Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PEI (Polyetherimide) Material Introduction

Product Overview Product Characteristics Application Fields Performance Parameters

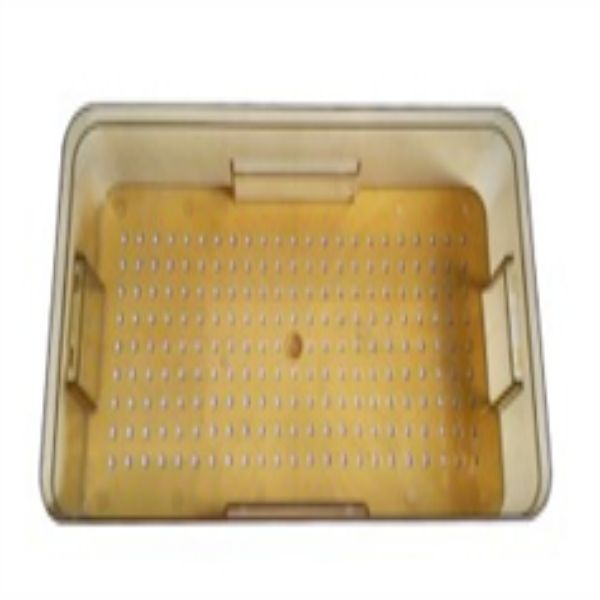

PEI polyetherimide is a transparent amber-colored amorphous thermoplastic special engineering plastics, English name: Polyetherimide, abbreviated as PEI. its molecular structure contains both aromatic amine functional groups and ether bonding structure, compared with other aryl Polyimide (abbreviated as PI) is a lower cost, higher yield of thermoplastic PI. in addition, PEI can be further improved through the addition of glass fiber modification. In addition, PEI can also be modified by adding glass fiber to further enhance its performance.

01 PEI Product Overview

PEI is a pure polyetherimide (PEI) profile. PEI is an amorphous polymer with a glass transition temperature of up to 215°C. It has mechanical properties comparable to those of PEEK, as well as excellent thermal, insulating, and flame-retardant properties. It can be used in high temperature environments with high stress, fatigue stress or impact stress, such as automotive parts or interior and exterior, semiconductor processes, precision bearings, mechanical load-bearing parts, wind power equipment or new energy battery parts, electrical systems.

02 PEI product characteristics

High tensile strength, strength above 110MPa

High flexural strength, strength of 150MPa or more

Excellent thermo-mechanical load-bearing capacity, thermal deformation temperature greater than or equal to 200 ℃.

Good creep resistance and fatigue performance

Excellent flame retardant properties, low smoke burning properties

Excellent dielectric properties and insulation

Excellent dimensional stability, low coefficient of thermal expansion

High heat resistance, can be used under 170 ℃ for a long time

Transmission of microwaves

Detailed performance

01 Identifying Characteristics:

Translucent amber solid plastic, modified with glass fibers to be olive in color.

02 Mechanical properties:

High tensile strength, high modulus of elasticity, modified by glass fiber, higher strength and modulus, much higher than other high-performance engineering plastics.

03 Electrical properties:

Excellent electrical properties, volume resistivity, high dielectric strength, arc resistance 128s, exceeding the UL minimum requirement of 120s for charged parts support substrate, what's more, the electrical properties of PEI can still remain basically constant in the case of changes in temperature, frequency and so on.

04 Drug resistance:

Unlike other amorphous plastics, PEI shows exceptional resistance to a wide range of chemicals. It is unaffected by most hydrocarbons and is resistant to corrosion by inorganic acids, salt solutions, and dilute bases (pH < 9). Although soluble in halogenated hydrocarbons such as trichloromethane, it is well tolerated by Freon-based cleaning agents, refrigerants, and gas-phase welding media.

05 Flame Retardant Properties:

PEI is flame retardant and low smoke, without any flame retardant, oxygen index 47, flame retardant grade up to UL94V-0 (0.4mm) and 5V (1.9mm).The CO, CO2, H2O released when PEI burns is similar to wood; the amount of smoke determined by the NBS method is 0.7 (the amount of smoke after 4min)-30 (the amount of smoke after 20min) respectively.

06 Processing performance:

Good processing performance, can make thin-walled and structurally complex products Dimensional stability: molding shrinkage is small, low coefficient of linear expansion, and the linear expansion coefficient of the metal is closer to the metal, easy to match with the metal parts, inserts. Therefore, it is widely used in the manufacture of precision products.

07 radiation resistance:

Excellent resistance to ultraviolet irradiation, in the absence of any stabilizer conditions, can withstand ultraviolet exposure, by exposure in the xenon lamp weathering test chamber 1000h, the tensile strength change is minimal;

PEI also shows good resistance to γ-ray radiation, in cobalt 60 to 1M per hour rate by the cumulative exposure of 5000M rad after the tensile strength loss of only 6%;

PEI can penetrate microwave and infrared.

08 Creep resistance:

Excellent creep resistance, even at high temperatures also has high creep resistance.

03 PEI Industry Applications

01 Electrical and electronic industry

In the electrical and electronic industry PEI's structural strength, dimensional stability at high temperatures, and constant electrical properties over a wide range of temperatures and frequencies make it the preferred material for the electrical and electronic industry. Such as the manufacture of terminal blocks, relay housings, switches, circuit boards, coil bobbins, printed circuit boards, integrated circuit bases, connectors, mirrors, fiber optic connectors and so on.

02 Mechanical industry

In the machinery industry, PEI's high strength, high rigidity, high temperature resistance and abrasion, corrosion and sealing resistance can be used to manufacture pumps, impellers, valves, gears, bearings, compression rings, gaskets and other parts in the machinery industry.

03 Medical industry

In the medical industry, PEI's toughness, high temperature resistance, and steam sterilization resistance (4,000 steam sterilizations at 130°C) are used in medical housing surgical handles, trays, fixtures, medical mirrors, and dental appliances.

04 Food Industry

In the food industry, PEI is non-toxic, odorless, non-migratory, high temperature resistant, can be sterilized, recognized by the U.S. Food Industry Association FDA, can be used in the food industry machinery parts, product packaging, toast oven, microwave ovens, tableware and so on.

05 Transportation

In the transportation industry, PEI's structural strength and rigidity, heat resistance, flame retardancy and low smoke are important factors for PEI's use in the transportation industry.PEI's sheets are used to manufacture various parts of aircraft such as nose instrument panels, interior panels, portholes, hatch coverings, baggage racks, seat brackets, and food and beverage tables, etc.; Carbon fiber reinforced PEI composites are used for structural parts of new helicopters; PEI Foam is used as thermal and acoustic Insulation Materials for airplanes; PEI is also used for automotive engine components, high-temperature connectors, high-power lights and indicators, automotive air-conditioning sensors, effective combustion temperature sensors and so on.

5G field: Optical communication equipment (infrared transmissibility), RF connectors, filters, phase shifters

In the apparel industry, PEI is also made into fibers for protective clothing for firefighters and race drivers. Nippon Woolen Corporation blends PEI fibers with wool and other materials to produce yarns, fabrics, and garments that are both comfortable and offer safety and protective qualities such as natural halogen-free flame retardancy and permanent UV protection.

05 PEI Reinforced Series

PEI GF30 is a polyetherimide (PEI) profile reinforced with 30% short-cut glass fiber. Compared to unreinforced PEI, this product offers improved strength and modulus, better abrasion resistance, and a lower coefficient of thermal expansion.

This product can be used in high temperature environments with high stress, fatigue stress or impact stress, such as automotive parts or interior/exterior, semiconductor processes, precision bearings, mechanical load-bearing parts, wind power equipment or new energy battery parts, and electrical systems.

PEI GF30 glass fiber reinforced PEI profile

Higher tensile strength, with a strength of 160 MPa or more;

Higher flexural strength, strength above 210MPa;

Excellent thermo-mechanical load-bearing capacity, thermal deformation temperature greater than or equal to 210°C;

Excellent flame retardant properties, arc resistance;

Excellent dielectric and insulating properties;

Excellent dimensional stability, low coefficient of thermal expansion;

High heat resistance, can be used for a long time at 170 ℃.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.