Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

What is the material abbreviation for PEI?

PEI is a thermoplastic Polyimide with lower cost and larger production volume compared to other aromatic polyimides. From the comprehensive performance and performance/price ratio, polyetherimide is the most successful class of products in the research of modification of aromatic polyimides. Today we are from the preparation method, development history, performance characteristics and applications to understand the material PEI.

1. the introduction of PEI

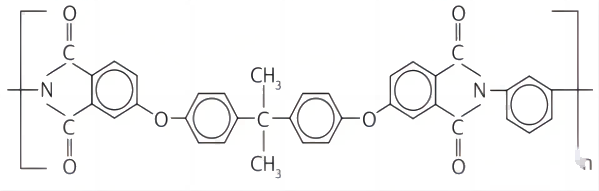

Polyetherimide is a transparent amber-colored amorphous thermoplastic special engineering plastics, English name: Polyetherimide, referred to as PEI. its molecular structure is as follows:

PEI molecular structure formula

1.1 PEI preparation

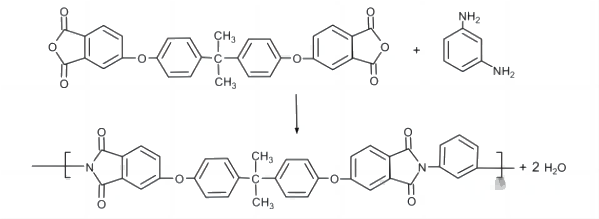

PEI is a high-performance amorphous polymer made from 4,4'-diaminodiphenyl ether or m-(or p-)benzene diamine and 2,2'-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride in dimethylacetamide solvent by heating polycondensation, powdering and imidization.

PEI polymerization reaction equation

PEI polymerization methods are: solution polymerization, melt polycondensation method, etc., of which the solution polymerization method for the current industrial production methods, while the extruder continuous extrusion polymerization method has been developed by the Shanghai Research Institute of Synthetic Resins in a small device on the success, and pushed to industrial production.

PEI reaction extrusion process

2. History of PEI development

1972 - The earliest successful development by the U.S. company GE;

1982 - GE realized industrialized production of PEI, trade name: Ultem™;

Early 1980s - Shanghai Research Institute of Synthetic Resins on polyetherimide research and development, product brand: YS-30;

2007 - SABIC completes the acquisition of the GE Plastics division to produce ULTEM™ PEI resins;

2018 - SABIC builds a new PEI product line in Singapore, increasing capacity by 50%;

In April 2021, the construction of the 20,000 tons per year PEI production line of ULTEM New Materials started, and is expected to be put into production in August 2022, with the trade name: PARYLS® PEI.

At present, the PEI resin on the market is produced by SABIC, the specific capacity is unknown, and domestic PEI resin has not yet seen sales.

3. PEI performance

The molecular structure of PEI contains both aromatic amine functional groups and ether structure. The aromatic ring and imide ring give it rigid creep resistance and high temperature stability, while the ether bond gives it the supple performance required by thermoplastic molding. Each material has its own advantages and disadvantages.

3.1 Advantages of PEI:

Good thermal stability, glass transition temperature of 217 ℃, long-term use temperature up to 170 ℃;

Excellent dimensional stability, low and stable linear coefficient of thermal expansion over a wide range of temperatures, so the ambient temperature has little effect on the size, no deformation in the use of higher temperatures and with loads, low creep sensitivity;

Excellent mechanical strength and modulus;

Outstanding electrical properties, in a wide range of temperatures (-40 ° C ~ 150 ° C) and frequency range is still able to maintain a basic constant, with a stable dielectric constant and dielectric loss;

Excellent infrared transmittance and high refractive index;

Naturally flame retardant and very low smoke generation;

Excellent radiation resistance and chemical resistance;

Unique plating capabilities;

Good molding and processing performance, low melt viscosity and high fluidity, can be molded with traditional thermoplastic melt processing technology and equipment.

3.2 Disadvantages of PEI:

Contains BPA (bisphenol A), limiting its use in baby-related products;

Notched impact sensitivity;

General alkali resistance, especially under heated conditions.

The performance of PEI can also be further enhanced by modification, such as adding glass fibers, carbon fibers or other auxiliary fillers.

Application of PEI

PEI has excellent performance, in the communications, automotive, aerospace and medical industries have a broad market.

1.Application of PEI in the field of communication

PEI materials are used as optical communications with fiber optic connectors, optical transceiver module optical components, RF connector insulators, base station cavity filter plastic cavity, filter tuning screws, antenna internal fixing screws, ring phase shifter bracket, etc. In addition, foaming PEI materials in the millimeter-wave radome also has advantages.

PEI for communications

2.PEI aerospace applications

PEI can be used in aerospace, such as air and fuel valves, food tray containers, steering wheels, internal cladding and a variety of structural components, etc.; PEI unidirectional belt can be used in seat frames and luggage compartments.

3.PEI automobile applications

PEI can be used in automobile control valves, oil pumps, lights, LIDAR, fenders and other components, PEI film can be used as a capacitor of high temperature dielectric film.

PEI for automotive parts

4.Application of PEI in medical field

PEI can be used in medical equipment. Such as ventilators, anesthesia machines, sterilization trays, surgical guides, pipettes and laboratory animal cages.

In summary PEI used in laboratory animal cages, Figure source network

In addition, PEI is also used in home appliances, microwave oven serving trays, and eyeglass frames. As you can see, PEI is indeed a powerful and versatile material.

Manufacturer Trade Names

Duratron ® U 1000 PEI Unfilled

Duratron ® U 2100 PEI 10% Glass

Duratron ® U 2200 PEI 20% Glass

Duratron ® U 1000 PEI Unfilled

Semitron ® ESd 410 C PEI

Semitron ® ESd 420 PEI

Semitron ® ESd 420 V PEI

SustaPEI GF 30 ULTEM ® 2300

SustaPEI MG (Medical Grade) ULTEM ®

SustaPEI ULTEM ® 1000

TECAPEI ® Unfilled PEI

ULTEM ™ 1000 Black PEI

ULTEM ™ 1000 Natural Unfilled PEI

ULTEM ™ 2100 10% Glass Filled PEI

ULTEM ™ 2200 20% Glass Filled PEI

ULTEM ™ 2300 30% Glass Filled PEI

HONY Plastics & PEI

We stock all commercially available grades of manufacture trade PEI sheet, rod, tube and film and offer cut to size, same day shipping on all inventoried manufacture trade PEI materials.

Our entire inventory of ULTEM™ PEI is coded for full traceability, we offer manufacturer certs. and C of C`s upon request at the time of order for all orders.

We specialize in plastics-only machining, including ULTEM™ PEI machining and produce CNC machined ULTEM™ PEI parts for prototype to production quantities.

We also specialize in technical services for ULTEM™ PEI materials and parts that include material selection by application, improved part design assistance, onsite consultation and more.

We stand ready to put our 15 years of combined experience and services to work for you sales@honyplastic.com

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.