Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

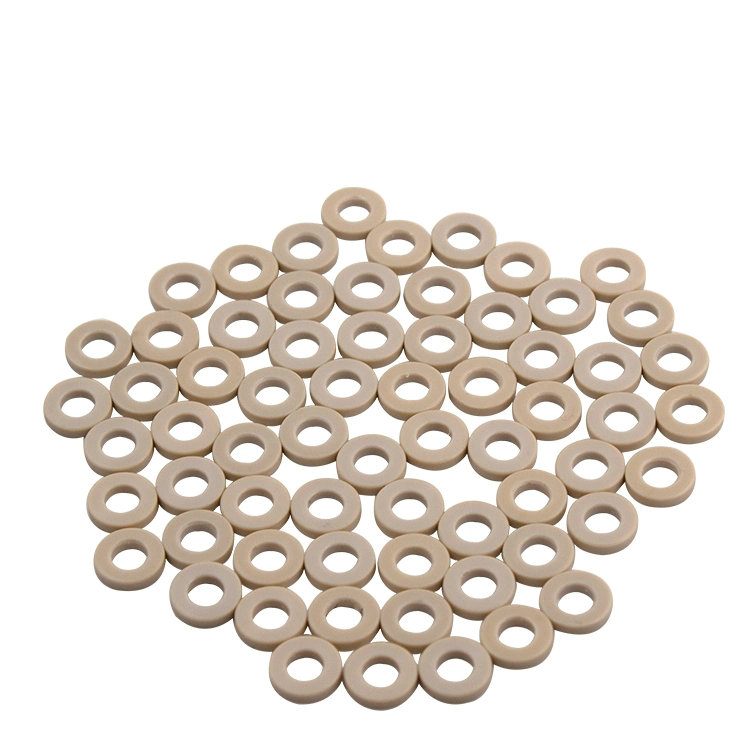

Mechanical Seal Princess——Special Engineering Plastic PEEK Gasket

There are thousands of gaskets. Why is the PEEK gasket so special that it can be called a mechanical queen?

The reason why gaskets are used to seal is that the machined surface cannot be perfect and irregular, and gaskets can be used to fill the shortage to prevent pressure between two objects, corrosion, and natural thermal expansion and contraction of pipes. mechanical seal between objects.

Ordinary gaskets are usually made of sheet materials, and the material of the gasket will be changed according to the different things to be sealed, such as pad paper, rubber, silicone rubber, metal, cork, felt, neoprene, nitrile rubber, Glass fiber or plastic polymers are commonly used materials, and the excellent comprehensive performance of PEEK can well meet these needs. Peek gaskets have good sealing performance, particularly high gasket delivery rate, excellent chemical resistance, and are non-toxic. Tasteless, odorless, acid-resistant, not easy to deteriorate, compared with metal gaskets, it has excellent insulation, corrosion resistance, heat insulation, non-magnetic properties, light weight, and is widely used in all aspects.

The continuous use temperature of the gasket of PEEK material is extremely high (about 260 degrees), and it also has extremely high rigidity and hardness, as well as unique high tensile strength and fatigue strength, high creep strength, excellent dimensional stability, Excellent anti-ultraviolet performance, excellent high-energy radiation resistance, especially suitable as gasket materials, not only these, but also many special engineering plastics such as PPS, PEI, etc. are also suitable.

November 15, 2024

November 14, 2024

August 27, 2021

August 26, 2021

November 13, 2024

November 03, 2024

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 15, 2024

November 14, 2024

August 27, 2021

August 26, 2021

November 13, 2024

November 03, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.