Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

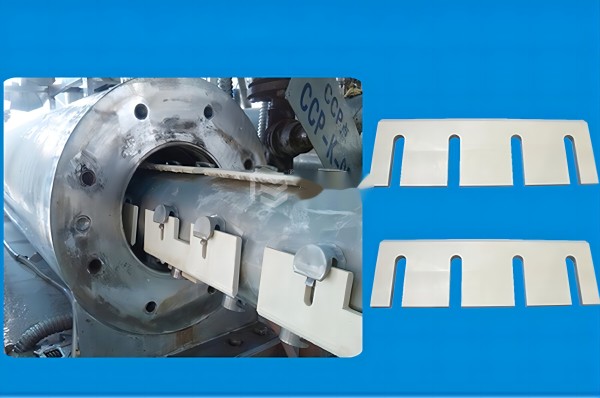

Scrapers made of PEEK: Efficiency and Quality Enhancers for Food Processing Machinery

The choice of material for scrapers, a key component in food processing machinery, is critical. In recent years, more and more manufacturers have begun to choose polyether ether ketone (PEEK) materials for their scrapers. So why are PEEK materials so popular in food processing machinery? This article explores this question in detail and reveals the multiple advantages of PEEK materials in doctor blade applications.

Excellent wear resistance

In the process of food processing, the scraper needs to contact with a variety of ingredients, if the material wear resistance is insufficient, it is easy to lead to rapid wear of the blade, affecting the processing efficiency and quality.PEEK material has excellent wear resistance, can be in the high load, high speed working environment for a long time to maintain the sharpness and precision of the scraper, greatly extending the service life of the scraper.

Good corrosion resistance

Food processing machinery in the scraper often need to deal with acid, alkali and other corrosive substances, if the material is not good corrosion resistance, it is easy to cause damage to the blade.PEEK material has excellent corrosion resistance, can resist a variety of chemical erosion, to ensure that the scraper in the complex working environment can also work stably.

Superior high temperature stability

In the food processing process, the scraper often need to withstand high temperature environment, PEEK material has excellent high-temperature stability, can maintain the mechanical properties of the material at high temperatures and chemical stability, to avoid deformation or failure of the scraper due to material softening.

Excellent processing performance

PEEK material is easy to process molding, can be made into a variety of complex shapes of the scraper, to meet the needs of different food processing machinery. At the same time, PEEK material also has good dimensional stability, can maintain the precise size and shape in the processing, improve the processing accuracy and stability of the scraper.

Environmental protection and safety

PEEK material is an environmentally friendly polymer materials, non-toxic and harmless, in line with the requirements of food processing machinery on material safety. In addition, PEEK material also has good biocompatibility, can be in contact with food to ensure food safety and hygiene.

Economic benefits

Although the price of PEEK material is relatively high, but because of its long service life, low maintenance costs, processing efficiency and other advantages, in the long run, the use of PEEK material to make scrapers can save a lot of money for the enterprise to improve economic efficiency.

In summary, the choice of food processing machinery PEEK material production scraper has multiple advantages, including excellent wear resistance, good corrosion resistance, superior high temperature stability, excellent processing performance, environmental protection and safety, as well as economic benefits. These advantages make PEEK material become the ideal choice of scraper for food processing machinery, which helps to improve the efficiency and quality of food processing and promote the healthy development of the food industry. With the continuous progress of science and technology and material innovation, the future prospects for the application of PEEK materials in food processing machinery will be more broad.

Case

PEEK scraper can withstand high temperature chocolate processing, not easy to wear and corrosion, and has a long service life.

Scraper is an essential tool in chocolate processing. However, the traditional metal scraper has some problems, such as easy to produce metal chipping, pollution to chocolate, etc. Therefore, the application of PEEK scraper in chocolate processing equipment has become a trend, PEEK scraper is a kind of scraper applied in chocolate processing equipment, which has many advantages.

First of all, it has the characteristics of high temperature resistance, can withstand the use of high temperature environment, will not be deformed or damaged due to high temperature, PEEK scraper can withstand high temperature chocolate processing, not easy to wear and corrosion, has a long service life. Compared with traditional metal scrapers, PEEK scrapers are more durable, which can reduce the maintenance and replacement cost of the equipment to a certain extent.

Secondly, PEEK scraper also has the characteristics of wear and corrosion resistance, even in the case of frequent use and long-term use, the scraper can also maintain its original performance, PEEK material is an environmentally friendly non-toxic material, can be completely in contact with the chocolate, will not pollute the chocolate, the use of PEEK scraper can be better to ensure that the quality of the chocolate and the health and safety, and above all, PEEK scraper in the process of use does not produce any toxicity. Most importantly, PEEK spatulas do not produce metal chips during use, which is very important as metal chips can have a negative impact on the quality of chocolate.

The advantages of the PEEK scraper over conventional metal scrapers, which can become corroded or deformed over time, are obvious and can have a negative impact on the quality of the chocolate. These problems can be avoided with the PEEK scraper because of its high corrosion and temperature resistance, as well as its high strength and environmentally friendly, non-toxic properties, which are not found in traditional metal scrapers.

The use of PEEK scrapers in chocolate processing equipment is a viable option, especially for chocolate processing equipment. With its many advantages, including high temperature resistance, abrasion resistance, corrosion resistance, high strength, and environmental friendliness and non-toxicity, the use of PEEK scrapers avoids the negative effects that metal chips can have on the quality of chocolate, so if you're a chocolate maker or a manufacturer of chocolate processing equipment, a PEEK scraper is an indispensable tool to ensure the quality and hygiene of your chocolates.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.