Commonalities and differences between PPS rods and POM rods

July 13, 2023

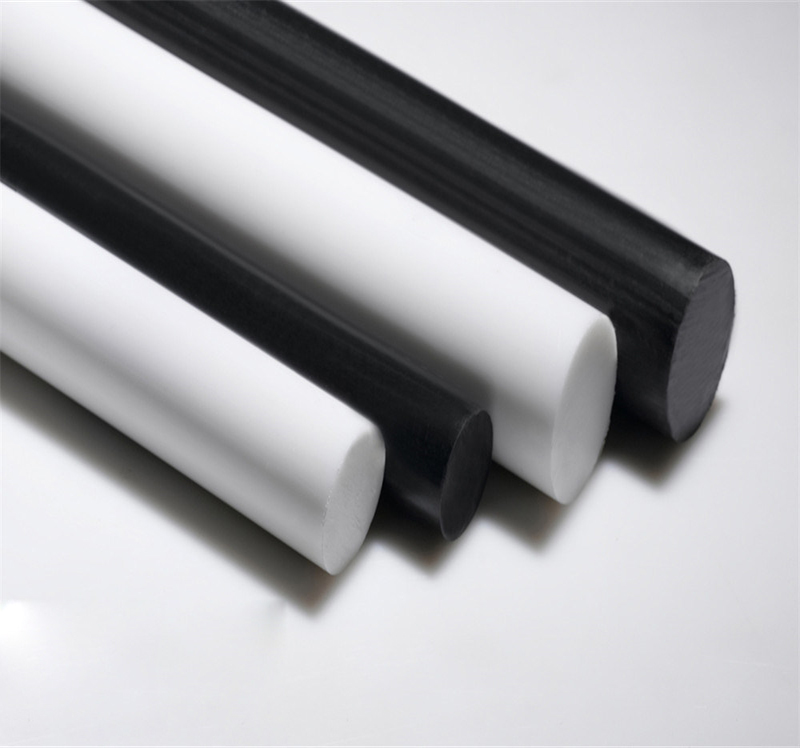

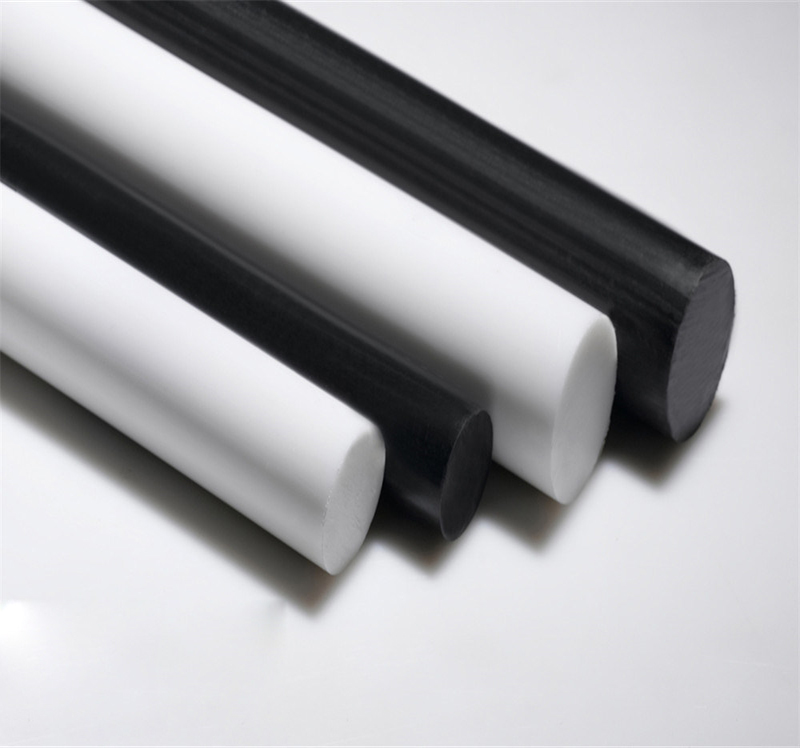

Commonalities and differences between PPS rods and POM rods 1. What is PPS rod? PPS rod English name: Polyphenylene Sulfide, PPS rod is also known as (polyphenylene sulfide) is a crystalline highly rigid white powder polymer, high heat resistance (continuous use temperature up to 220-240 ° C), mechanical strength, rigidity, flame retardant, chemical resistance, electrical properties, dimensional stability are excellent resins, abrasion resistance, creep resistance, flame retardant excellent. Self-extinguishing, up to UL94V-0 grade. High temperature, high humidity still maintain good electrical properties. Good mobility, easy molding, molding almost no shrinkage holes and concave spots. Good affinity with various inorganic fillers. Advantages: PPS rods have high mechanical strength. Rigid, outstanding low abrasion, impact resistance and chemical resistance is better than PSU and PE.PPS rods comply with OSU standards very good resistance to chemical oxidation and hydrolysis, can be made to repeat steam boiling. Fire self-extinguishing plastic. PPS rods have a very high service temperature, can still be resistant to high corrosion at 230 ℃, can be used briefly up to 280 ℃. PPS rods at this temperature its flexural strength and room humidity ABS similar, low shrinkage, excellent dimensional and thermal stability, physiological use of the undoubtedly. PPS rods because of the low water absorption, resulting in very small dimensional changes. PPS rods have very excellent dimensional stability. PPS is an engineering plastic with excellent machinability, and it is not easy to work with PVC and PTFE, PEEK, etc., even though it can be processed by solvent bonding. It is necessary to have skillful welding technology to weld with PTFE and PEEK. Applications: Electronics, electrical: micro-electronic components package, coil skeleton, motor casing, relays, fine-tuning capacitors and other parts. Precision instruments: computers, timers, photocopiers, temperature sensors and a variety of measuring instruments shells and parts. Machinery: pump shells, pump wheels, valves, fans, flow meter parts, flanges, universal heads, etc. Automobile: ignition, clutch, transmission, gear box, bearing support, exhaust system parts. Household appliances: protective coatings and parts for hot air blower, curling iron, hair dryer, hair iron, rice cooker, etc.  2.What is POM rod? POM rod (polyoxymethylene crystalline): English name Polyoxymethylene, commonly known as steel rods, steel rods, steel rods, super steel rods are made of POM plastic particles through the extruder high temperature extrusion, extrusion through the corresponding mold mouth to get a different thickness of the rod. It is a thermoplastic engineering plastic with high hardness and high crystallinity.

2.What is POM rod? POM rod (polyoxymethylene crystalline): English name Polyoxymethylene, commonly known as steel rods, steel rods, steel rods, super steel rods are made of POM plastic particles through the extruder high temperature extrusion, extrusion through the corresponding mold mouth to get a different thickness of the rod. It is a thermoplastic engineering plastic with high hardness and high crystallinity. Advantages:

Good mechanical properties: POM rods have high strength, stiffness and hardness, and are a harder plastic material that can withstand greater tensile, bending and compressive stress.

Nice abrasion resistance: POM rods have smooth surface, good abrasion resistance and fatigue resistance. It can maintain stability for a long time even under high speed movement. Excellent chemical resistance: POM rods have very good chemical resistance and can resist the erosion of weak acids, weak bases and organic solvents within a certain range and maintain their excellent physical properties. Good processing performance: POM rods have low density, have good processing performance, easy to cut, grind, mill and molding processing, can provide a wide range of options for different processing techniques. Decent insulating properties: POM rod is a good insulating material, will not be eroded by moisture, has excellent electrical insulation and dielectric properties, often used in electronic and electrical fields. Good hydrolytic stability: POM rods are heat-resistant, not easy to decompose, and will not produce odor and harmful substances due to decomposition during processing. Polyformaldehyde has excellent physical, mechanical, thermal and electrical properties, resistance to organic solvents, abrasion resistance, creep resistance, fatigue resistance and other properties, widely used in place of a variety of non-ferrous metals and alloys to make automobiles, machinery, instrumentation, agricultural machinery, chemical parts. Such as gears, cams, bearings, bushings, washers, valves, liquid transportation pipes, handles and chemical solvents. Especially in the automobile industry, a large number of used in the production of universal axis, carburetor; in the construction of the production of faucets, agricultural sprayer spray, agricultural sprayer components, audio-video tapes, tape reels, photographic equipment and a variety of precision instrument components, and so on. Application: POM is widely used in the manufacture of a variety of sliding rotating machinery, precision parts, gears, bearings and so on. The use of industry throughout the automobile, toys, children's cars, electronics, clothing, medical care, machinery, sports equipment and other fields.  3.The commonality and difference between PPS bar and POM bar: Commonality: both profiles are polymer / high rigidity / high strength thermoplastic engineering plastics, both have high mechanical properties and dimensional stability, as well as good surface hardness, high wear / fatigue resistance, are more suitable for mechanical transmission parts.

3.The commonality and difference between PPS bar and POM bar: Commonality: both profiles are polymer / high rigidity / high strength thermoplastic engineering plastics, both have high mechanical properties and dimensional stability, as well as good surface hardness, high wear / fatigue resistance, are more suitable for mechanical transmission parts. Difference: different working temperatures, PPS rods long-term temperature in the 180-220 degrees between long-term work, and POM rods working temperature is only 80-100 degrees; acid and alkali resistance is different, although POM can also be resistant to part of the acid and alkali and solution but with PPS compared to its acid and alkali / corrosion-resistant range is relatively narrow, in the known thermoplastic engineering plastics, PPS acid and alkali resistance has the most extensive and high stability; electrical properties are different, PPS has high mechanical properties and dimensional stability, as well as good surface hardness, high wear resistance / fatigue resistance, are more suitable for mechanical transmission parts. High stability; electrical properties are different, POM rod voltage resistance is only 15KV, dielectric constant is 3.8, PPS rod voltage resistance is 25KV, dielectric constant is 3.2; fatigue and self-lubricating strength is different, PPS rod has a high self-lubricating properties, especially without lubrication under the conditions of the coefficient of friction to maintain a lower and heat-resistant does not fall out of the skin, POM rods are prone to fatigue performance decline and prone to high temperature and high load conditions. POM rods are prone to fatigue performance decline and easy to peel.