Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PVDF, homopolymer of 1,1-difluoroethylene or copolymer of a small amount of modified monomer and VDF, semi-transparent or white powder or granule with excellent properties such as solubility, crystallinity and thermal stability.

The English name of PVDF is poly(vinylidene fluoride), and the Chinese name is Polyvinylidene fluoride, also known as polyvinylidene fluoride. PVDF is the second largest product in the fluoroplastic family, due to PVDF has good processing performance, so in recent years has been rapid development. PVDF anti-corrosion products can be used as valves, pipeline lining, can also be made into a full plastic parts, PVDF as raw materials for the manufacture of large-scale equipment can reach 10m in diameter and can be made into blisters, structural complexity of the filler and other shaped parts.

Polyvinylidene fluoride is a crystalline polymer with low melting point, high mechanical strength, wear-resistant, cut-resistant, high temperature-resistant, corrosion-resistant and high dielectric constant. In addition, PVDF has excellent weather resistance, UV resistance, radiation resistance and processing performance. Meanwhile, PVDF has low processing temperature and good melt flow, which can be used to make tubes, plates, rods, films, fibers and all-plastic valves.

PVDF has good gas barrier, special piezoelectricity, thermoelectricity, etc. It is used in building anticorrosive, weather-resistant coatings, chemical anticorrosive, piezoelectricity materials, hanging fish line, etc.

Material Properties:Appearance of translucent or white powder or particles, tightly arranged between molecular chains, and strong hydrogen bonding, oxygen index of 46%, non-combustible, crystallinity 65% ~ 78%, density 1.17 ~ 1.79g/cm3, melting point of 172 ° C, heat distortion temperature of 112 ~ 145 ° C, the long-term use of the temperature of -40 ~ 150 ° C. The material has a good gas barrier, special piezoelectricity, thermoelectricity.

The main application areas are:

Photovoltaic backsheet: Fluorinated backsheet films used in photovoltaic field mainly include PVF and PVDF films. Compared with PVF film, PVDF film has more excellent performance in UV resistance, chemical resistance, flame retardant, wind and sand resistance, recyclability, densification, etc., which can better protect photovoltaic cells.

Lithium battery: PVDF has excellent corrosion resistance and chemical stability, and it is mainly used as positive binder in potassium batteries, and there is no suitable alternative at present. In addition, PVDF can also be used to manufacture potassium battery diaphragm and diaphragm coating.

Coatings: PVDF made coatings are resistant to oxidation and optical degradation, do not fade, can withstand air, water, mold, acid and alkali, salt spray, etc., the service life of more than 30 years, without maintenance, has a high cost-effective, is the ideal decorative material for the roof of the building's exterior wall and a variety of building materials.

Water treatment: PVDF hollow fiber membrane has excellent chemical properties with good pollution resistance, oxidation resistance and has good tensile strength and high water throughput, can be used in industrial wastewater, domestic wastewater treatment, seawater purification and other water treatment fields.

Chemical industry: PVDF chemical resistance, excellent processability, fatigue and creep resistance, chlorine, Australia halogen and halogen compounds have excellent resistance characteristics, so PVDF is the petrochemical and other industrial equipment, fluid handling system as a whole or lining pumps, valves, piping, piping fittings, tanks and heat exchangers, one of the best material.

Semiconductor: Semiconductor manufacturing has very high material requirements for related equipment, mainly including roughness, chemical stability, electrical insulation, etc. PVDF has low surface energy, good corrosion resistance, good electrical insulation performance, and can be used for storage and transportation of high-purity chemicals, filter housings and other components.

Medical Devices: PVDF is safe and harmless, and can be used in the field of medicine.PVDF can be made into a variety of porous and non-porous materials, and can also be made into biological materials. For example, PVDF can be made into artificial blood vessels, Archimedes spiral water purifiers, and pharmaceutical packaging materials to replenish gas cancer tablets.

Wire and cable: PVDF has insulation, corrosion resistance, self-extinguishing, low density, waterproof, aging resistance and easy to process, can be used for the manufacture of special wires and cables, connectors, sheaths, cathodic protection jacket, etc., for corrosion-resistant requirements of the place, high-rise buildings, military and aerospace devices.

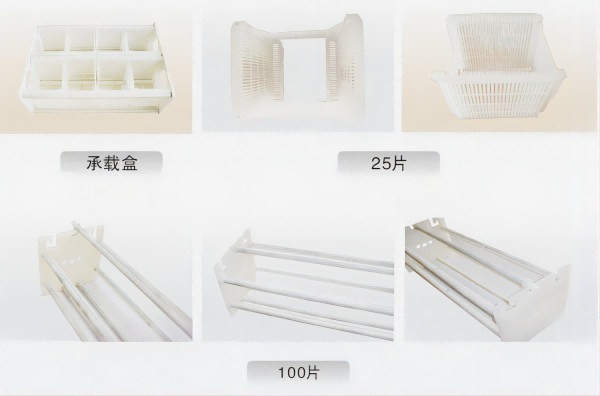

PVDF material solar cell wafer carrying flower basket features

Specification, mm : 25-piece set, Capacity/piece : 25, Slot spacing : 4.76, Distance between narrow slots : 1.52, Overall profile length : 143.5, Overall profile width : 152, Overall profile height : 149 Wafer carrier.

The solar cell wafer basket carrier and accessories made of PVDF are suitable for loading square solar cell wafers with specifications of 125×125mm and 156×156mm, which can be used for both mechanical and manual cleaning and equipped with protective strips.

This series of wafer flower basket products have strong rigidity and strength, external dimensions, in the 150 ℃ below the acidic, alkaline cleaning solution for long-term use will not be deformed, and the cleaning solution is not contaminated, the loading of wafers does not scratch the wafers, to meet the requirements of the production process of solar cells.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.