Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

What is PCTFE (Polychlorotrifluoroethylene) and what are its properties and uses?

Polychlorotrifluoroethylene (PCTFE) Chinese name: polychlorotrifluoroethylene English name: polychlorotrifluoroethylene, PCTFE. polymer of chlorotrifluoroethylene. Abbreviation PCTFE, short for trifluoro (F3). Melting temperature of 213 ℃, with excellent chemical stability, insulation and weather resistance, can be used in -196 ~ 125 ℃ for a long time, mechanical strength and hardness is better than Polytetrafluoroethylene, made of film has a better transparency and lower air permeability rate.PCTFE is a crystalline polymer, melting point of 425F, density of 2.13g / cc (grams / cubic centimeter). ). Shore hardness D85.

PCTFE is a fluorine material that can be processed by hot-melt and is of course a thermoplastic.

PTCFE materials are characterized by high hardness and outstanding creep resistance, as well as very low permeability to water vapor and gases, and PCTFE also has a remarkable feature of excellent radiation resistance.

The main use of PCTFE material is as anti-corrosion lining for chemical tanks, valves, pumps, etc., as well as in products such as pipe fittings and test vessels. At the same time, PCTFE can also be used in electronic seals, wear-resistant gears, and radiation-resistant products.

There are various processing methods, in addition to thermoplastic processing and molding, it can also be processed into plates and rods for secondary cutting and processing into high precision machine parts.

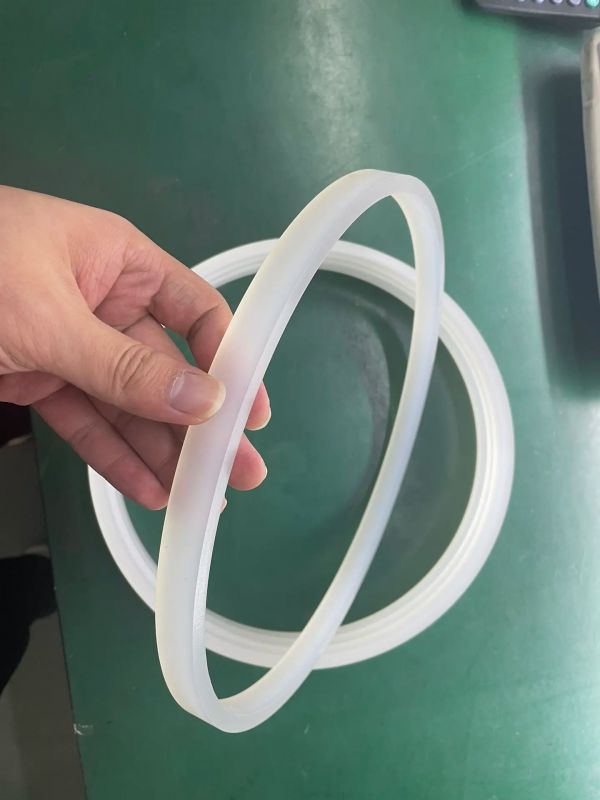

Polychlorotrifluoroethylene Gasket Low Temperature Resistant PCTFE Gasket LNG Deep Cooling Gasket

Polychlorotrifluoroethylene, abbreviated as PCTFE, is a polymer compound made from trifluoroethylene by polymerization. Low molecular weight is liquid or wax-like. High molecular weight is white solid or dispersed liquid. Solid density 2.1~2.2, melting point 208~210℃. Resistant to heat, acid, alkali and organic solvents (except halides), but not resistant to molten caustic and elemental fluorine. Chemical resistance is second only to PTFE. It can be used as engineering plastics.

Tensile strength 3.096~4.135 MPa (316~422 kgf/cm2). Generally used in chemical equipment with high performance requirements, insulated cables, radio appliances, capacitors and heat or low temperature resistant fittings. Dispersions are used to make anti-corrosion coatings and films.

The synthesis methods of PCTFE include polymerization, solution polymerization and dispersion polymerization, etc. It is prepared by free radical polymerization with peroxide as initiator.

Polytrifluoroethylene has excellent chemical stability, insulation and weather resistance, can be used for a long time at -196 ~ 125 ℃, mechanical strength and hardness is better than polytetrafluoroethylene, made of film has a better transparency and lower air permeability rate.

PCTFE is suitable for use in contact with strong corrosive media, high-pressure system of sealing and gasket materials, observation window transparent materials, and electrical Insulation Materials, etc., so there is a special significance in the chemical industry, atomic energy industry, but its price is more expensive than PTFE. Low molecular weight polytetrafluoroethylene has high density, excellent viscosity-temperature characteristics and chemical resistance, and can be used as sealing fluid for highly corrosive media, lubricating grease and balance fluid for navigating gyroscope.

PCTFE has the rigidity, low-temperature resistance, cold flow resistance, is the ideal sealing material for low-temperature and high-pressure working conditions, and has special uses in high-tech fields.

Applications:

1, contact with strong corrosive media, high-pressure system sealing and gasket materials, observation window transparent materials, etc..

2.Electrical insulation materials, etc.

3.Low molecular weight PCTFE is used as sealing fluid of high corrosive medium, lubricating grease and balance fluid of navigation gyroscope.

HONY Plastic has various specifications of PCTFE rods, tubes and plates as well as sealing gaskets, gaskets, valve seats and so on. Specific specifications refer to PTFE products specifications (PCTFE products in line with the relevant corporate standards).

PCTFE products Item Unit Value

Density g/cm3 2.10-2.18

Tensile strength Mpa ≥ 30

Elongation at break % ≥20

Continuous use of high temperature ℃ -200-150

Dielectric strength Kv/mm ≥ 15

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.