Application Fields

UHMWPE has been widely used in textile, paper, packaging, transportation, machinery, chemical, mining, petroleum, agriculture, construction, electrical, food, medical, sports and other fields, and began to enter the field of conventional weapons, ships, automobiles and so on.

Specific applications include:

1.Wear-resistant and impact-resistant applications: textile machinery: such as bobbin thrower, shuttle bar, gears, couplings, flower sweeping rod, buffer blocks, eccentric wheels, rod bushings, oscillating rear beam and other impact-resistant wear parts. Paper machinery: such as paper machine scraper, suction box cover, deflector, water wings, pressure sealing parts, joints, sealing shaft, deflector, scraper, filter, etc.. Packaging machinery: instead of modified fluoroplastics to make guide rails, conveyor slider seat, fixed plate, etc.. General machinery: making gears, cams, impellers, rollers, pulleys, bearings, axle tiles, bushings, pins,

gaskets, gaskets, elastic couplings, screws, pipe cards, etc., as well as wharves, bridge piers, protective plates.

UPE gears and other drive applications

2.Self-lubricating and non-adhesive-based applications: material storage and transportation: making powdery class lining, such as silos, hoppers, chutes and other reflux devices, sliding surfaces, rollers, etc., as well as coal hoppers, powder product hoppers and other hoppers such as hopper lining storage bin hopper liner. Agricultural and construction machinery: making anti-wear plates and brackets for agricultural tools. Sporting goods: making skateboards for ice skating, sled towing boards, etc.

UPE wear parts

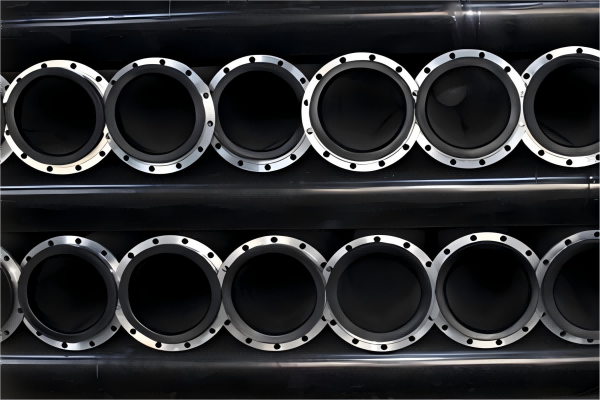

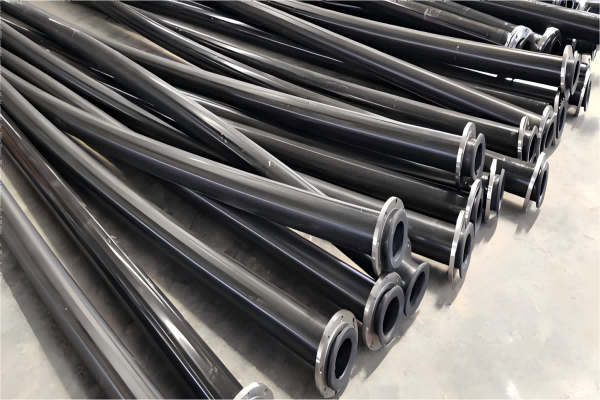

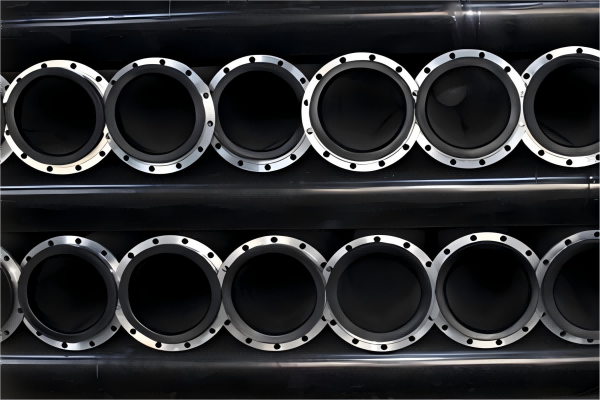

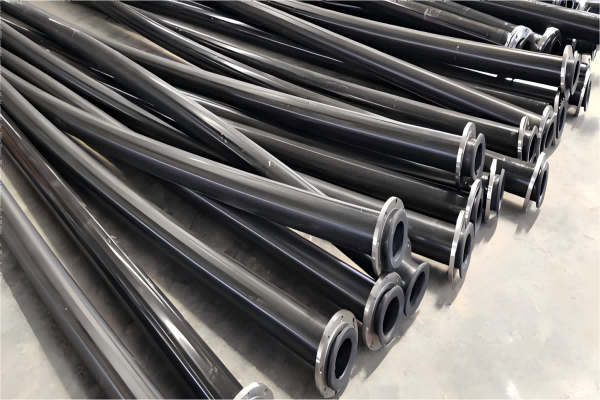

3.Corrosion-resistant and non-absorbent applications: Container packaging: making warm water containers for solar energy equipment. Chemical equipment: to make chemical industry parts, such as sealing filler plate, filler material, vacuum mold box, pump parts, bearing lining tile, gear, sealing bond. Conveying pipes.

UPE boards, molded boxes

4.Hygienic and non-toxic applications: food and beverage industry: manufacture of various gears, cams, conveyor line wear-resistant guardrails, gaskets, guide rails, and a variety of friction-reducing, self-lubricating bushings, linings, etc., such as guard rails, star wheels, guided kun gears, bearing linings and so on for food machinery.

UPE high strength sand slurry pipe

Who are the manufacturers of UHMWPE?

International Manufacturers

Honeywell: Honeywell is one of the world's leading manufacturers of UHMWPE fibers, and its Spectra brand is well known in the field of high-performance fibers.

DSM: DSM is a Dutch company with Dyneema as its brand name for high-performance UHMWPE fibers, which are widely used in areas such as bulletproof vests, ropes and composites.

Celanese: One of the world's largest and most complete UHMWPE manufacturers.

Quadrant: "Quadrant AG": formerly headquartered in Zurich, Switzerland, acquired by Mitsubishi in 2019 and renamed Mitsubishi Chemical Advanced Materials AG on April 1 of the same year.

KPIC: a major UHMWPE producer in South Korea.

Asahi Kasei: a Japanese company that produces UHMWPE products for the food processing and handling, power, railcar, steel, cement, food, chemical, battery, minerals and metals industries.

Mitsui Chemicals: A Japanese chemical company with UHMWPE products supplied in the Asia Pacific region.

Chevron Phillips Chemical: an international chemical company involved in the production of UHMWPE.

Thailand Petrochemicals (IRPC): produces POLIMAXX UHMWPE in a variety of grades.

LyondellBasell: the world's largest producer of polyolefins with LUPOLEN UHMWPE materials.

Murtfeldt: German manufacturer of high-performance engineering plastics.