Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Which one is better, FR4 epoxy board, 3240 epoxy board or epoxy fiberglass board?

FR4 epoxy board, 3240 epoxy board, and epoxy fiberglass board are all insulating boards. They all have insulation properties such as insulation strength, electrical breakdown voltage, and high temperature resistance, but they are divided into high and low.

FR4 epoxy board is a plate-shaped insulating material made of fiberglass cloth soaked in epoxy resin as an adhesive, dried and hot-pressed. It has high mechanical properties, water absorption, flame retardancy and heat resistance, and its dielectric properties are stable after immersion in water. The fr4 epoxy board has strict requirements in the manufacturing process. Its thickness tolerance is generally controlled within 0.02, and it is flame retardant. Grade V0, mostly used in electronic and electrical insulation parts, aircraft, high-speed trains, transformer insulation panels, precision starwheels, etc.

3240 epoxy board is made of fiberglass cloth bonded with epoxy resin and heated and pressed. The model is 3240. It has high mechanical properties at medium temperatures and stable electrical properties at high temperatures. It is suitable for high-insulation structural parts used in machinery, electrical appliances and electronics. It has high mechanical and dielectric properties and good heat resistance and moisture resistance. Heat resistance grade F (155 degrees).

The insulation properties of epoxy fiberglass board and fr4 epoxy board are basically similar in terms of insulation strength, electrical breakdown voltage and high temperature resistance, but they are inferior in flame retardant level and can only reach flame retardant V2 level.

Through the production process, materials and performance analysis of the above three types of insulation boards, it is not difficult to find that fr4 epoxy board is higher than 3240 epoxy board and epoxy fiberglass board in every performance.

The difference between epoxy board and fiberglass board

1. Different materials

Epoxy board is a composite material made of epoxy resin and glass fiber reinforced materials. It has excellent heat resistance, corrosion resistance, high mechanical strength and other properties. Fiberglass board is an inorganic non-metallic material made of glass fiber as raw material and formed by molding or extrusion.

2. Different characteristics

2.1 The strength and stiffness of epoxy board is better than that of fiberglass board, and it has better load-bearing capacity.

2.2 The wear resistance and temperature resistance of epoxy boards are better than those of fiberglass boards, and they have a longer service life.

2.3 Epoxy board has good processing performance and can be processed through injection molding, extrusion, molding and other methods.

2.4 The cost of fiberglass boards is relatively low and is suitable for cost-sensitive occasions.

3. Different application

3.1 Epoxy boards are mainly used in electronic appliances, aerospace, chemical industry and other fields, and are often used to manufacture high-strength, high-corrosion-resistant parts, Insulation Materials, etc.

3.2 Fiberglass boards are often used in construction, ships, automobiles and other fields to manufacture ceilings, walls, partitions, car bodies, etc.

Generally speaking, although there are certain differences between epoxy boards and fiberglass boards in terms of materials, characteristics, uses, etc., they are both very important and play an important role in industry and life. In practical applications, different materials need to be selected according to specific usage scenarios.

What are the differences between fiberglass board, epoxy board and FR4 board?

You may already know a lot about insulation materials, but do you know the differences between fiberglass boards, epoxy boards, and FR4 boards? Today HONY plastic will take you to understand the relevant knowledge ~ explain it to you in detail.

1. Different application. The main raw materials for the production of circuit boards are alkali-free glass cloth, fiber paper, and epoxy resin. Fiberglass board: base material fiberglass cloth, epoxy board: binder is epoxy resin, FR4: base material cotton fiber paper. All three are fiberglass boards.

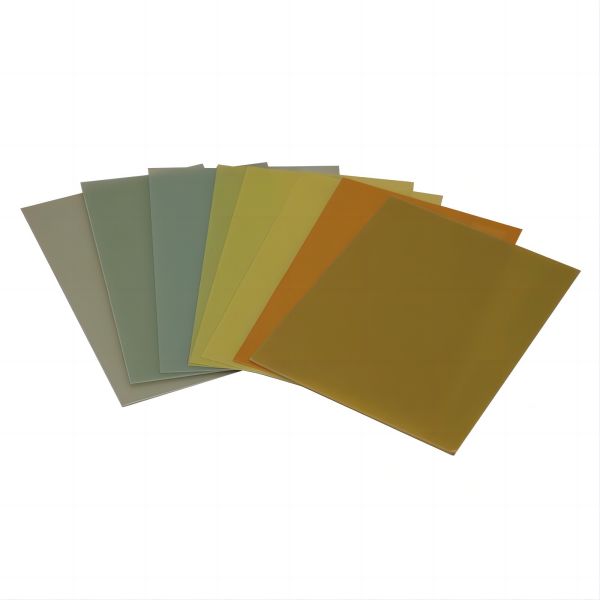

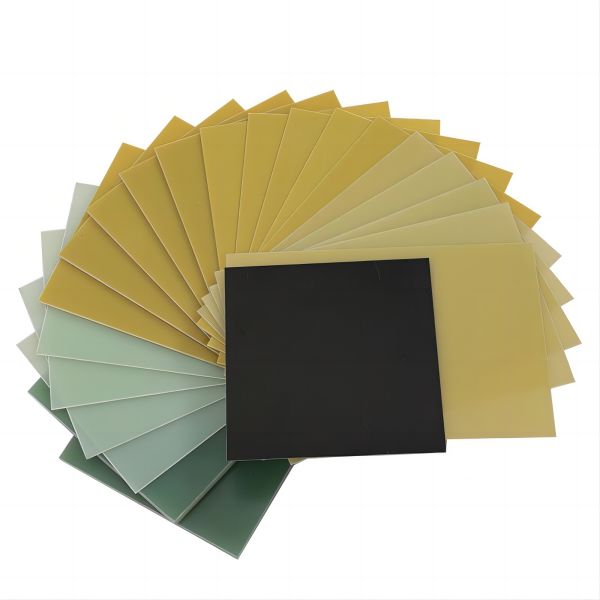

2. Different colors. Usually the epoxy board on the market is phenolic epoxy, which is yellow. Not used as base material for hard circuit boards or electrical insulation. FR4 is a NEMA standard pure epoxy sheet. The normal color is dark green, which is the color of epoxy.

3. Different properties. Fiberglass board has the characteristics of sound absorption, sound insulation, heat insulation, environmental protection, flame retardant and so on. FR-4 is also known as fiberglass board; fiberglass board; FR4 reinforced board; FR-4 epoxy resin board; flame retardant insulation board; epoxy board, FR4 light board. Epoxy glass cloth board; circuit board drilling pad.

Features of fiberglass board:

The main technical features and applications of white FR4 light board: stable electrical insulation performance, good flatness, smooth surface, no pits, thickness tolerance exceeds the standard, suitable for products with high performance electronic insulation requirements, such as FPC reinforcement boards, soldering furnaces High temperature resistant plate, carbon diaphragm, precision starwheel, PCB test frame, electrical (electrical) equipment insulating partitions, insulating pads, transformer insulating parts, motor insulating parts, deflection coil terminal boards, electronic switch insulating boards, etc.

It is also what everyone calls fiberglass board. It is generally used as a soft base layer, and then wrapped with fabric, leather, etc. to make beautiful wall and ceiling decorations. The application is very wide. It has the characteristics of sound absorption, sound insulation, heat insulation, environmental protection, flame retardant and so on. The above is a little knowledge about the differences between fiberglass boards, epoxy boards, and FR4 boards. If you have any questions, please feel free to communicate with honyplastic Insulation.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.