Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

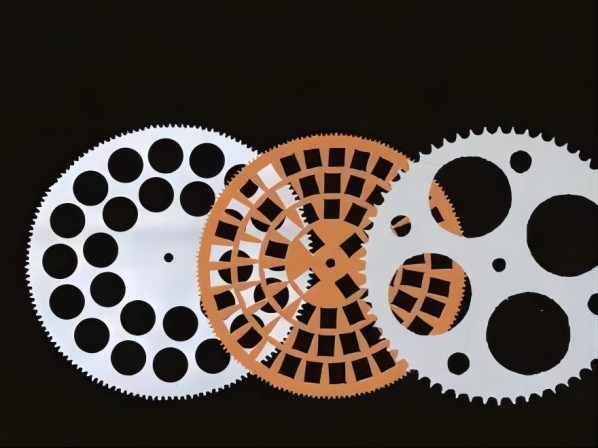

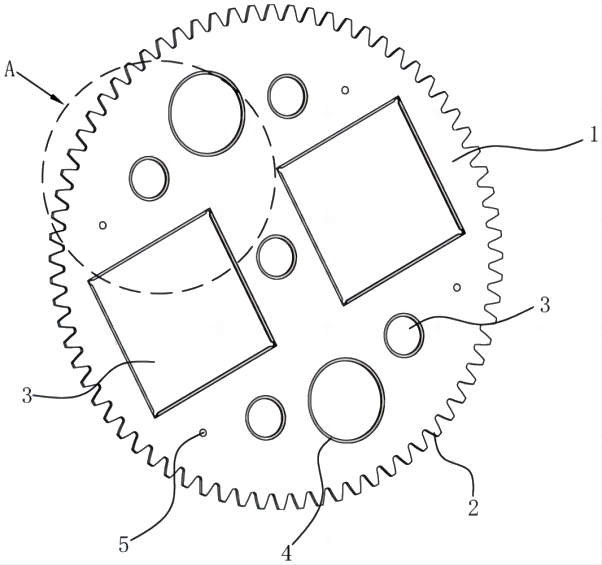

The glass fibre material planetary wheels, also known as polishing pads, polishing fixtures, etc., are fixtures used in various flat polishing processes such as silicon wafers, hard discs, glass, lenses, and so on. Because of its manufacturing process, the process requirements are high, and the finished product is fine, generally using precision engraving machine and other precision machining equipment for processing.

Currently the main material for the planetary wheel FR-4 glass fibre plate, a combination of various characteristics, glass fibre plate is currently on the market more suitable for the manufacture of planetary wheel materials, such as: wear-resistant, easy to process the molding process is simple, do not hurt the polished workpiece and other advantages.

High-quality glass fibre plate (FR-4) material properties: high temperature resistance of 180~200℃, high mechanical, high dielectric properties, high temperature resistance, moisture resistance, smooth surface, good workability.

The finished product has very high processing precision, which can be controlled within 0.02mm, and the cut surface is very smooth and clean, there will not be any burrs, and even the traces of processing cannot be seen.

Stable electrical insulation properties, smooth surface, no pits, standard thickness tolerance, suitable for high-performance electronic insulation requirements of the products, such as FPC reinforced boards, PCB drilling spacers, glass fibre interfaces, potentiometer carbon film printed glass fibre fibre boards, precision star wheels (used in lenses, silicon wafers, etc.).

Precision parts process, the manufacturer is also a challenge, so for the finished product of the star wheel requirements are also very fine, even now, there are still many factories using moulding method to produce the star wheel, the reason is just because it is very low production costs, and polished workpiece there is no need to choose the stamping production; but the production of this type, then you will face, the loss of large products, and the problem of more rough.

The following take a look at, the tourmaline wheel applicable to which industries: tourmaline wheel

①Silicon single crystal, sapphire chips, optical glass, windows, crystals, ceramics, piezoelectric crystals, quartz wafers, displays, gallium arsenide, automotive parts, such as thin brittle metal or non-metal grinding, polishing.

② Resin vernier sheet its wear-resistant, smooth, no iron powder grinding advantages and metal abrasives are different, it can ensure that the accuracy of the product smooth, undamaged, grinding effect is surprisingly good, especially suitable for optical lenses, gemstone surface polishing and grinding. Traveller Wheel

③Piezoelectric crystal, magnetic materials. Tourbillon wheel

④Two-side grinding, two-side polishing machine used in the abrasive.

Swimming star wheel work, high-speed operation, the need to polish the surface of the product to produce rolling and micro-cutting force, uneven places slowly become flat, later bright can be seen. Two substances rubbing each other will produce high temperature, the loss is also very large.FR4 epoxy star wheel high temperature resistance, wear resistance, high strength, light weight, corrosion resistance, good toughness, in high temperature is not damaged, a long time friction before a certain amount of wear and tear, long service life.HONY plastic use imported CNC machining equipment to process the star wheel. The drawing is converted into a code and entered into the computer can be automatically produced, the production time required is short, high efficiency, the size of the product and the size of the drawing on the error of 0.03mm controllable range.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.