Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Polyetheretherketone (PEEK) is a semi-crystalline, high performance engineering thermoplastic.

It is a high-temperature wear-resistant material, and its inherent wear resistance and high strength make it ideal for harsh environments.

PEEK has excellent chemical inertness, creep resistance at high temperatures, very low flammability, hydrolysis resistance and radiation resistance.

PEEK also has excellent resistance to steam and hot water and can be operated at temperatures up to 250ºC. It has a continuous operating temperature of 240ºC and a short-term heat resistance of 300ºC, the highest heat resistance among thermoplastic materials. At the same time, PEEK emits virtually no smoke or toxic gases when exposed to flame.

These properties make PEEK the material of choice for aircraft, automotive, semiconductor, marine, nuclear, oil well, electronics, medical, aerospace and chemical processing industries, among others.

For example, PEEK is used in wear and load bearing applications: such as valve seats, pump gears and compressor valve plates, piston rings, fastening hardware, medical implants, sliding assemblies and more.

PEEK can be processed using all traditional plastics manufacturing methods, such as injection molding, extrusion molding, compression molding, etc. It can also be filled with a variety of materials to reinforce the material.

It can also be filled with a variety of materials to enhance its properties.

For example, PEEK is available in unreinforced, 30% glass fiber reinforced, 30% carbon fiber reinforced and HPV reinforced grades.

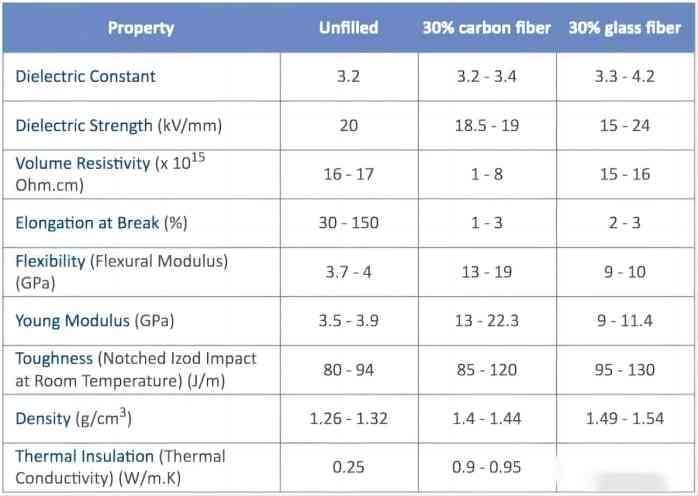

Unfilled, Carbon Fiber Filled, Glass Fiber Filled PEEK Properties Table

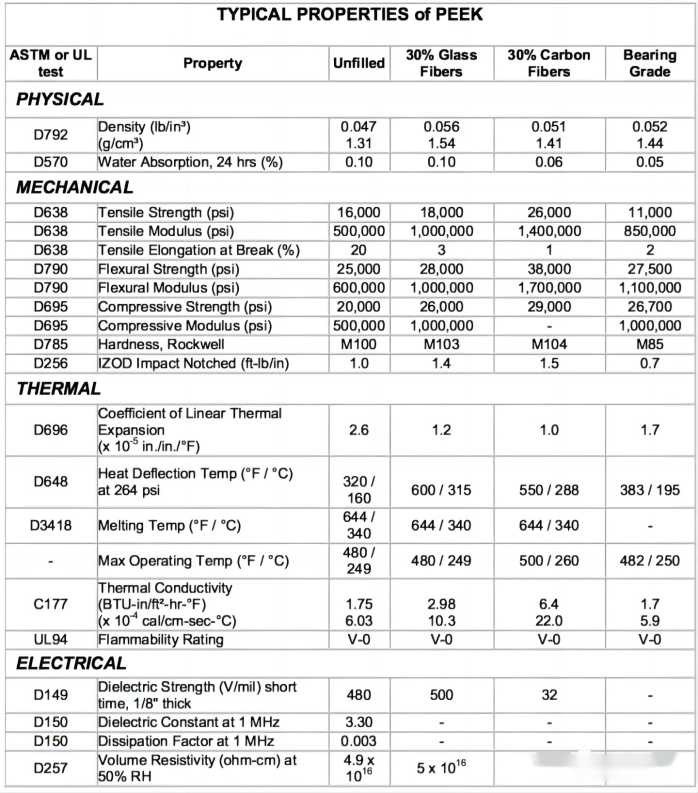

Properties Table for Unfilled, Carbon Fiber Filled, Glass Filled, and Bearing Grades of PEEK

PEEK unfilled: wear and chemical resistant.

Glass fiber filled: higher strength and stiffness.

Carbon fiber reinforced: higher strength and wear resistance.

Bearing grade: Internally lubricated for improved PV limits and wear rates.

Peek-1000

PEEK1000 is an unreinforced general purpose grade with the highest elongation, toughness, and impact strength of any PEEK grade.

PEEK1000 is ideally suited for aesthetically pleasing instrumentation components, as well as sealing components requiring ductility and inertness.

In addition, applications include bushings, connectors, gears, impellers, insulators, pump wear rings, rollers, rotors, seals, thrust washers, valve seats and more.

Peek-CF30 or PEEK, CF30 (CF30 = 30% Carbon Fiber)

CF30 indicates the addition of 30% carbon fiber. The addition of carbon fiber enhances the compressive strength and stiffness as well as creep strength of PEEK.

Carbon fiber reinforced PEEK, exhibits very high mechanical strength while being less dense than 30% glass fiber filled PEEK.

In addition, carbon fiber composites tend to be less abrasive than glass fibers, while offering improved wear and friction properties.

The grade's higher thermal conductivity, which allows for increased heat dissipation from bearing surfaces compared to unreinforced PEEK, is 3.5 times that of unreinforced PEEK, improving bearing life and performance, and also contributing to longer part life in sliding applications.

The addition of carbon fibers also ensures significantly higher thermal conductivity, and carbon-filled PEEK has excellent resistance to hydrolysis in boiling water and superheated steam.

Due to its excellent properties, PEEK-CF30 is used in a wide range of industrial applications such as automotive, marine, nuclear, down-hole oil wells, electronics and aerospace.

PEEK-GF30 (also called Peek-CA30 by some brands)

This 30% glass fiber reinforced type has higher stiffness and creep resistance than PEEK1000 and has better dimensional stability.

PEEK-GF30 is well suited for high static loads at elevated temperatures for extended periods of time. However, it does not slide as well as carbon fiber-reinforced types because the glass fibers tend to wear out the mating surfaces.

PEEK materials offer designers optimum wear resistance and load carrying capacity.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.