Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

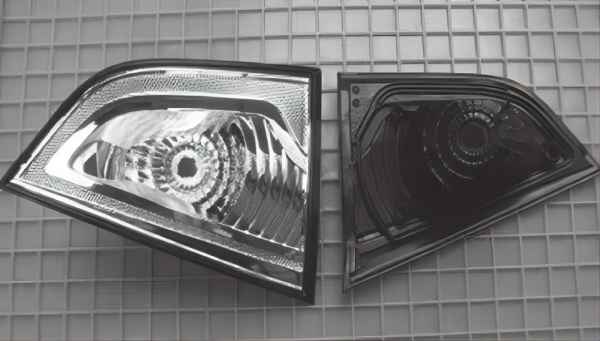

Car lights are indispensable components of the car, related to the car's lighting, signaling, decorative :

The main components of automotive lamps by the reflector, lens, shell, light source, electronic circuit, and installation accessories, etc., the lamp application of plastics are mainly PC , PP , ABS, PMMA and a few other plastic materials. Plastic has a light weight, and corrosion resistance, good impact resistance, high transparency, good insulation, low thermal conductivity, good mechanical properties, plasticity, molding and processing advantages, more and more widely used in various fields.

1.PC (polycarbonate)

PC accounts for about 50% of the plastic materials in headlights, mainly used in headlights and fog lamps, aluminum-plated decorative parts and external light distribution mirror. pc and aluminum-plated layer bonding is very good, can be directly plated on the pc substrate aluminum.

Headlight Why PC?

PC, polycarbonate, has excellent impact properties and transparency, good mechanical properties and electrical insulation properties, a wide range of operating temperatures, high dimensional stability, high creep resistance.

The internal structure of the lamp leads to a certain temperature difference in different parts, and the temperature of some mirrors and trim rings may reach 100-190℃, so PC and PC-HT are generally chosen in the selection of materials.

2.Modified Polypropylene

Lamps in the application of PP is mostly modified PP, in the lamp plastic materials accounted for 30% or so (weight ratio.) Modified PP has strong electrical insulation and chemical corrosion resistance, good fatigue resistance, the highest mechanical properties and heat resistance in general-purpose plastics, compared with other plastics, the price advantage is obvious.

For example, the rear cover of the tail lamp, trim plate and harness guide (PP-T20), headlight housing and rear cover, generally used PP. currently, PP is the main material for headlight housing.

3.PMMA

PMMA, commonly known as acrylic or plexiglass, is a highly transparent amorphous thermoplastic material. Excellent optical properties, transmittance up to 90% -92%, refractive index 1.49, good weather resistance, high surface hardness and excellent overall performance, mainly used as optical transparent products. It is mainly used as optical transparent products. It is also used as light guide material for tail lamp external light guide mirror and interior ambient light. With good mechanical properties, solid and hard at room temperature, light transmittance is greater than 92%, after 10 years of outdoor use only fell to 89%, long time exposure to the outdoors still maintains no deformation, with good weather resistance, high mechanical strength, good machining performance and other good characteristics, and can resist a variety of chemical erosion, mainly used for optical transparent products.

In the field of automobile lamps, it can be used as the light guide material for rear lamp external light distribution mirror and interior ambient light.

4.ABS, PC/ABS alloy

ABS is a terpolymer composed of acrylonitrile, butadiene and styrene.

In the field of automobile lamps, ABS is generally used after modification with PC materials, taking into account the respective advantages of the two materials, the long-term heat-resistant temperature can reach 110 ~ 120 ℃, can also be adjusted according to the use of temperature and impact properties of the proportion of PC in the ABS ABS, PC/ABS alloys are generally used in the rear lamp housing and trim boards.

5. PBT

PBT is commonly known as polybutylene terephthalate, modified PBT mechanical properties are better (glass fiber reinforced PBT accounted for more than 70% of the market), and PA, POM similar to the coefficient of friction is small, self-lubricating, thermal and chemical stability, excellent electrical insulation, high rigidity and hardness, good impact, high dimensional stability, good heat resistance.

PBT is generally used in headlight trim ring, adjustable device in the bracket. PBT and ASA modified and then add fiberglass enhancement can be used to do the fog lamp shell.

6.PET

PET, commonly known as polyester, and PBT collectively known as thermoplastic polyester, or saturated polyester. Lamp decorative ring materials in the past has been mainly heat-resistant PC plastic, in recent years gradually replaced by PBT / PET. PBT / PET lamp materials relative to heat-resistant PC plastic is characterized by high heat resistance, good processing, low cost.

Material processing parts with high surface gloss; excellent processing stability and good hydrolysis resistance; excellent fluidity and heat resistance; material prices and heat-resistant PC compared to significantly reduce the system cost, generally can be reduced by about 40%.

7.Nylon (PA)

PA polyamide commonly known as nylon is a huge class of plastic varieties. Normal screw adjustments or brackets in headlights use glass fiber reinforced nylon 6 or glass fiber reinforced nylon 66.

Aromatic PA is specialty nylon with higher heat temperature and strength than Pa6 or Pa66 and is used for some important adjustment structures and internal brackets in headlights. PA+50%GF material is used for dimming brackets in headlight bodies. PA66 is also used for dimming nuts, mounting nuts and ball nuts in headlight internal parts.

In short, the automobile industry is one of the standards to measure the country's manufacturing industry, the continuous development of engineering plastics for the automobile industry to bring unlimited vitality, just lamps have so many applications.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.