Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

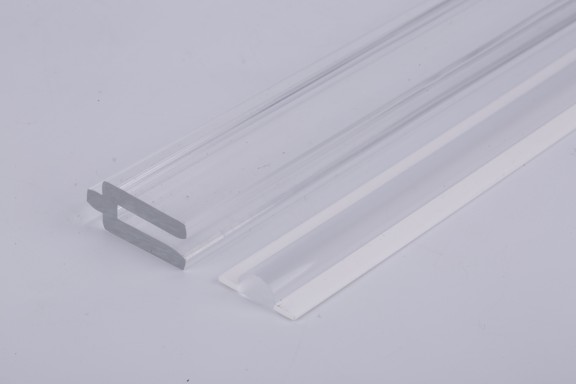

PMMA (polymethylmethacrylate, commonly known as acrylic)

Chemical and physical properties:

PMMA has excellent chemical properties and climate change resistance. The penetration of white light is as high as 92%. PMMA products have very low birefringence and are particularly suitable for making DVDs, etc. PMMA has room temperature creep properties. As the load increases and time increases, stress cracking may occur. PMMA has good impact resistance properties.

High dimensional stability, good heat resistance, cold resistance, good insulation, high surface resistance, relatively brittle, high surface hardness (comparable to aluminum) due to notch sensitivity, high processing requirements, and very sensitive to moisture and temperature , tough but not broken, light and not easily deformed, resistant to oxidizing acids, inorganic salts, plant liquids, oils, fats and weak alkali; not resistant to strong sulfuric acid, strong nitric acid, strong alkali, alcohols, ketones, fertilizer soluble in aroma Hydrocarbons and other organic solvents.

Low moisture, small molding shrinkage, high dimensional stability, poor thermal stability, high melt viscosity.

Pa6 polyamide 6 or nylon 6

High mechanical strength, good toughness, high tensile and compressive strength, strong ability to absorb impact, pressure and vibration, wear resistance, lubricity, fatigue resistance, non-toxic, easy to form.

Corrosion-resistant and excellent electrical chlorine performance.

It is easy to absorb water, has poor optical resistance, has a large molecular weight and can be cast into nylon. It has high strength and can be used to form complex molds or small parts.

Chemical and physical properties:

The chemical and physical properties of PA6 are very similar to Pa66, however it has a lower melting point and a wide process temperature range. Its impact resistance and dissolution resistance are better than PA66, but it is also more hygroscopic. Because many qualities of plastic parts are affected by hygroscopicity, this must be fully taken into consideration when designing products using PA6. In order to improve the mechanical properties of PA6, various modifiers are often added. Glass is the most common additive, and sometimes synthetic rubber, such as EPDM and SBR, is added to improve impact resistance. For products without additives, the shrinkage rate of PA6 is between 1 and 1.5%. Adding glass fiber additives can reduce the shrinkage rate to 0.3% (but it is slightly higher in the direction perpendicular to the process). The shrinkage rate of molded assembly is mainly affected by the crystallinity and hygroscopicity of the material. The actual shrinkage rate is also a function of plastic part design, wall thickness and other process parameters.

PA66 polyamide 66 or nylon 66

PA66 has the highest mechanical strength among plastics and is the most widely used variety. It has strong crystallinity and high hard and thermal properties. It has a higher yield strength than PA6 and PA610, and a water absorption rate of 0.07. It is wear-resistant and has high tensile strength after stretch orientation treatment.

Insoluble in weak bases, alcohols, esters, ketones and gasoline; soluble in phenol, concentrated sulfuric acid and low molecular organic acids, with a melting point lower than PA1010; low viscosity and good fluidity.

Chemical and physical properties: PA66 has the highest melting point among polyamide materials. It is a semi-crystalline-crystalline material. PA66 can maintain strong strength and stiffness at higher temperatures. PA66 remains hygroscopic after molding, the extent of which depends primarily on the material's composition, wall thickness, and environmental conditions. When designing products, the impact of hygroscopicity on geometric stability must be considered. In order to improve the mechanical properties of PA66, various modifiers are often added. Glass is the most common additive, and sometimes synthetic rubber, such as EPDM and SBR, is added to improve impact resistance. PA66 has a lower viscosity, so it flows very well (but not as well as PA6). This property can be used to process very thin components. Its viscosity is sensitive to temperature changes. The shrinkage rate of PA66 is between 1 and 2%. Adding glass fiber additives can reduce the shrinkage rate to 0.2 to 1%. The difference in shrinkage rate in the process direction and the direction perpendicular to the process direction is large. PA66 is resistant to many solvents, but is less resistant to acids and some other chlorinating agents.

PA12 polyamide 12 or nylon 12

Chemical and Physical Properties: PA12 is a linear, semi-crystalline-crystalline thermoplastic material derived from butadiene. Its properties are similar to PA11, but its crystal structure is different. PA12 is an excellent electrical insulator and like other polyamides it is not susceptible to moisture and has modified varieties with enhanced properties. Compared with PA6 and PA66, these materials have lower melting points and densities, and have very high moisture regain. PA12 has no resistance to strong oxidizing acids. The viscosity of PA12 mainly depends on humidity, temperature and storage time. Its fluidity is very good, and its shrinkage rate is between 0.5 and 2%, which mainly depends on the material type, wall thickness and other process conditions.

PBT polybutylene terephthalate

Chemical and physical properties: PBT is one of the toughest engineering thermoplastic materials. It is a semi-crystalline material with very good chemical stability, mechanical strength, electrical insulation properties and thermal stability. These materials have good stability over a wide range of environmental conditions. The tensile strength of PBT is 170Mpa. Too many glass additives will cause the material to become brittle. PBT: Crystallizes very quickly, which will lead to bending deformation due to uneven cooling. For plexiglass additive type materials, the shrinkage in the process direction can be reduced, but the shrinkage in the direction perpendicular to the process is basically no different from ordinary materials. Generally, the shrinkage rate of materials is between 1.5~2.8%. The shrinkage rate of materials containing 30% glass additives is between 0.3% and 1.6%. The melting point (225 degrees) and high-temperature deformation temperature are lower than PET materials. The softening temperature for the card is approximately 170 degrees. The glass transition temperature (glass transition temperature) is between 22 degrees and 43 degrees. Because PBT has a high crystallization speed, its viscosity is very low, and the cycle time for plastic parts processing is generally low.

PC+ABS material

Advantages:

1. Increased ABS heat resistance and dimensional stability, improved PC low temperature, improved rear wall impact resistance, and reduced costs

2. Physical equilibrium 3. Good formability 4. Excellent impact strength 5. Good humanity at low temperatures 6. Good heat resistance

Molding performance: 1. The material cost is close to ABS, but its physical properties are higher than ABS 2. This material provides high distortion temperature, high temperature and high strength3. Its processing performance is similar to ABS, but unlike PC, which is more difficult to process than ABS 4. Increase ABS heat-resistant dimensional stability, improve PC low temperature, rear wall impact resistance, and reduce costs 5. The material has a certain degree of hygroscopicity, and defects such as spots, moire, and blistering will occur on the product during molding. Therefore, drying should be carried out before molding.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.