Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

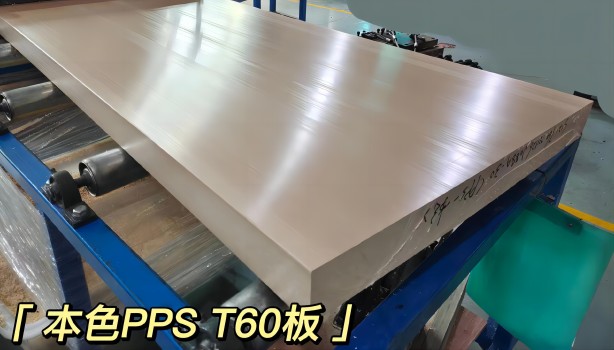

Development of PPS sheet and Bar

PPS (Polyphenylene Sulfide), also known as polyphenylene sulfide, is a thermoplastic resin with a benzene sulfide group in the main chain of the molecule, is a crystalline (55%-65% crystallinity), highly rigid white powder polymer. HONY Plastic can provide sheets with specifications ranging from 5 to 80 mm × 620 mm × 1000 mm and rods with specifications ranging from 6 to 100 mm × 1000 mm.

PPS sheet and bar has superior chemical resistance and hydrolysis resistance, excellent friction resistance, very good dimensional stability, excellent resistance to high energy radiation, good UV resistance and flame retardancy, excellent electrical insulation. When the use of POM, PET, PEI and PSU have defects, and the use of PI , PEEK and PAI and the cost is too high must be replaced by more economical materials, you can choose PPS to replace. At present, PPS sheet and bar is mainly used in the automotive industry, electrical insulation, electronics industry, machinery and equipment manufacturing and other fields.

PPS sheet and bar and its raw materials are relatively high technical barriers, Europe and the United States and Japan started early, the U.S. Phillips Company in 1971 to successfully achieve industrial production of PPS. 2017, the global production of PPS sheet and bar more than 300 tons, the growth rate remained at about 8%, the main PPS sheet and bar manufacturers are Japan Toray, Dai Nippon Ink Chemical DIC, Germany Lausch Lead, Germany Enzinger, etc.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.