Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

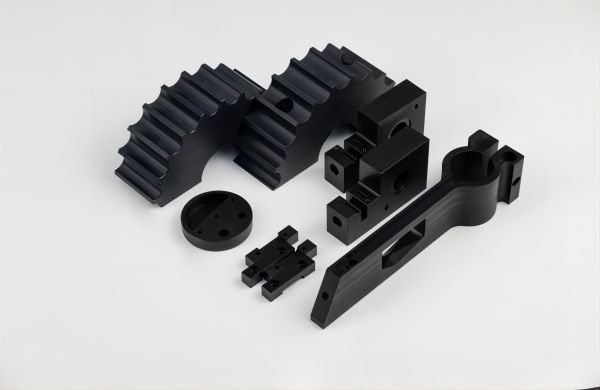

POM is a thermoplastic engineering plastic with excellent mechanical, thermal and chemical stability. It is widely used in automotive, electronic, mechanical and medical applications.The properties of POM include high strength, wear resistance, low coefficient of friction and good electrical properties. It is used in the automotive industry for interior components and transmission systems, in electronics for switches and sockets, in mechanical engineering for gears and bearings, and in medical equipment for surgical instruments and artificial joints.POM's versatility makes it ideal for use in many fields.

What is POM material

POM, known as polyoxymethylene, is a thermoplastic engineering plastic also known as polyoxymethylene, polyoxymethylene, or ultra-high molecular weight Polyethylene glycol methyl ether. It is a polymer made from formaldehyde by polymerization reaction, with excellent physical properties and chemical properties.POM materials are widely used in automotive, electronics, machinery and medical fields.

Properties of POM

1. Mechanical properties: POM has excellent mechanical strength and rigidity, with high modulus of elasticity and high wear resistance. Its tensile strength and impact toughness are at a high level among engineering plastics.

2. Thermal properties: POM has a high heat distortion temperature and can maintain good mechanical properties over a wide temperature range. It has a high melting temperature and can be injection molded and processed.

3. Chemical Stability: POM has good chemical resistance and can resist corrosion of most organic solvents, and has high stability to acids, alkalis, salts and other chemicals.

4. Low coefficient of friction: POM surface has a low coefficient of friction and self-lubrication, making it suitable for the manufacture of high-speed sliding parts.

5. Electrical properties: POM has good insulating properties and low dielectric constant, making it widely used in the electronic field.

Applications of POM

1. Automotive industry: POM material is widely used in automobile manufacturing, mainly applied to automobile interior parts, transmission system, fuel system and seat adjustment device and other parts. Its excellent abrasion resistance and corrosion resistance make it an ideal choice for automotive parts.

2. Electronics: POM materials are widely used in the electronics industry, such as electrical switches, sockets, insulators, electronic connectors and so on. Its good electrical and mechanical properties make it able to meet the requirements of electronic products on material properties.

3. Mechanical engineering: POM materials are widely used in the mechanical field for the manufacture of gears, bearings, sliding bushings and transmission chains and other parts. Its low coefficient of friction and self-lubricating properties enable it to reduce energy loss and frictional wear in mechanical devices.

4. Medical devices: POM materials are widely used in the manufacture of medical devices, such as surgical instruments, syringes, infusion sets and artificial joints. Its chemical stability and biocompatibility make it one of the commonly used materials in the medical field.

Conclusion

POM, as an excellent engineering plastic, has a wide range of applications in several fields. Its excellent mechanical, thermal, chemical stability and electrical properties make it the material of choice in many engineering and technical fields. With the continuous progress of technology, POM materials will play its important role in more areas

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.