Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Machined parts technology is a popular manufacturing technology in recent years, its high precision, high efficiency, high stability and other advantages make machined parts are widely used in mechanical engineering, automobile manufacturing, aerospace, electronics and telecommunications and other fields. In this article, Shanghai Chengtu Plastic Products will analyze why machined parts technology is popular from technical and economic aspects.

First of all, machined parts technology is characterized by high precision. Traditional manufacturing technology is not high precision, error-prone and other issues, and the emergence of machined parts technology to effectively solve these problems, its high precision features make the machined parts size is accurate, the machining process is highly accurate, to meet the needs of a variety of fields of high precision requirements of parts manufacturing. Especially in some fields, such as aviation, aerospace, electronic communications, etc., high precision is an indispensable requirement, the high precision of machined parts technology makes it widely used in these fields.

Secondly, machined parts technology has high efficiency and high stability. With the continuous improvement of production efficiency, the machinery manufacturing industry needs more efficient machining technology to increase productivity. The advantages of machined parts technology lies in its high efficiency and stability, automated processing makes the machining of finished products with high yields, and processing speed, high efficiency. In addition, this technology has the advantage of high stability, can ensure that the same batch of processing quality uniformity and stability, and is not susceptible to the interference of external factors and errors. Therefore, machined parts technology can better meet the manufacturing requirements of modern industry.

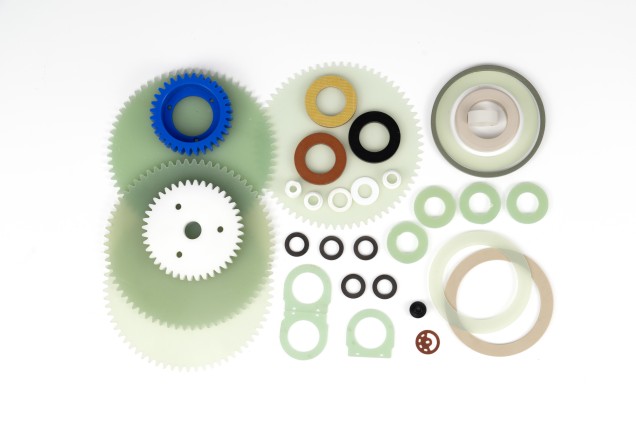

In addition, machined parts technology has a wide range of applications. Machined parts technology as one of the basic technologies of modern manufacturing, its wide range of applications, including not only the common sheet metal processing, casting processing, including precision parts processing, complex parts processing and so on. This technology can process parts made of a variety of different materials, such as steel, iron, aluminum, copper, plastics and so on. At the same time, the realization of the production of machined parts requires equipment that is simple, flexible, easy to adjust and maintain, independent of the scale of manufacturing, and therefore widely used in the manufacturing vertical.

The economic advantages of machined parts technology are obvious. With the development of the manufacturing industry, labor costs and environmental protection requirements continue to improve, the cost of traditional processing methods gradually increased, while machined parts technology can effectively reduce costs and improve efficiency. Relative to the traditional manufacturing process, machined parts technology of high efficiency, high stability, can reduce manufacturing costs and improve the economic benefits of enterprises.

In summary, the main reasons for the popularity of machined parts technology are: high precision, high efficiency, high stability, wide range of applications and economic advantages. The emergence of this technology has greatly improved the productivity and quality of the manufacturing industry and increased production efficiency, making machined parts technology play an increasingly important role in modern industrial manufacturing.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.