Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PPSU and ABS are two different polymer materials, each with its own unique properties and uses, we from the background introduction, material properties, application areas, development trends and other aspects of a detailed comparison.

Material Background

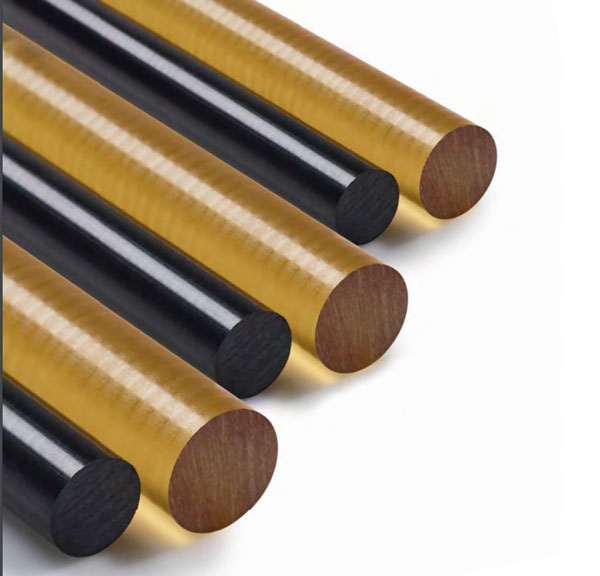

PPSU is a polymer made by alcoholysis of the condensate of p-phenylphenol and dimethyl sulfate or diethyl sulfate.PPSU has excellent physical properties, such as high temperature resistance, chemical resistance, high transparency, high weathering resistance, and high chemical resistance.

ABS is a terpolymer of acrylonitrile, butadiene and styrene, with excellent mechanical properties, thermal stability, chemical stability and processing fluidity.ABS is widely used in automotive, electrical appliances, toys and other fields.

Material Properties

PPSU has high chemical resistance and can be used in harsh environments such as strong acids and alkalis. At the same time, PPSU has a high transparency, light transmission rate of up to 90%, can be used in the manufacture of medical equipment and other products that require a high degree of cleanliness. In addition, PPSU has excellent high temperature resistance and can be used at high temperatures.

In contrast, ABS has excellent mechanical properties, impact resistance, abrasion resistance and fatigue resistance. At the same time, ABS is easy to process and can be processed by injection molding, extrusion, blow molding and other processes. In addition, ABS also has good insulation and hydrolysis resistance.

Applications

Due to the excellent performance of PPSU, it is widely used in medical devices, packaging materials, electronic appliances and other fields. Especially in the medical field, due to the high transparency and chemical resistance of PPSU, it is widely used in the manufacture of medical devices, such as syringes and infusion sets.

ABS, on the other hand, is widely used in automobiles, electrical appliances, toys and other fields. As ABS has good mechanical properties and processing fluidity, it can be manufactured with a variety of complex structural and appearance parts. In addition, ABS can also be applied to manufacture the shells of electrical products with excellent electrical insulation and weather resistance.

Development trend

With the continuous progress of science and technology, PPSU and ABS in the future application prospects are very broad.

PPSU is increasingly used in high-end medical devices, packaging materials and other fields because of its excellent performance. With the continuous progress of medical technology, the requirements for medical devices are also increasing, so the demand for PPSU will further increase. At the same time, with the improvement of environmental protection awareness, reusable and biodegradable packaging materials will also be more and more attention, and PPSU is just in line with this trend.

For ABS, at any time the development of the automobile and electrical appliances industry, its demand will further increase. At the same time, ABS can also be composite with other materials to develop more new materials, thereby expanding its application areas.

To summarize, each substance has its own use function and application field, and also has its own advantages and disadvantages. If you want to compare, the premise must be used under certain conditions or environment. Both belong to the category of plastics, the most intuitive is the temperature resistance level is different. PPSU is a special engineering plastics category, temperature resistance in the 180 ℃ or so, at present in the field of food contact containers excellent performance, such as mother and child field favored, processed into PPSU bottles, PPSU series of tableware, etc. ABS belongs to the category of ordinary plastics general-purpose plastics.

PPSU is mainly used for high temperature resistance, radiation resistance, chemical resistance and other occasions; and the price is higher than ABS. and ABS is widely used in shell parts, mechanical parts, automotive parts and other fields, is a widely used thermoplastic engineering plastics. In the choice of plastic, you need to consider the characteristics of different materials, product use and product budget.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.