Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

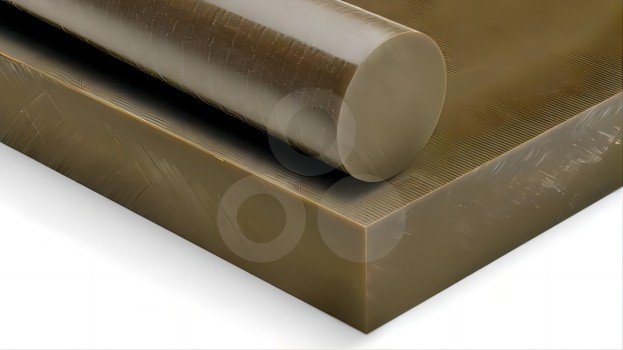

ULTEM™ PolyEtherImide (PEI) is an amber transparent high-performance polymer which combines high strength and rigidity at elevated temperatures with long term heat resistance. ULTEM™ is available in unfilled and filled grades in sheet, rod, tube, film and injection molded and machined parts.

ULTEM ™ PEI Key Properties

ULTEM™ offers excellent dimensional stability combined with broad chemical resistance. ULTEM™ is also inherently flame resistant and low smoke generating. It excels in medical reusable applications requiring repeated sterilization and is available in FDA compliant colors.

Capable of Withstanding Multiple Autoclaving Cycles

High Continuous Use Temp of 340F

High Dielectric Strength

High Heat Deflection Temperature

Hydrolysis Resistant

Inherently Flame Retardant – UL 94 V-0 Rated

UV Resistant

Low Outgassing Material

High Strength

Available ULTEM ™ Grades

ULTEM™ 1000 - is an amber transparent high-performance unfiled PEI polymer which combines high strength and rigidity at elevated temperatures with long term heat resistance. ULTEM™ 1000 offers excellent dimensional stability combined with broad chemical resistance. We offer ULTEM™ 1000 for Online Purchase in sheet and rod.

ULTEM™ 2100 - is a 10% glass filled PEI grade with improved rigidity and stiffness. This grade is less common and may require minimum runs and longer lead times.

ULTEM™ 2200 - is a 20% glass filled grade of PEI. This grade is less common and may require minimum runs and longer lead times.

ULTEM™ 2300 - is a 30% glass filled grade with improved strength and stiffness. ULTEM™ 2300 is the most common filled ULTEM™ and is readily available from stock in sheet and rod forms. We offer ULTEM™ 2300 for online purchase in sheet or rod.

Static Dissipative & Conductive PEI Grades - We offer a variety of PEI Grades formulated with static dissipative and conductive electrical properties for critical electrical and semiconductor applications. We stock the entire line of Semitron PEI grades.

Other Trade Names - Other PEI products are available as follows by the following trade names, Duratron U Series, SustaPEI, TECAPEI, ZL 1000

Common ULTEM ™ PEI Applications

Aircraft components

Analytical instrumentation Components

Electrical Connectors

Electrical Housings

Electrical Industry Components

Insulators

Medical device components

Semiconductor components

Structural Components

Ultem/PEI Machining Overview

Ultem or PEI is a high performance plastic with high mechanical strength, high stiffness, and good machinability. This material could keep narrow tolerance. For the modified plastic, HONY plastic have Ultem 2300 or PEI GF30(30% glass fiber filled), this type of material shows higher stiffness and relatively easy to machine.But all PEI plastic is prone to stress cracking, so special care should be taken in choosing a coolant.

Ultem/PEI Machining Guide

| Material | Rotate Speed (rpm) | Circular Pitch |

| PEI Virgin | 3000 | 20~24 |

| PEI GF30 | 2400~2800 | 20~24 |

| Material | Number of Teeth | Helix Angle | Approach Angle | Cutting Speed(rpm) | Feed Force(mm/r) |

| PEI Virgin | Z2 | 25 | 90 | 20~80 | 0.1~0.3 |

| PEI GF30 | Z2 | 25 | 100 | 80~100 | 0.1~0.3 |

| Material | Number of Teeth | Cutting Speed(rpm) | Feed Force(mm/r) |

| PEI Virgin | Z2~Z4 | 250~500 | 0.1~0.45 |

| PEI GF30 | Z2~Z4 | 80~150 | 0.05~0.4 |

| Material | Relief Angle | Approach Angle | Corner | Cutting Speed(rpm) | Feed Force(mm/r) |

| PEI Virgin | 10 | 0 | 45~60 | 350~400 | 0.1~0.3 |

| PEI GF30 | 6~8 | 2~8 | 45~60 | 80~150 | 0.1~0.5 |

What is the difference between Ultem 1000 and 2300?

ULTEM® 1000 & ULTEM® 2300

Ultem® is a high-performance polyetherimide (PEI) resin that has a variety of properties, including high heat resistance, strength, stiffness, and broad chemical resistance. Its resistance to most acids and bases makes it an ideal material for a wide range of applications in the industrial, automotive, and electronics markets.

There are several grades of Ultem® resin, including Ultem® 1000 and Ultem® 2300. Here we`ll explain the properties, benefits, and common applications of these two common grades.

ULTEM® 1000 & ULTEM® 2300 PROPERTIES

As a member of the polyetherimide (PEI) family, Ultem® is a semi-transparent, strong thermoplastic that can be thermoformed, injection molded, or extrusion blow molded. It functions well as electrical insulation and in high-temperature applications.

Ultem® 1000

Ultem® 1000 is a general-purpose, unfilled grade of Ultem® that offers exceptional electrical, thermal, and mechanical properties. Its limiting oxygen index (LOI) and high flame resistance make it ideal for interior aircraft components. It`s also resistant to gamma and UV radiation.

Ultem® 2300

Ultem® 2300 is a high-performance grade that is 30% glass-filled. It`s more rigid and heat-resistant than Ultem® 1000, making it ideal for applications where high temperatures or shock are common. Ultem® 2300 is also suitable for medical applications because it can withstand the high heat and steam exposure of autoclave sterilization.

KEY PROPERTIES OF ULTEM® 1000 & ULTEM® 2300

Some key properties of both Ultem® 1000 and Ultem® 2300 include:ultem

Flame retardant

Hydrolysis-resistant

Low outgassing

High dielectric strength

Suitable for continuous high-heat applications up to 340 °F

High heat deflection temperature

High strength

UV-resistant

BENEFITS OF ULTEM® 1000 & ULTEM® 2300

With such excellent thermal, electrical, and mechanical properties, using Ultem® 1000 and Ultem® 2300 comes with many benefits.

Extremely Strong and Stiff

Both grades of Ultem® offer excellent strength and stiffness up to 392 °F. Unfilled Ultem® 1000 has the same strength of other thermoplastics that contain opacifying fillers.

Easy to Thermoform

Thermoforming is the process of forming a thermoplastic sheet by applying heat and pressure to the raw plastic material. Ultem® is easy to form-with thicknesses as low as 0.2 mm-because it can withstand high temperatures.

High Dielectric Strength

Ultem® is one of the few materials that can maintain its dielectric strength at elevated temperatures. It is suitable for applications with wide frequency ranges and where a high degree of insulation is necessary.

Easy to Machine and Fabricate

Ultem® is easily machined because it retains its electrical, chemical, and thermal properties even after extensive machining or exposure to harsh conditions. Its fiber orientation enables it to withstand a lot of stress.

Resistant to Hydrolysis

Resistance to hydrolysis means that the material does not break down in water or in the presence of moisture, making it an ideal material for applications where it will be exposed to these elements.

Withstands Repeated Steam Sterilization Cycles

Ultem® is resistant to repeated sterilization cycles in a steam autoclave, meaning the material will not break down and lose its effectiveness when exposed to hot water or steam.

COMMON APPLICATIONS

Ultem® 1000 and Ultem® 2300 share common applications, such as:ultem 2

Rotors

Pumps

Manifolds

Seat fittings

Chip test sockets

Ventilation systems

Electrical connectors

Electrical insulation

Scientific equipment

Guides for electric bundles

Sensor housing and gearboxes

Medical instruments

Semiconductor equipment

For more information please refer to https://www.honyplastic.com/pei-sheet-rod/

and send inquiry to sales@honyplastic.com

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.