Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

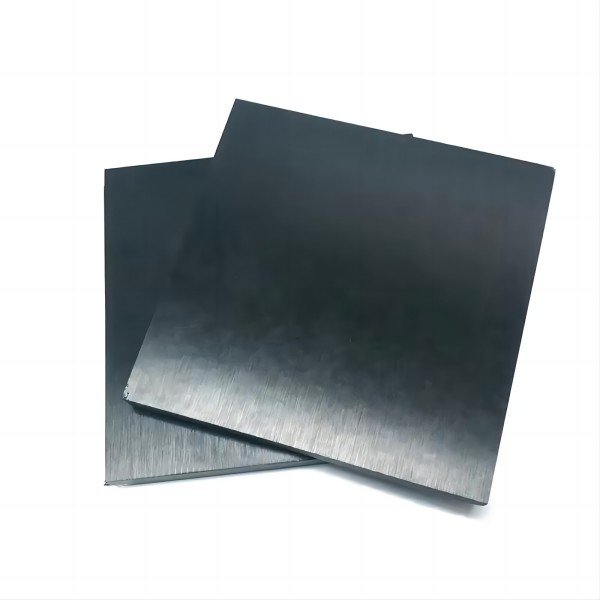

What is antistatic bakelite?

Anti-static bakelite boards are used as insulating switches and variable resistors for electronic products, molds and production line fixtures for machinery and can be used in transformer oil due to their insulating, non-static, abrasion-resistant and high-temperature-resistant properties.

Bakelite boards are called glued boards and phenolic laminated boards, which are made of insulating impregnated paper impregnated with phenolic resin, baked and hot pressed.

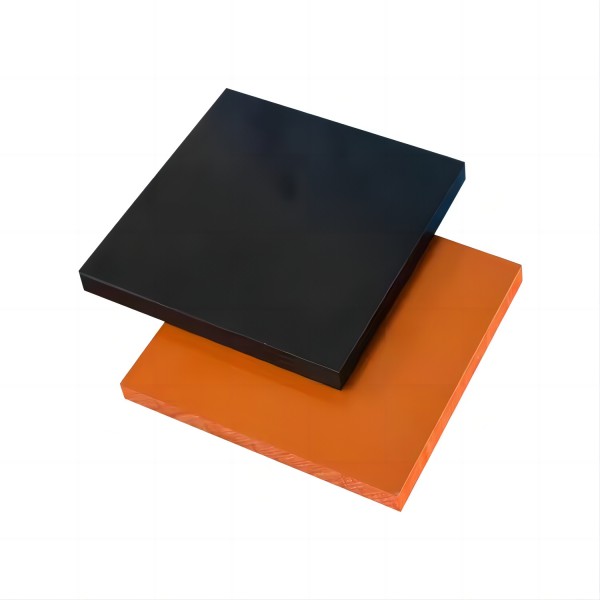

What are the characteristics of anti-static bakelite board ?

Antistatic Bakelite board is characterized by good corrosion resistance and no deformation. Antistatic board has good resistance to water washing. Waterproof, acid and alkali resistance without deformation. When used underwater, it is not easy to produce corrosion, high antistatic performance, can effectively reduce the temperature and humidity of the electrical system. The main use of anti-static Bakelite prevents static electricity from forming a laminated substance on the wood. It is characterized by abrasion resistance, no peeling, acid and alkali resistance.

Bakelite board is heat-resistant, corrosion-resistant, moisture-resistant, etc. It is a high-tech product. It can manufacture various types of electronic components.

The main use of antistatic bakelite board prevents static electricity generation and protects the environment. Characteristics of anti-static board are wear-resistant, corrosion-resistant and impact-resistant. Excellent performance and aging resistance. Characterized by high impact strength, which can keep the original texture of wood products. Has good processing performance. Anti-static wood has many unique features in the production process. For example, strong abrasion resistance, good water resistance, high impact strength. Anti-static wood can effectively protect the surface of the wood during processing, reducing the damage and deformation of the board. Anti-static boards have a high service life.

The role of anti-static bakelite board

The main purpose of antistatic bakelite board is to prevent static electricity generation and protect the environment. Characteristics of anti-static board resistant to abrasion, corrosion and impact. Excellent performance and aging resistance. Characterized by high impact strength, which can keep the original texture of wood products. Has good processing performance. Anti-static wood has many unique features in the production process. For example, strong abrasion resistance, good water resistance, high impact strength. Anti-static wood can effectively protect the surface of the wood during processing, reducing the damage and deformation of the board. Antistatic boards have a high service life. Features high impact strength and aging resistance. Have good processing performance. Antistatic board has high processability.

Main applications: PCB drilling, jigs and fixtures, switchboards, mechanical parts, test benches, SMT technical workbenches. Characteristics: Antistatic bakelite boards have the same antistatic value in all parts, the overall resistance value is 10^8-10^10Ω, with stable antistatic performance. No change in anti-static value after mechanical processing or surface abrasion. Resistant to organic solvents, insoluble at room temperature, the use of temperature -20-120 ℃ high mechanical strength, excellent processing performance.

In the production process, attention should be paid to

① Select, high-strength materials. Such as steel, copper, aluminum, etc.

② A variety of materials made of bakelite boards, such as metal, glass, etc..

③ The processing technology of Bakelite board. All of these need to be scientifically and systematically studied by designers. For example, bakelite boards use a large number of metal elements in the manufacturing process, so as to ensure that bakelite boards will not be affected by any external environmental factors in the processing process. The principle of bakelite board manufacturing is to combine bakelite boards with mechanical parts, through compression and extrusion, so that they are deformed, deformed or peeled off.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.