Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

"Jig" and "fixture" ? These two words, due to the use of close, so often easy to be confused, or even misuse. Today we will tell you how to distinguish between them.

Jig is mainly used as a tool to assist in controlling the position or movement (or both), focusing on the work and guide the tool;

A fixture focuses on holding the tool in a fixed position. Some devices that serve both functions (controlling and guiding the tool) are also called jigs, but devices that only hold but do not guide the tool are called "fixtures" rather than "jigs".

Definition of fixture: A device used in the process of machine manufacturing to hold a processed object in the correct position for construction or inspection. Also known as fixture.

Jig is a woodworking, ironwork, clamping, mechanical, electrical control and some other crafts of the broad category of tools, mainly as a tool to assist in controlling the position or action (or both).

Fixtures focus on holding a tool in a fixed position.

Some devices that have both functions (controlling and guiding the tool) are also called jigs, but devices that only hold but do not guide the tool are called "fixtures" rather than "jigs".

Broadly speaking, devices used to quickly, easily, and safely mount workpieces at any point in the process are called jigs.

For example, welding fixtures, inspection fixtures, assembly fixtures, machine tool fixtures and so on. Among them, machine tool fixtures are the most common, often referred to as fixtures?

When machining the workpiece on the machine tool, in order to make the surface of the workpiece to achieve the size of the drawings, geometric shape and the mutual positional accuracy of other surfaces and other technical requirements? Before machining the workpiece must be installed (positioning), clamping (clamping). Fixture usually consists of positioning elements (to determine the correct position of the workpiece in the fixture), clamping device? , tool guidance elements (to determine the relative position of the tool and the workpiece or guide the direction of the tool), indexing device (so that the workpiece in a single installation to complete the processing of several workstations, rotary indexing device and linear movement indexing device of two types), connecting elements and clamping specific (fixture base) and other components.

Fixture type according to the use of characteristics can be divided into:

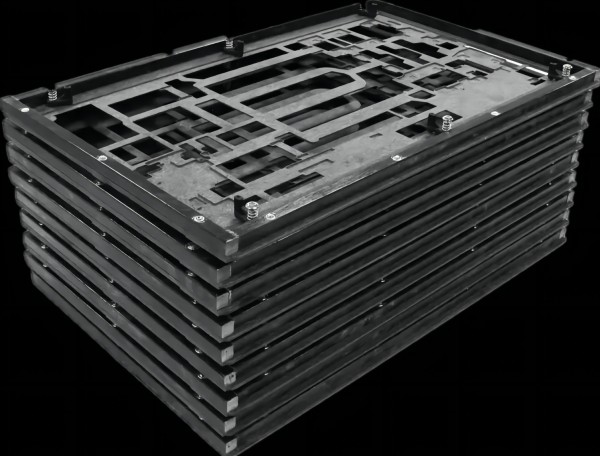

Fixture types, depending on the processing characteristics of the workpiece and different, to the industry's existing fixtures, for example, in the processing machine processing range at the same time clamping a number of workpieces, and will be different types of workpiece clamping and fixing, designed in the same set of fixtures, in the production operation of changing the line as long as some of the parts can be replaced, such as: pressure plate, positioning pins, datum blocks, hydraulic cylinders, and other small parts, in order to achieve the rapid change of the line of the elasticity of the function.

① Universal fixture. Such as machine vises, chucks, suction cups, indexing head and rotary table, etc.

② Specialized fixtures. For a certain product parts in a process of clamping needs to be specially designed and manufactured, the object of the service is specific, targeted very strong, generally designed by the product manufacturer.

③ Adjustable fixture. Can be replaced or adjusted components of the special fixture.

④ Combined fixture. By the different shapes, specifications and uses of standardized components of the fixture, suitable for new product trials and products are often replaced by a single piece, small batch production and temporary tasks.

Although they are close to the use, but not the same, after reading this you will be able to distinguish between the two are not the same, and will not be easily confused in the future, and do not have to use the wrong.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.