Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

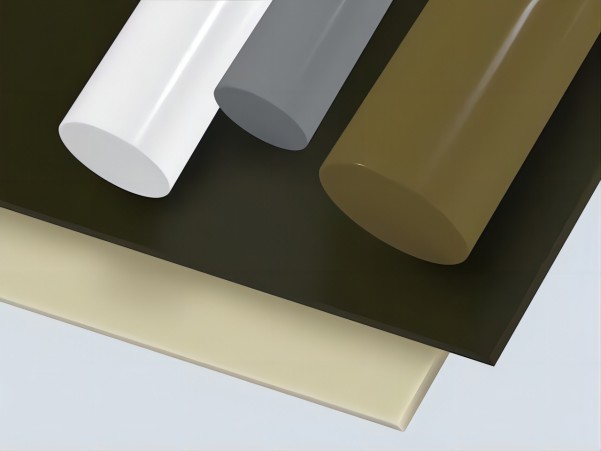

The Semitron® ESd series of electrostatic dissipative products are designed by MCAM-Quadrant for use where discharge is a problem in operation. They are commonly used for sensitive electronic components including: integrated circuits, hard disc drives and circuit boards. Semitron products are also an excellent choice for material handling applications as well as high speed electronic printing and reproduction equipment components.

Unlike many other "dissipative" plastic shapes, Semitron® ESd products are inherently dissipative and electrically stable. They do not rely on atmospheric phenomena for activation, nor do they use surface treatments for dissipation. Static electricity dissipates through these products as easily as it dissipates along a surface. According to Mil-B-81705C, all of these products dissipate 5 KV in less than 2 seconds.

Semitron® ESd 225 Electrostatically Dissipative Acetal

Semitron® ESd 225 is ideal for fixtures used in hard disc drive manufacturing or for handling silicon wafers in the process. It is tan in colour.

Surface resistivity: 10*10 - 10*12 ohms/sq.

Thermal performance up to 225°F (107°C)

Good abrasion resistance

Semitron® ESd 410C Static Dissipative PEI

Semitron® ESd 410c is ideal for handling integrated circuits through the test processor environment. It is black and opaque.

Surface resistivity: 10*4 - 10*6 ohms/sq.

Thermal performance up to 410°F (210°C)

Low stress for tight tolerance processing

High strength and stiffness

Semitron® ESd 420 Electrostatically Dissipative PEI

Semitron® ESd 420 is the only truly dissipative plastic product for high temperature applications.

Surface resistivity: 10*6 - 10*9 ohms/sq.

Thermal Properties

Semitron® ESd 480 Electrostatically Dissipative PEEK

Semitron® ESd 480 is a static dissipative carbon fibre reinforced polyether ether ether ketone for use where the properties of PEEK are required but protection against electrostatic discharge is needed. The material is available in sheet and rod form and is black in colour. Semitron ESd 480 has a surface resistivity of 13 10*6 and 1 X 10*9Ù/sq, but has a heat deflection temperature of 480° F. Its chemical resistance makes it suitable for other structural applications where static dissipation is important in wafer handling and wet process tools.

Semitron® ESd 500HR Static Dissipative PTFE

Semitron® ESd 500HR, reinforced with proprietary synthetic mica, provides the perfect combination of low friction performance and dimensional stability. Semitron® ESd 500HR should be considered wherever teflon* PTFE is used, and is well suited for applications requiring controlled static charge discharge. It is white in colour.

Surface resistivity: 10*10 - 10*12 ohms/sq.

Thermal performance up to 500°F (260°C)

Thermal insulation

Very low coefficient of friction

Extensive chemical resistance

Semitron® ESd 520HR Static Dissipative Process Blanks

Semitron® ESd 520HR offers the industry's first combination of electrostatic dissipative (ESd), high strength and heat resistance. This new ESd material is ideally suited for making inserts, sockets and contacts for test equipment and other equipment handling components. A key feature of 520HR is its unique ability to resist dielectric breakdown at high voltages (>100V). The chart below illustrates the electrical properties of plastic materials commonly used in automated test processors. Even when exposed to moderate voltages, typical carbon fibre reinforced products become irreversibly more conductive.

Only Semitron® ESd 520HR maintains its performance over the entire voltage range while providing the mechanical properties needed to excel in demanding applications.

Surface resistivity: 10*10 - 10*12 ohms/sq.

Semitron MDS100

Semitron® MDS 100 offers an excellent combination of strength, stiffness and stability. It has been developed for use in uncontrolled application environments or where high accuracy is required. It is an ideal choice for semiconductor test sockets, holders and fixtures in test and packaging equipment.

Moisture absorption of 0.10 per cent at 24 hours. (per ASTM D570).

Thermal performance up to 410°F (210°C).

Flexural modulus > 1,400,000 psi

Available from Honyplastic Hongkong stocks.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.