Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Introduction: PEI film plated metal is a super engineering plastic made of amorphous polyetherimide, which has excellent high temperature resistance and dimensional stability, and also excels in chemical resistance, flame retardancy, electrical properties, high strength and high rigidity. In this article, Advanced Institute of Science and Technology will analyze the superiority of PEI thin film metallization and its innovative applications in the field of high-temperature-resistant materials from multiple dimensions.

High temperature resistance of metalized PEI film

As a high temperature resistant material, PEI film has a unique molecular structure that enables it to maintain dimensional stability at high temperatures and is not easily deformed or melted. For example, PEI film excels in high-temperature environments and can withstand temperatures as high as 200°C with durability

PEI film with metal coating will improve corrosion resistance, electrical conductivity and thermal conductivity.

As a super engineering plastic, PEI film is used in a wide range of applications due to its excellent properties such as high temperature resistance and dimensional stability.

01

PEI + metal plating (corrosion resistant protective layer for high temperature stability)

However, despite the chemical and electrical resistance of PEI itself, the surface may still face the threat of corrosion and oxidation under certain specific environments. In order to enhance the protective performance of PEI materials, people have been exploring and researching to coat metal on the surface of PEI film, which in turn forms a corrosion-resistant protective layer to realize further protection of PEI materials.

02

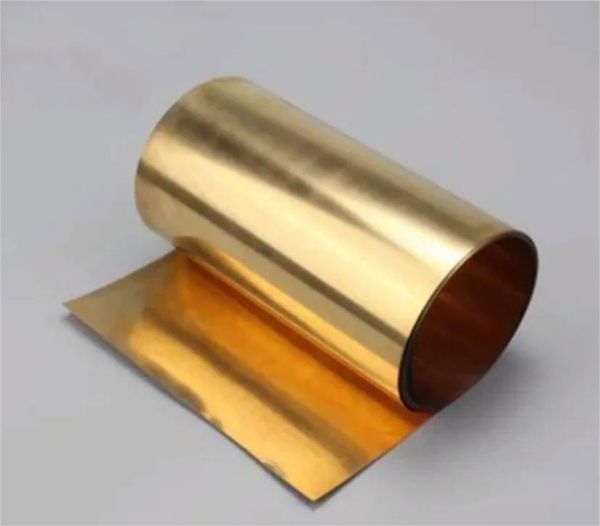

PEI+ Commonly Used Metals

Commonly used metals in the process of metal plating on PEI films include copper, nickel, and silver. These metals can be prepared into thin films by vacuum thermal evaporation, electroplating, magnetron sputtering, etc., and form a coating with strong and uniform adhesion on the PEI surface. The plating of metals not only enhances the chemical and oxidation resistance of PEI materials, but also increases their electrical and thermal conductivity, allowing PEI materials to be used under a wider range of process conditions.

03

PEI Film Metallization Procedure

The process of metalizing PEI film is mainly divided into two steps: substrate treatment and metal plating. Firstly, surface treatment of PEI film is needed to improve the adhesion of metal plating layer. Common methods include surface cleaning, pretreatment, chemical modification and so on. Chemicals that remove impurities and surface contaminants play a key role in the cleaning process, while pretreatment and chemical modification can enhance the chemical bonding with the metal by changing the chemical properties of the PEI surface.

After completing the substrate treatment, the next step is the metal plating process. For different metals, the plating process is different. Taking vacuum thermal evaporation as an example, the metal block is first put into a vacuum chamber, and then heated to evaporate the metal block and form metal vapor. The vapor is deposited on the surface of the PEI film by controlling the pressure, eventually forming a metal plating layer. Electroplating and magnetron sputtering are also commonly used plating processes, which form a metal plating layer by applying an electric current or a magnetic field to the surface of the PEI film so that metal ions or atoms are deposited on the PEI film by electrolysis or sputtering.

04

PEI Metal Coating Excellent Properties

PEI films can obtain a series of superior properties after metal plating. First, the metal coating can improve the corrosion resistance of PEI materials, preventing the surface from being eroded by chemical substances. Secondly, the conductive properties of metal plating can improve the electrical properties of PEI materials, enabling a wider range of applications in electronic devices and other fields. In addition, the thermal conductivity of the metal coating can improve the heat dissipation effect of PEI materials, increase its stability in high temperature environment, so that PEI in aerospace, automotive and other fields of application can be expanded.

05

Multi-dimensional analysis: PEI film metallization application areas

5.1 High-temperature electronic devices in the era of social media

With the popularization of social media, people's demand for high-temperature electronic devices is increasing, and the high-temperature resistance of PEI thin-film plated metal makes it an important part of electronic devices. For example, battery protection film, internal circuit boards and other components in smart phones can be made of PEI thin-film plated metal to improve the high-temperature resistance and stability of the device.

5.2 Innovative applications in the field of medical equipment

Medical devices require a high level of material quality and stability, and PEI thin-film metallization meets these needs. For example, PEI thin-film metalized components in medical devices are able to withstand the rigors of high-temperature sterilization processes, while providing excellent chemical and electrical resistance to ensure the safety and reliability of medical devices.

5.3 High-temperature components in the automotive industry

Automobiles are subjected to high temperatures when traveling, so automotive components need to have good high temperature resistance, PEI thin film metal plating in the automotive industry has great potential for application, such as for the manufacture of lamp reflectors, battery insulation film and engine compartment Insulation Materials, in order to improve the car's high-temperature resistance and safety.

06

To summarize

Overall, metal plating of PEI films is an effective technical means to enhance the performance and application range of PEI materials. Metal plating can increase the corrosion resistance, electrical conductivity and thermal conductivity of PEI materials, thus further improving their application value in various fields. With the continuous progress of technology and in-depth research, PEI film metalizing process and performance there is a lot of room for development, I believe there will be more innovative applications emerge, bringing more possibilities for various industries.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.