Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

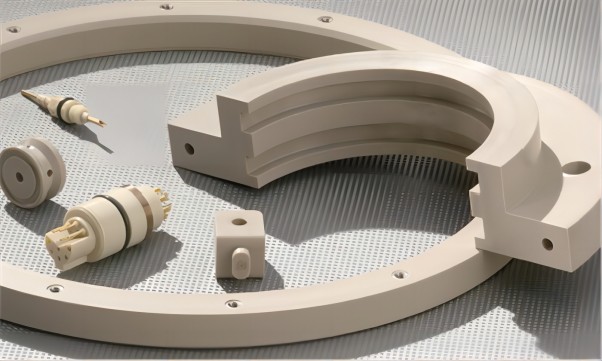

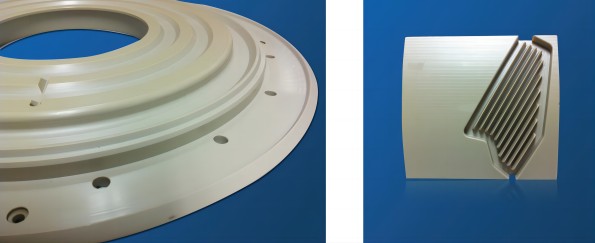

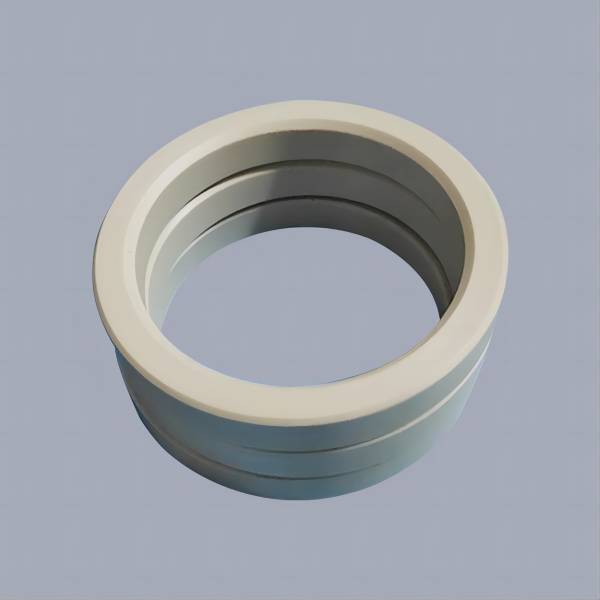

PEEK wear-resistant sealing ring is a sealing ring made of high-performance sealing material. Its advantages include moderate mechanical lightness, stable performance, not easy to swell, small thermal shrinkage effect, easy to process and shape, suitable for mass production, and can maintain precise dimensions. , corrosion-resistant but will not pollute the medium.

PEEK wear-resistant sealing ring is a high-performance plastic sealing ring with many advantages:

1️. Appropriate mechanical lightness: PEEK wear-resistant sealing rings have appropriate mechanical strength and hardness, can maintain stable performance in different media, can withstand certain loads and pressures, and can meet the requirements for sealing rings in the industrial field.

2️. Stable performance: PEEK wear-resistant sealing rings can maintain stable performance under different temperatures and pressures, and can work normally in a wide temperature range. There will be no performance fluctuations due to temperature changes, nor due to environmental changes. Quality problems arise due to changes.

3️. Not easy to swell: PEEK wear-resistant sealing rings are not easy to swell in the medium and can effectively maintain sealing performance without losing the sealing effect due to changes in the medium.

4️. Small thermal shrinkage effect: The thermal shrinkage effect of the PEEK wear-resistant sealing ring is very small, and it can maintain stable performance in high temperature environments without affecting the sealing effect due to thermal expansion.

5️. Easy to process and form: PEEK wear-resistant sealing rings can be mass-produced through injection molding and other processes, and can maintain precise dimensions, meeting the precision requirements for sealing rings in the industrial field.

6️. Corrosion-resistant but will not pollute the medium: PEEK wear-resistant sealing ring has excellent corrosion resistance and can be used in different media, but will not pollute the medium and maintain the purity of the medium.

A variety of industries, PEEK sealing rings offer several advantages:

1. Sealing Reliability: PEEK sealing rings provide reliable sealing performance, preventing liquid and gas leakage, and the flexible design enables the creation of an effective seal even if there is inconsistency in the shaft.

PEEK sealing rings excel in sealing reliability. Due to the characteristics of its polymer material, PEEK sealing rings have excellent elasticity and resilience, able to create effective seals in various shaft inconsistencies. During the sealing process, PEEK sealing rings can adapt to various complex working environments, reduce the impact caused by shaft unevenness or shaft vibration, and effectively prevent the leakage of liquid and gas.

2. Vibration and noise reduction: These sealing rings made of PEEK can also reduce machine noise and vibration, which makes the environment with higher requirements more stable and peaceful, which is extremely important under industrial operating conditions.

Using PEEK sealing rings can significantly reduce machine noise and vibration. This is because PEEK material has excellent shock absorption and buffering properties and can absorb and disperse vibration energy, thereby reducing machine noise. In more demanding environments, such as industrial operating conditions, this stable and calming effect is particularly important, improving work efficiency, reducing machine wear and fatigue, and extending the service life of the machine.

3. Prevent contamination: Excellent resistance is one of the main benefits of PEEK. The ability of PEEK material to limit dust, coolant, chips and other dangerous items from entering the machine and prevent potential damage.

Therefore, the use of PEEK material in these equipment applications may Longer life and better performance.

PEEK material has excellent anti-pollution properties and can effectively limit dust, coolant, chips and other dangerous items from entering the machine. This anti-pollution performance protects the machine from these harmful substances and prevents potential machine damage. At the same time, this anti-pollution performance also enables sealing rings made of PEEK materials to improve the cleanliness and hygiene standards of equipment, and is suitable for food, medical and other industries that require higher hygiene conditions.

4. Good heat resistance: It is well adapted to harsh environments and reduces the stress on equipment components.

PEEK material has good heat resistance and can maintain good mechanical properties in high temperature environments. Therefore, sealing rings made of PEEK materials can adapt to various harsh environments, including extreme environments such as high temperature, low temperature, and high pressure.

This heat resistance reduces stress on equipment components, allowing equipment to operate more stably and reliably. At the same time, it also reduces the risk of equipment damage caused by temperature changes and improves the reliability and service life of the equipment.

Therefore, PEEK wear-resistant sealing ring is a high-performance sealing material with appropriate mechanical lightness, stable performance, not easy to swell, small thermal shrinkage effect, easy to process and shape, suitable for mass production, and can maintain precise dimensions, corrosion-resistant but not It will not pollute the medium and other advantages. It is widely used in various industrial fields and has broad application prospects. It can provide efficient, stable and reliable sealing guarantee for industrial production.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.