Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

In hydraulic machinery, air pumps, and vibration-damping machinery, all moving axes, whether reciprocating or rotating, require some form of guidance to avoid metal-to-metal contact that can cause wear and tear on the equipment. The selection of the correct open rings is particularly important in hydraulic systems, as they isolate the load by pressurizing the sealing box, and in the choice of materials, also taking into account the conditions of use, in the temperature range from -35 ° C to 250 ° C. Not only that, but also excellent resistance to hydrolysis, resistance to steam, and resistance to ultraviolet rays, so that the choice is made of PTFE Polytetrafluoroethylene, PEEK Polyetheretherketone, PI. Torlon-PAI, CNC finishing and injection molding are available.

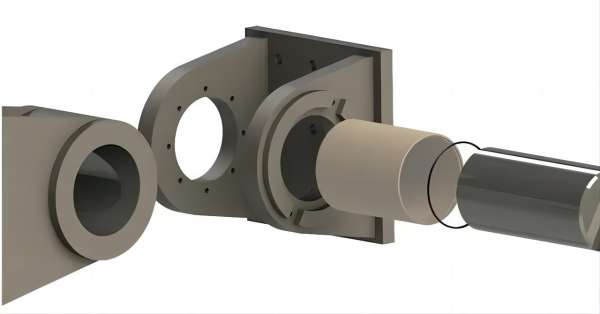

Wear Mechanisms for Split Rings, Guide Rings, and Support Rings

Wear resistance of the support rings in these sealing systems is the key to increasing the overall service life of the components. Wear of seals is mainly categorized into abrasive wear, abrasive wear and lubrication wear. Factors such as friction, pressure, temperature and media also have an impact on the wear resistance of the sealing system.

Material selection and optimization

Support ring according to the shape is also divided into O-ring and open ring, O-ring will fail due to extrusion into the hardware gap, resulting in a bite effect, is the rapid degradation of seals caused by premature failure. And then such a situation, the selection of suitable materials is particularly important, such as PEEK, PTFE, PAI, PI, etc., different materials have different performance and different prices, through different working conditions to choose the right combination of materials in order to get the maximum economic benefits.

Application prospects and outlook

Improving the wear resistance of support rings in sealing systems in hydraulic machinery is an area of continuous development and innovation. With the continuous advancement of materials disciplines and lubrication technology, we can expect more innovative materials to be developed to further doctor the performance of support rings, guide rings, open rings, piston rings, and sealing rings in seals for hydraulic machinery and oil pumps.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.