Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

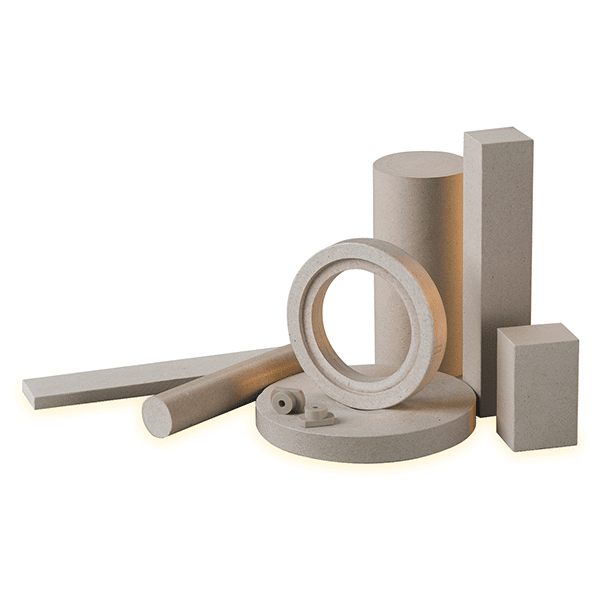

Fluorosint® PTFE Reinforced

Product description

High working temperature in air (continuous work at 260°C)The unique properties of Fluorosint PTFE Enhanced come from a special process in which synthetic mica is molecularly linked to pure PTFE through a chemical process. The performance created by this bond is beyond the reach of ordinary reinforced PTFE. Fluorosint series have good low friction and dimensionally stable properties

Fluorosint® 500 is nine times more resistant to deformation under load than unfilled PTFE. Its coefficient of linear thermal expansion is close to that of aluminum and 1/5 that of PTFE - often eliminating fit and clearance problems. It is 1/3 harder than PTFE, has better wear resistance and maintains low friction properties. Fluorosint® 500 is also not abrasive to most mating materials.

Dimensions in the dropdown menu are in inches

Applications: Bearings-seals-agitators-pumps-appliances-valve seats

Luciferin is now available in 5 grades:

Fluorosint® 500 - Excellent Dimensional Stability for Precise Dimensional Control

Fluorosint® 207 - lowest coefficient of friction of all Fluorosint grades

Fluorosint® HPV - the most wear-resistant Fluorosint grade - long-lasting low-tech PTFE-based material

Fluorosint® 135 - Excellent performance grade, stable under extreme conditions

Fluorosint® MT-01 - ultra high performance fluororesin grade, stable at high temperatures

Fluorosint® 500 PTFE

Good dimensional stability - good material selection for tight tolerances

Designed with special synthetic mica reinforcement, Fluorosint 500 exhibits good mechanical properties and low friction characteristics in addition to the chemical and hydrolysis resistance of Polytetrafluoroethylene (PTFE).

Fluorosint 500 (colour: ivory white) is 9 times stronger than ordinary PTFE in terms of deformation resistance under load pressure. Its linear thermal expansion coefficient is low, similar to that of metal-aluminum, which is only 1/5 of that of pure PTFE. Therefore, when replacing ordinary PTFE, it can solve the gap problem of ordinary PTFE when mating. Fluorosint 500 has higher hardness than pure PTFE, good wear resistance and low friction. Fluorosint 500 is a good non-abrasive engineering plastic that will not cause abrasion to most materials it meshes with.

application

Labyrinth Seals and Guards

As a wear-resistant seal, it is used on turbines. In unfavorable chemical environments, seals and shields processed from Fluorosint® 500 PTFE pipes have reliable performance and greatly improve the efficiency of turbomachinery. (Replaces previous materials: Aluminum, Bronze, Babbitt)

Transmission and Power Steering Seals

Because the service performance and service life are obviously better than other PTFE, transmission and power steering sealing rings processed by Fluorosint® 500 have been widely selected by European automobile manufacturers. (replaces previous material: GF PTFE)

Fluorosint® 207 PTFE

Fluorosint series, with low coefficient of friction

Fluorosint® 207 PTFE has good dimensional stability and excellent creep resistance, and has a unique white color. Moreover, it does not permeate in steam and complies with FDA regulations 21 CFR 175.300. Therefore, Fluorosint® 207 can be used in applications designated to comply with FDA (US Food and Drug Administration). At 150°C, the relative wear rate of Fluorosint® 207 is only 1/20 of that of PTFE, making Fluorosint® 207 a good choice for bearings and bushings working under severe conditions.

Application

Dishwasher Arm Bearings

Fluorosint® 207 PTFE can be machined into bearings for dishwasher arm bearings that provide a 20-year service life and are FDA compliant. (replaces previous material: PTFE)

seat

Fluorosint® 207 PTFE machined seat for outstanding steam and hot air performance, impermeability, good dimensional stability and low wear. (replaces previous materials: PTFE, filled PTFE)

Fluorosint® HPV PTFE

Fluorosint wear-resistant grade - PTFE material with working life beyond ordinary technology

Fluorosint HPV (Color: Brown) is a bearing grade high performance Fluorosint material - optimized for high load pressure*velocity capability and low "K" or wear factor, FDA compliant. Fluorosint HPV was developed to address work applications where conventional technical formulations of PTFE exhibit premature wear or simply are not up to the task. Moreover, Fluorosint HPV complies with FDA standards, so it gives food and medical equipment manufacturers a new material design choice, and the good load capacity and wear resistance of Fluorosint bearing grade materials also provide more advantages.

Fluorosint® MT-01

High performance grade of Fluorosint exhibiting high temperature stability

Fluorosint MT-01 PTFE (color: dark gray) is a special grade Fluorosint material, developed for working applications with high strength, stiffness and stability that ordinary PTFE materials cannot achieve. Fluorosint MT-01 PTFE maintains high mechanical properties at high temperatures, so it is often specified for applications with extreme working conditions such as valve seats, seals, and occasions prone to wear.

Fluorosint® 135

Fluorosint superior grade, stable work under extreme conditions

Fluorosint® 135 is a low coefficient of friction and deformation resistant PTFE material designed for components such as seals, bearings and gaskets. Fluorosint 135 is designed to improve the performance of compressor piston rings, support bands and packing components, avoid expensive costs caused by equipment failure, ensure production, prolong life and increase revenue, and have a price advantage.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.