301 PAI make the running speed of the bearing and the life of the parts improved and extended. (replaces previous materials: steel cap, hardened steel ball, bronze bushing)

Chip Nests and Sockets

Components processed by Duratron T5530 PAI maintain dimensional stability over a wide temperature range, increasing and extending reliability of test joints and component life. (replaces previous material: Duratron® PI)

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.