FR-4 Product Description:

FR4 is pronounced verbally, but the formal written model number is FR-4.

FR-4 is a flame-resistant material grade code, which means that the resin material must be able to self-extinguish after the combustion state of a material specification, it is not a material name, but a material grade, so the general circuit boards used in the FR-4 grade of material there are many kinds, but most of the so-called four-function (Tera-Function) Epoxy resin plus filler (Filler) and glass fibers to make the composite material.

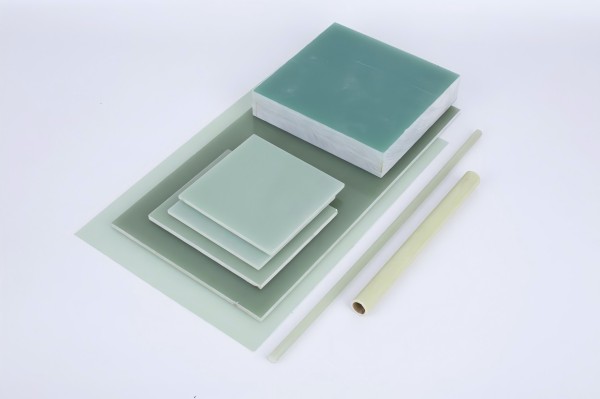

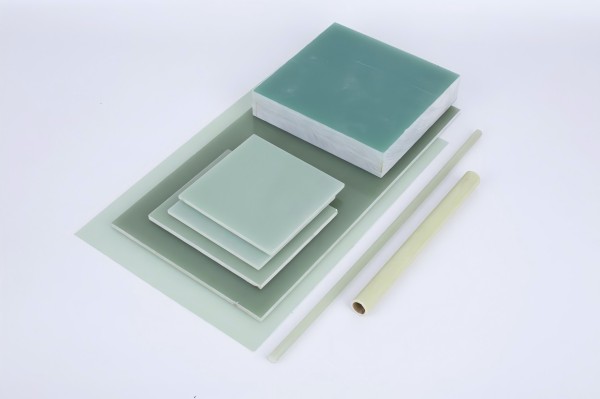

FR-4 Epoxy Glass Cloth Laminate, according to the use of different purposes, the industry is generally known as: FR-4 Epoxy Glass Cloth, insulating board, epoxy board, epoxy resin board, brominated epoxy resin board, FR-4, fiberglass board, glass fiber board, FR-4 reinforcing board, FPC reinforcing board, flexible circuit board reinforcing board, FR-4 epoxy board, flame retardant insulating board, FR-4 laminated board, epoxy board, FR-4 light board, FR-4 glass fiber board, epoxy glass cloth laminate, circuit board drilling pad. 4 laminated board, epoxy board, FR-4 light board, FR-4 glass fiber board, epoxy glass cloth board, epoxy glass cloth laminated board, circuit board drilling pad.

Main technical characteristics and applications: stable electrical insulation properties, good flatness, smooth surface, no pits, thickness tolerance standards, suitable for high-performance electronic insulation requirements of products, such as FPC reinforcement board, PCB drilling pads, fiberglass dielectrics, potentiometers, carbon film printed fiberglass boards, precision vernier gears (wafer milling), precision test panels, electrical (electrical) equipment, insulating spacer, insulating pads, transformer insulation boards, insulation boards, and so on. insulation boards, transformer insulation boards, motor insulation parts, grinding gears, electronic switch insulation boards and so on.

FR4 epoxy glass cloth laminate surface color: yellow FR-4, white FR-4, black FR-4, basket color FR-4 and so on.

FR-4 is a substrate used for PCBs and is a type of sheet material. According to the different reinforcing materials, the boards are categorized into the following four types:

(1) FR-4:Glass cloth substrate

(2) FR-1, FR-2, etc.: paper substrate

(3) CEM series: composite substrate

(4) Special material substrate (ceramic, metal-based, etc.)

FR-4 is a laminated product made of special electronic cloth impregnated with epoxy phenol-formaldehyde resin and other materials at high temperature and high pressure.

Characteristics: High mechanical and dielectric properties, good heat and moisture resistance, and good machinability.

Uses: Insulating structural parts for electric motors and electrical equipment, including various types of switches, FPC reinforcement, electrical insulation, carbon film printed circuit boards, computer drilling pads, mold fixtures, etc. (PCB test frames), and can be used in humid environments and in transformer oil.

FR-4 Performance Characteristics

Vertical laminar bending strength A: normal: E-1/150, 150±5℃≥340Mpa

Parallel laminar impact strength (simple beam method): ≥230KJ/m

Insulation resistance after immersion in water (D-24/23): ≥5.0×108Ω

Vertical layer to the electrical strength (in 90 ± 2 ℃ transformer oil, plate thickness 1mm): ≥ 14.2MV / m

Parallel layer to the breakdown voltage (in 90 ± 2 ℃ transformer oil): ≥ 40KV

Relative dielectric constant (50Hz): ≤5.5

Relative dielectric constant (1MHz): ≤5.5

Dielectric loss factor (50Hz): ≤0.04

Dielectric loss factor (1MHz): ≤0.04

Water absorption (D-24/23, plate thickness 1.6mm): ≤19mg

Density: 1.70-1.90g/cm³; and

Combustibility: FV0

Color: natural

Executive standard: GB/T1303.1-1998

FR-4 process performance:

(1) FR-4 process platen melting point (203℃)

(2) high chemical resistance

(3) low loss factor (Df 0.0025)

(4) Stable and low dielectric constant (Dk 2.35)

(5) Thermoplastic material

FR4 epoxy glass fiber board (epoxy board), the main material for the import of semi-cured sheet, the color has white, yellow, green, room temperature 150 ℃ still have high mechanical strength, dry state, wet state of the electrical properties of the good, flame retardant, used in the electrical, electronic and other industries insulating structural components, the main specifications are 1000 * 2000 mm 1020mm * 1220mm.