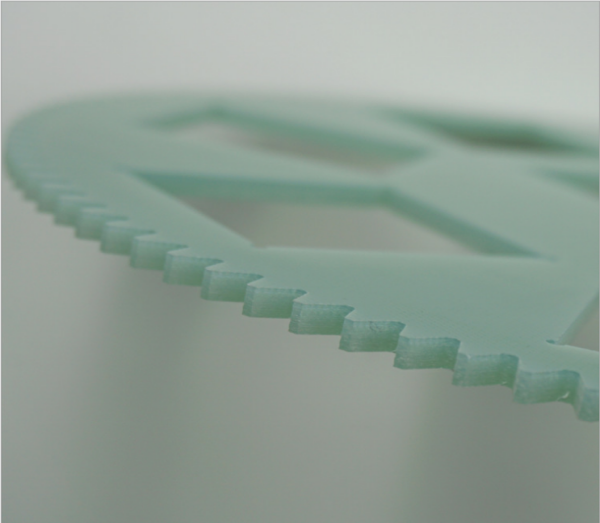

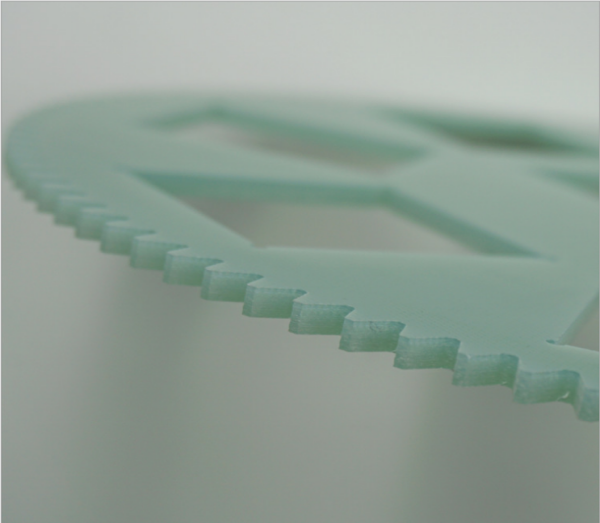

G10 epoxy board, G indicates glass fiber English glass fiber abbreviation, the number 10 indicates that the content of glass fiber in 10%, G10 is synthesized by electronic grade glass fiber cloth and epoxy resin. Flame retardant grade UL94-VO level, can withstand high temperature of 180 degrees, a short period of time can withstand high temperature of 288 degrees, good mechanical properties at high temperatures, with a certain degree of strength, acid and alkali resistance, waterproof and good insulating properties.G10 epoxy board in line with the insulating properties of a certain requirement, high temperature resistance grade of the electrical equipment and so on.

G10 Epoxy Board vs Ordinary Epoxy Board: Performance Comparison and Selection Suggestion

In the field of engineering and manufacturing, choosing the right material is crucial to ensure product quality and performance. As a versatile insulating material, epoxy boards are available in a variety of types, among which G10 epoxy boards are favored for their excellent properties.

G10 epoxy board is a composite material made from laminated epoxy resin and fiberglass cloth, which offers higher mechanical strength and heat resistance than ordinary epoxy board. The heat resistance of this material can usually reach 130°C to 180°C, while that of ordinary epoxy sheets is usually around 100°C.

In terms of comparative performance, G10 epoxy sheet shows significant advantages. Its electrical insulation properties, chemical resistance and humidity resistance are superior to those of ordinary epoxy boards. These properties make G10 epoxy board ideal for use in demanding electronic and electrical applications, such as the manufacture of printed circuit boards (PCBs).

However, regular epoxy board has its own application scenarios. Due to its lower cost, it is often used in applications where temperature resistance and mechanical strength are not required. Plain epoxy board is relatively easy to process and mold and is suitable for some basic insulation and structural support applications.

When choosing between G10 epoxy board or plain epoxy board, the specific requirements of the application need to be considered. If the project requires high heat resistance, excellent electrical insulation or greater mechanical strength, G10 epoxy board is undoubtedly the better choice. Conversely, if cost is a key factor and the application scenario does not require high material performance, plain epoxy board may be more appropriate.

G10 Epoxy Board: Explaining Its Insulation and Stability in High Voltage Environments

In high-voltage electrical applications, the performance of the insulating material is critical, and G10 epoxy board, with its excellent insulating properties and stability, is the ideal choice of insulating material for high-voltage environments. In this article, we will discuss the insulating properties of G10 epoxy board and compare them with ordinary epoxy board.

G10 epoxy board is a composite material made of high-performance epoxy resin and glass fiber cloth laminated together. It possesses excellent electrical insulation properties, including high dielectric strength and low dielectric constant. These properties enable G10 epoxy board to effectively resist current leakage and arcing under high voltage conditions, ensuring the safe operation of electrical systems.

G10 epoxy sheet also offers significant advantages in temperature resistance compared to ordinary epoxy sheets. It maintains stable insulation properties over a higher temperature range and does not deteriorate even under prolonged high-temperature operating conditions. This is particularly important for electrical equipment that needs to operate under extreme temperature conditions.

In addition, G10 epoxy board has higher mechanical strength than ordinary epoxy board, which makes it more durable when subjected to mechanical loads or impacts. This property of G10 epoxy sheet is particularly valuable in support structures and protective components for high voltage electrical equipment.

Although the cost of G10 epoxy board may be higher than some common epoxy boards, its long-term stability and reliability in high-voltage environments can significantly reduce maintenance costs and the risk of potential failures. In the long run, G10 epoxy board is a cost-effective material choice.

In summary, G10 epoxy board's insulating properties and stability in high-voltage environments make it an ideal material for high-voltage electrical applications. Understanding the differences between G10 epoxy board and regular epoxy board will help engineers and purchasers make informed material choices for high voltage projects.

FR4 epoxy sheet differs from G10 epoxy sheet in the following ways:

FR4 epoxy sheets and G10 epoxy sheets differ in the following aspects:

Material Composition:

FR4 usually consists of fiberglass cloth and epoxy resin.

G10 is made of fiberglass cloth and epoxy resin through high temperature and high pressure treatment.

Performance Characteristics:

Moisture Resistance: FR4 performs relatively well in wet environments.

Mechanical Strength: G10 generally has a higher mechanical strength than FR4 and is more resistant to external forces and impacts.

Application Areas:

FR4 is commonly used in general electrical and electronic equipment, such as circuit boards and insulating pads.

Due to its higher strength, G10 is often used in areas that require higher mechanical properties, such as aerospace and high-performance machinery.

Price:

Generally speaking, the price of G10 is relatively higher than FR4.

For example, in common household electronics, FR4 epoxy board may be sufficient for insulation and support needs. However, in some special industrial applications or high-end equipment, G10 epoxy sheet may be preferred to ensure higher reliability and stability.

What is the difference between g10 and g11 in epoxy sheets?

G10 and G11 a kind of glass fiber and resin laminating composite material. g stands for glass fiber (glass fiber), the number refers to the glass fiber content in it.

Comparative analysis of epoxy board G10 and G11

1. Composition comparison

G10 epoxy board composition: imported electronic grade alkali-free glass fiber cloth impregnated with imported epoxy resin, and add the corresponding imported flame retardants, adhesives and other additives, hot pressing and processing.

G11 epoxy board composition: by imported electronic grade alkali-free glass fiber cloth impregnated with imported epoxy resin, and add the corresponding imported flame retardants, adhesives and other additives, by hot pressing and processing of cardboard-like insulating materials.

2.Comparison of performance

Performance of G10 epoxy board: flame retardant grade UL94-VO level, good mechanical properties at high temperature, good processing performance and insulation properties.

Performance of G11 epoxy board: same as G10 epoxy board.

3. Comparison of applications

G10 epoxy board application: motor, electrical equipment for insulation structure, such as circuit breaker, switchgear, transformer, DC motor, AC contactor, explosion-proof electrical appliances and other electrical appliances.

G11 epoxy board application: motor, electrical equipment for insulation structure parts, can be used in humid environment and transformer oil, high-voltage switchgear, high-voltage switches and so on.