Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

CNC machining encompasses a variety of tools with different functions. Without proper understanding, it is difficult to comprehend the use of these tools. An example of such tools is CNC jigs, also known as CNC workholding.

This article will demystify CNC workholding in three steps. It will show their functions and applications. It will provide reliable information about the types of CNC workholding fixtures. Finally, it will provide you with quality information on how to get the best CNC fixture design or use custom CNC fixtures.

What is a CNC fixture?

The best definition of a CNC fixture is that it is a medium for stability and positioning. It is a versatile workholding device that is primarily used to properly secure, support or mount workpieces on CNC machine tools.

CNC fixturing is an important tool for ensuring consistency and interchangeability in the manufacturing process. In other words, it facilitates a smooth manufacturing process.

You could also say that CNC workholding reduces the amount of human effort put into the manufacturing process. In this way, many people will compare them to jigs and fixtures. However, they are different. Fixtures are used to guide the movement of the tool. However, CNC workholding fixtures do not guide the tool. They only hold, support and stabilize the workpiece during the manufacturing process.

In addition, with CNC workholding, the tool moves as the workpiece moves. With fixtures, the tool remains stationary at all times.

CNC Fixturing Applications

CNC fixtures have a wide range of applications in any manufacturing industry that utilizes CNC machining. Its function is integrated with the type of CNC operation used in the manufacturing process.

It is used for CNC milling, CNC turning, CNC planning, CNC grooving and CNC grinding. This will also lead us to the types of CNC fixtures that we uncover below.

Generally, CNC jig design is responsible for its application:

Positioning

CNC workpiece fixtures ensure that the workpiece is correctly fixed to the machine relative to the machine tool. This is also to ensure that the machine surface meets the requirements.

Clamping

After positioning, CNC fixtures apply force to the workpiece to securely clamp it during any manufacturing process.

CNC workpiece fixtures utilize both of these characteristics in their function. For example, positioning and clamping play a major production role in the automotive industry. There, they protect and guide vehicles through the welding and assembly process.

Types of CNC Fixtures

Most people who are familiar with the tool don't understand the classification of CNC workpiece fixtures. Yes, things are not that simple. Since it is not simple, it is difficult for beginners to understand the idea of the tool. However, with this ultimate guide, you have nothing to fear. This section will introduce you to the types of CNC fixtures from different perspectives.

Based on CNC machining operations

There are five types of CNC fixtures based on CNC operation classification. Here is a brief introduction to CNC fixtures.

Turning Fixture

CNC turning is a CNC machining operation that removes a portion of a workpiece while rotating it in a single axis. Turning fixtures are CNC fixtures used in this process.

Milling Fixtures

CNC milling is simply a cutting CNC machining process. In this process, the computer directs the tool to cut off the desired portion of the workpiece. Milling fixtures are the CNC fixtures used in this process.

Drilling Fixtures

Drilling is a popular process in manufacturing and is more popular in CNC machining. It simply involves drilling a hole in the workpiece. The CNC fixtures used for CNC drilling are called CNC drilling fixtures.

Boring Fixtures

CNC boring is a CNC machining process in which a tool is used to expand the hole that has been drilled using CNC drilling. The fixture used in this process is CNC Boring Fixture.

Grinding Fixtures

CNC grinding involves removing a part of the workpiece with the help of a grinder. This is another popular CNC machining process used for edge cutting CNC milling. A grinding jig is a fixture that is suitable for CNC grinding process.

In general, you can draw valuable conclusions about CNC fixtures based on CNC machining operations. Each CNC machining operation that requires a jig has an operation name. Therefore, you can have others such as CNC honing jigs and CNC grinding jigs.

According to the use

You can categorize CNC workholding fixtures according to their use. There are five types of such CNC fixtures. A brief description of the five is given below.

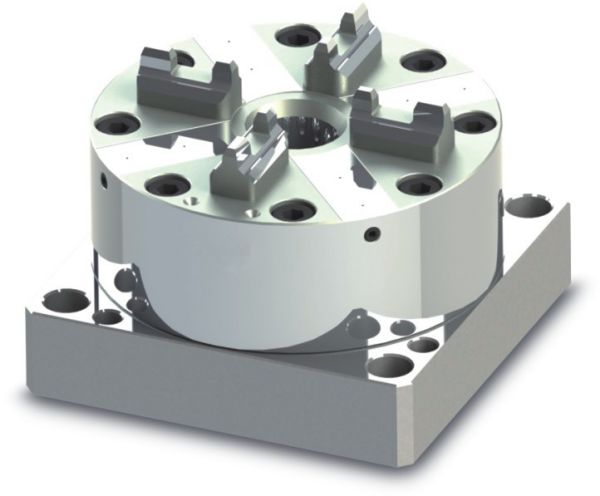

General Purpose Fixture

Universal CNC fixtures can be used for any workpiece and are easy to adjust. Each part of the fixture can be adjusted and replaced to fit any workpiece. As its name suggests, the Universal Fixture has a wide range and applications.

Specialized Fixtures

Special fixtures are CNC fixtures that fit a specific workpiece. When used with such special workpieces, they offer great advantages in terms of stability. They are also characterized by faster and easier operation during use.

Assembled fixtures

Assembled CNC fixtures only come into existence after the workpiece has been considered. The fixtures depend on the requirements of such workpieces. Assembly is carried out in a special way. As required, you can remove or reuse them as necessary.

Modular fixtures

Modular fixtures are fixtures that are easy to rebuild and reconfigure to fit any workpiece. They consist of interchangeable parts and are ideal for handling many workpieces. You can also disassemble the fixture when you are done with the process. Modular fixtures offer a better, more flexible manufacturing process.

Combination fixtures

Combination lights come in different sizes and shapes. They are ideal for handling many workpieces of different sizes and shapes depending on the machine tool.

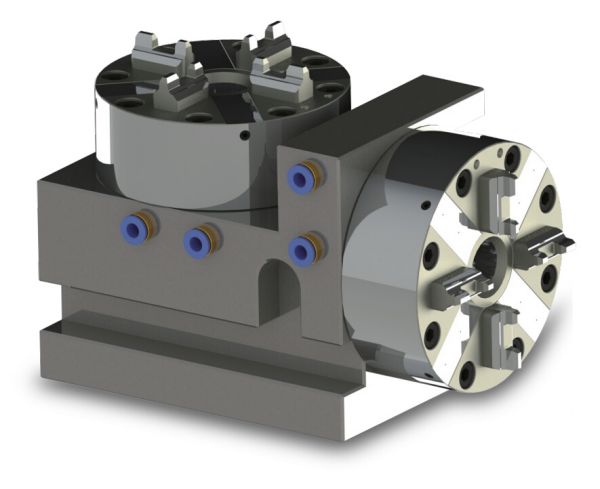

Based on their power supply

This is the last categorization process and is based on the power source of the CNC fixture. Here are the six types of CNC fixtures based on their power source.

1.Manual fixtures

2.Pneumatic fixture

3.Hydraulic fixture

4.Electrical fixture

5.Magnetic fixture

6.Vacuum fixture

What you need to know when you want to design or use CNC fixtures

There are many things you need to know about using CNC fixtures or understanding proper CNC fixture design. Here are some of the things you need to know if you already have a CNC fixture platform or need to customize your CNC fixtures.

Increase Tolerance Levels

CNC workpiece fixtures help to improve the tolerances of manufacturing operations. Therefore, it is important to ensure that they are set up to improve accuracy.

Know when to clamp

The way you clamp can have a big impact on the quality of your product. While you may think it is best to clamp to hold the workpiece in place, this is not the case.

Referring to critical surfaces

If you value less operating time, you may need to reference important workpieces on your tool. However, you should not reference many surfaces to avoid confusion.

Affordability

Another important thing to keep in mind when designing a custom CNC fixture is affordability. You need to know the number of parts you are making and the number of fixtures you will need.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.