Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PEEK plastic gears: the material of the future, several times stronger than metal gears

In recent years, the material revolution in the field of engineering is setting off a huge wave, PEEK (polyether ether ketone) plastic gears have become the king of materials, and is replacing the traditional metal gears at an alarming rate. the emergence of PEEK not only subverts the perception of traditional gears, but also pushes engineering applications to a whole new level.

1. Wear resistance beyond metal:

PEEK plastic gears stand out for their superior wear resistance. Compared to metal gears, PEEK's wear resistance is legendary for its ability to excel in harsh environments. Not only is it resistant to extreme temperatures, but also to corrosion and chemicals. Whether it's in the depths of the ocean or at the top of a mountain, PEEK plastic gears can hold their own.

2. Strength beyond imagination:

The strength of PEEK is breathtaking. Although it is a lightweight material, it is able to withstand high loads and is not easily fatigued. This means that PEEK plastic gears do not lose their effectiveness over time, and maintain their performance even under high speed and high frequency operating conditions.

3. Extraordinary self-lubricating properties:

PEEK material has a low coefficient of friction and can operate without external lubrication. This means that PEEK gears can reduce maintenance costs, minimize energy waste, and work more efficiently.

4. Quiet operation:

Unlike metal gears, which often produce noisy sounds, PEEK plastic gears run smoothly and operate quietly. This is especially beneficial for noise-sensitive applications such as medical equipment and office machinery.

5. Infinite innovation:

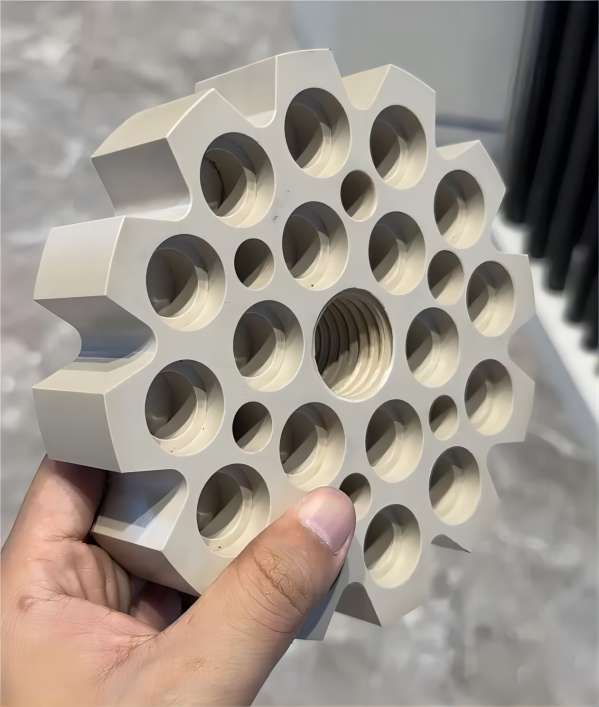

The unmatched machinability of PEEK materials makes it easy to realize complex gear designs, including internal structures and details. This allows engineers to be creative and incorporate PEEK gears into a variety of applications, from aerospace to healthcare.

6. Lightweight for high performance:

The lightweight performance of PEEK plastic gears is unmatched. It not only reduces the weight of equipment, but also increases efficiency. This is critical for lightweight design of air vehicles, automobiles and other vehicles.

Introduction to PEEK Gear Properties

The normal operation of gears depends on good friction and mechanical properties, resistance to chemical media, durability and heat resistance, as well as dimensional stability.PEEK material has an excellent combination of properties and is well suited for gear applications.PEEK materials can be molded not only by traditional machining methods, but also through precision injection molding direct molding, reducing the cost of processing and at the same time to meet the accuracy requirements.

PEEK gear performance advantages are mainly:

1, Mechanical strength at high temperatures, in 200 ℃ high temperature can still maintain sufficient mechanical strength;

2, Corrosion resistance, in addition to some of the strong oxidizing solvents, PEEK can withstand most of the solvents;

3, Lubrication-free, wear-resistant grade PEEK material for gears, can be used in high-speed, oil-free working conditions, greatly reducing maintenance costs;

4, Low moisture absorption, low water absorption, dimensional stability;

5, Low noise, relative to metal gears can effectively reduce environmental noise;

6, Food grade, can be used in the food industry, do not have to worry about metal precipitates;

Quiet, efficient solutions for the peek gear industry

When designing and fabricating a gear for a power transmission system, due consideration should be given to the value of its performance benefits and the overall cost of delivering the solution when it hits the ground. NVH metrics can be improved by using gears that reduce NVH generation compared to metal gears. Although metal gears can reduce noise propagation through the addition of moderators, the overall perceived amount of noise is still greater, which is why it is technically possible to replace metal gears with thermoplastic materials.

PEEK material is one of the higher performance thermoplastics. With its unique properties, it is well suited to extreme and demanding environments and meets the needs of a wide range of specific operating conditions, including high strength, light weight, high wear resistance, high temperature, fatigue and corrosion resistance. Together, these properties help to improve fuel efficiency, extend component life, improve comfort (smooth operation, reduced noise), and increase design freedom and cost-effectiveness.

A perfect peek gear industry solution must be judged by the following two dimensions: 1. Improve the overall noise, vibration, and comfort (NVH) of the machinery; 2. Reduce the overall mass and inertia of the parts.

Good peek gears can often reduce the clicking sound between gears and dampen noise and vibration during transmission in a way that the most complex metal gear systems can't do.

The weight of individual components and the inertia of rotating parts directly or indirectly affect the efficiency of the machinery as a whole. Most directly, reducing the overall mass will help to improve the performance of the machinery, and the use of peek gears typically reduces weight by 40% and inertia by 60% when compared to an equivalent metal gear solution.

HONY plastic machining PEEK gears

HONY plastic have a one-stop prototyping service, which can quickly, efficiently and cost-effectively achieve production goals and comprehensively shorten time-to-market. We validate the pinch performance of gears through the design of computational aids, and realize the fully automated mass production of high-performance, high-precision peek gears through machining or plastic injection molding to ensure a stable delivery cycle and provide you with professional solutions for the gear industry.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.