Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

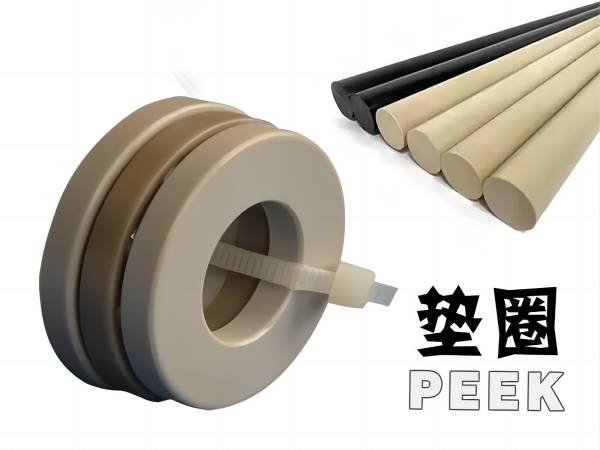

PEEK gaskets at high temperatures and pressures are a high performance alternative to plastics that are resistant to high temperatures and chemicals.

PEEK gaskets, chemically known as polyether ether ketone, offer a unique combination of properties for numerous extreme applications. As a semi-crystalline thermoplastic and high-purity polymer, PEEK exhibits excellent mechanical strength and chemical resistance at elevated temperatures. It is a high-strength alternative to PTFE fluoropolymers.

The main advantages of PEEK washers:

1. excellent resistance to thermal degradation and good chemical stability even at high temperatures.

2. excellent chemical resistance to a wide range of oils, alcohols, solvents and organics, as well as strong acids and bases, even at low concentrations and temperatures.

3. Hydrolysis resistance allows PEEK to maintain all physical properties with very low moisture absorption when continuously exposed to water or steam at high temperatures and pressures.

4. Excellent creep resistance allows PEEK gaskets to withstand high stresses over a long service life.

5. able to withstand frequent sterilization processes, with excellent resistance to sterilization.

6. V-0 flammability rating, low smoke and toxic gas emissions when exposed to flame, high safety performance.

7. Good abrasion and wear resistance to friction and abrasive environments.

8. Maintains electrical properties over a wide range of frequencies and temperatures, making it suitable for electronic and electrical applications.

9. radiation resistance allows PEEK to be used in or repeatedly sterilized by high doses of ionizing radiation with a high degree of chemical stability.

Depending on application requirements, PEEK washers can be reinforced with glass or carbon fibers to improve strength and stiffness characteristics. Reinforced PEEK washers offer increased mechanical stability, especially in applications where temperatures exceed 350°F (175°C).

Application Areas for PEEK Gaskets

Considered by the medical community as an advanced biomaterial for use in medical implants and compatible with high-resolution magnetic resonance imaging (MRI), PEEK gaskets show promise for a wide range of applications in the biomedical field.

At the same time, PEEK is one of the few plastics that is compatible with ultra-high vacuum (UHV), which is necessary for many analytical techniques and particle gas pedals, demonstrating its importance in high-tech research. Chemical processing and pharmaceutical applications rely on PEEK's chemical resistance, high purity and ability to withstand sterilization processes, justifying its widespread use in the chemical and pharmaceutical industries.

In addition, PEEK gaskets are used in many electronic products from cell phones to circuit boards for their lightweight strength and reduced noise, vibration, and acoustic vibration harshness (NVH), demonstrating the wide range of possible applications in electronics.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.