Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

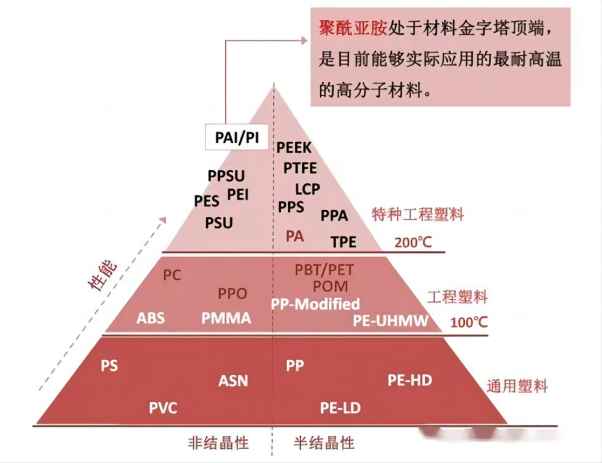

What is PI Polyimide material ?

PI is currently one of the best varieties of engineering plastics in heat resistance, some varieties can withstand long-term 290 ℃ high temperature for a short period of time to withstand a high temperature of 490 ℃, also resistant to very low temperatures, such as in the -269 ℃ liquid helium will not be brittle.

Types of PIs that HONY plastic can provide

30% Carbon Fiber (30 CF) Thermoplastic Polyimide (PI)

30% Glass Fiber (30 GF) Thermoplastic Polyimide (PI)

Unfilled Thermoplastic Polyimide (PI)

What is PAI Polyamideimide material ?

PAI is the highest performance, meltable plastic. It has outstanding resistance to high and low temperatures. Components machined from TORLON profiles have higher compressive and impact strength.

Types of PIs that HONY plastic can provide

30% Carbon Fiber (30 CF) PAI

30% Glass Fiber (30 GF) PAI

Low friction PAI

Unfilled PAI

PAI and PI are two Extreme & Imidized Plastic with excellent performance, which one is better?

1.Difference in heat resistance

Sub-thermoset and thermoplastic, thermoset PI will be higher than PAI, PAI long-term recommended temperature is 260 ° C, PI is 288 ° C, but PI in more than 300 ° C can still be used, because it does not have a melting point. Thermoplasticity is comparable to both.

2, Mstrength differences

Although PAI has the highest mechanical strength in the reinforced plastics, with excellent wear resistance to damage, but here in the PI will still be slightly better, PI toughness, compressive strength, bending strength, etc. will be better than PAI, after all, the PI is known as the "problem solving skills", and that "there is no polyimide will not be microelectronics technology today".

3, There are differences in mobility

PAI, PI have super high mobility, but PAI disadvantage is not easy to mold.

Because of these two excellent special engineering plastics, so that "plastic instead of steel", "plastic instead of wood" can continue to promote the material will benefit greatly.

About HONYPlastic polyamide (PA) engineering plastic Products

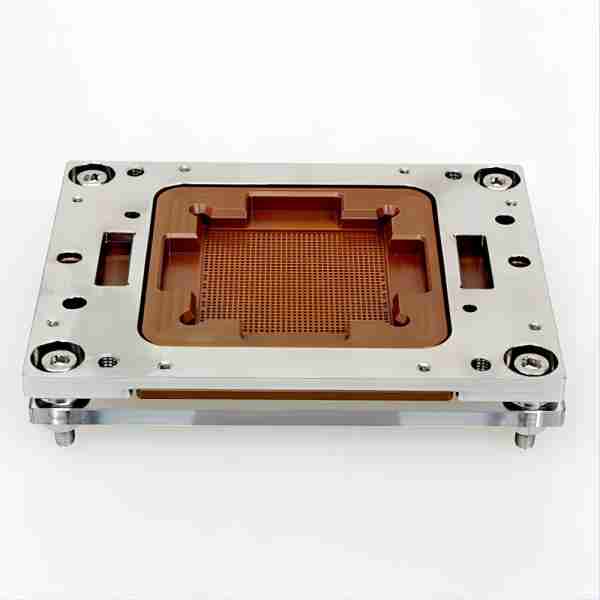

We machine PI ans PAI semi-finished products that are manufactured internally in our production facility. In addition, we can also machine your externally sourced PI and PAI materials on request. For this purpose, please contact us via sales@honyplastic.com

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.