PP material as life is very common plastic materials, with low material costs, very low specific gravity, weldable performance is good, good impact resistance, good bending performance, with transparent or translucent color, and PP material for inorganic strong acids, alkalis, alcohols and other solvents show excellent chemical resistance.

However, PP polypropylene has poor heat resistance, low hardness, low bending strength, poor warping resistance, easy to deform, and poor chemical resistance to heated chlorinated solvents, aromatic solvents, concentrated hydrochloric acid or hydrogen peroxide.

PP polypropylene material by adding carbon black, polymer long-lasting antistatic masterbatch, carbon fiber and other conductive anti-static PP materials are commonly used in the manufacture of semiconductor packaging and shipping containers.

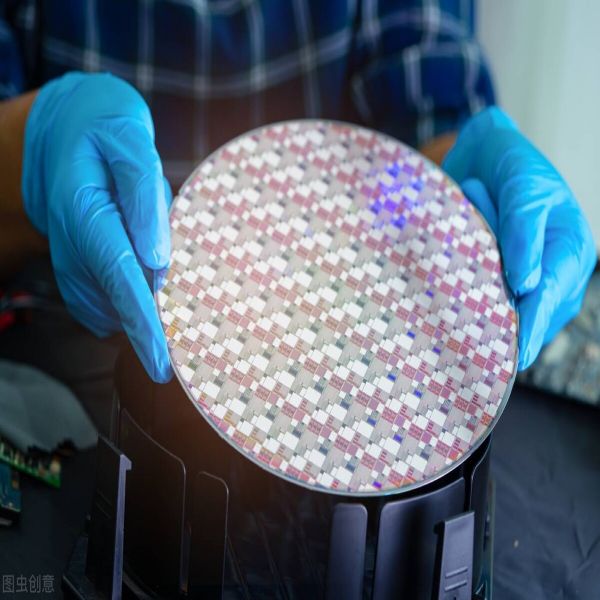

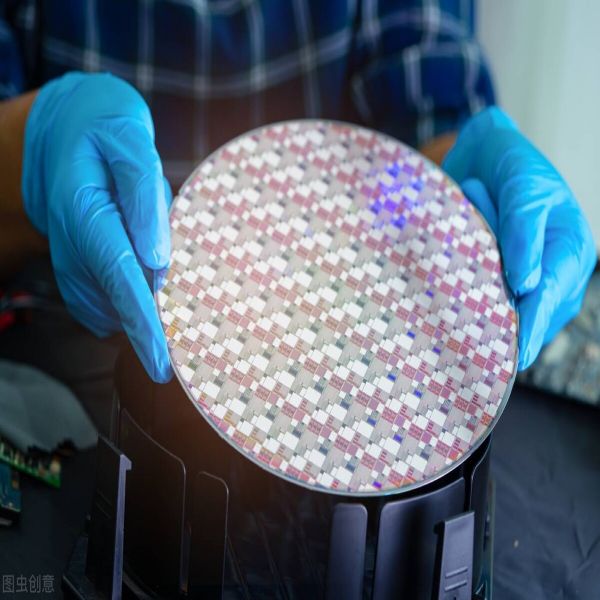

PP black conductive anti-static materials can be used for single piece of horizontally placed wafer box, multiple pieces of horizontally placed wafer box, multiple pieces of horizontally placed wafer canisters, ring isolation ring piece, wafer carrying tray wafer boat, multiple pieces of vertical wafer boat box, photomask shipping box, wafer trays, tray clips, card boxes, tray card strips and so on;

PP natural color transparent anti-static material can be used for single chip horizontal packaging box, multi chip horizontal placement of wafer canisters, multi chip vertical wafer boat box, wafer carrying tray wafer boat, tray clips, clips for process control table, card boxes, tray card strips, etc.;

PP carbon fiber conductive anti-static material can be used for multi-chip vertical wafer boat box trays, etc..

PS polystyrene is divided into GPPS (excellent dimensional stability, good transparency, hard with brittleness) and

HIPS (improved impact strength, good stress resistance, better softness), PS is low cost, good processability, strong resistance to water, weak acids, alkali bases and detergents.

However, PP has lower impact strength even after improved impact, poor heat resistance, and is susceptible to corrosion by most solvents and organics.

By adding carbon black to PS materials, polymer long-lasting antistatic masterbatch, etc. obtained by the conductive antistatic PS materials are commonly used in injection molding or extrusion molding production of semiconductor packaging and transportation containers without heat-resistant requirements.

GPPS transparent antistatic materials can be used for transparent photomask boxes, wafer trays with masks, self-absorption boxes, etc.;

HIPS black conductive anti-static plastic can be used for wafer trays, single wafer packaging blister, extrusion carrier tape, tape reels and so on.

ABS Acrylonitrile Butadiene Styrene Copolymer

ABS is a general-purpose plastic that combines strength, toughness, and impact resistance with natural or transparent colors, high impact strength, and easy color matching. It is resistant to almost all acids, bases, saturated brines and alcohols.

However, ABS is generally heat-resistant and is susceptible to corrosion by organic solvents.

Through the addition of carbon black to ABS materials, polymer long-lasting antistatic masterbatch obtained conductive

antistatic ABS materials are commonly used in the manufacture of semiconductor packaging and transportation containers that do not require high heat resistance.

ABS transparent antistatic material can be used for multi-chip vertical wafer boat box, transparent mask transfer box, transparent mask shipping box, wafer tray with mask, self-absorption box, and so on;

ABS black conductive anti-static plastic can be used for wafer trays, waffle boxes, packaging trays for optical parts, etc.

PC is a hard transparent polymer with high heat resistance, excellent impact resistance and strength, and high transparency, good dimensional stability, not easy to stress deformation, good weathering performance, it is resistant to weak acids, alkali base, oil, alcohol at room temperature.

However, PC material is easy to internal stress cracking, in high temperature will be organic solvents, strong acid and alkali base erosion.

By adding carbon black, carbon nanotubes, polymer long-lasting antistatic masterbatch, carbon fibers and other conductive and antistatic PC materials obtained through the addition of PC materials are commonly used in the manufacture of semiconductor packaging and shipping containers with certain heat-resistant requirements.

PC ordinary transparent plastic can be used for transparent multi-piece vertical crystal boat box, transparent photomask transmission box;

PC black conductive anti-static plastic can be used for wafer carrying tray wafer boat, multi-chip vertical wafer boat box, photomask shipping box, wafer tray, self-absorption box, etc.;

PC carbon fiber conductive anti-static plastic can be used for wafer isolation ring, multi-chip vertical wafer boat box, etc..

PBT Polybutylene Terephthalate

PBT has good heat resistance and low water absorption.

However, PBT is not resistant to strong acids and alkalis, and is resistant to organic solvents.

PBT natural color anti-static plastic can be used for wafer carrying tray wafer boat, multi-chip vertical wafer boat box, and so on.

PPO Polyphenylene Ether

Pure PPO is generally white or light yellow powder, poor melt fluidity, prone to stress cracking, low notched impact strength, unable to injection molding. Through and PS and other materials composite improvement to improve the fluidity of the material, can be injection molding, the current general is MPPO, that is, PPO + PS. MPPO has a low water absorption, low specific gravity, good dimensional stability, and has good heat resistance.

However, the low percentage of PS in the heat-resistant grade MPPO drastically reduces its fluidity.

The conductive and anti-static PPE materials obtained by adding carbon black, carbon nanotubes, carbon fibers, etc. to MPPO materials are commonly used in the manufacture of semiconductor packaging and shipping containers with certain heat-resistant requirements and high dimensional stability requirements.

PPO carbon black / carbon fiber conductive anti-static plastic is mainly used in the production process of a variety of high-temperature trays that need to be cleaned and baked.

PA Polyamide Nylon

Nylon PA has good toughness and excellent heat resistance, and has good mechanical strength.

However, the nylon material is easily deformed and warped after absorbing moisture, which cannot meet the requirements of semiconductor carrier precision.

By adding glass fiber and long-lasting antistatic masterbatch to the PA material can be color-matched antistatic PA material is commonly used in the manufacture of certain heat resistance requirements, toughness and can be adjusted to the color of the semiconductor carrier accessories, such as color-coded color visual management of the tray with the card strips, the state of the identification of the card slots, a variety of handles and so on.

PPS polyphenylene sulfide material is hard and brittle, with very good rigidity, excellent heat resistance, long-term workload and thermal load can maintain high mechanical properties and dimensional stability, excellent chemical resistance.

However, PPS has high specific gravity and relatively high cost.

By adding carbon nanotubes to the PPS material, carbon fibers and other conductive anti-static PPS materials are commonly used in the manufacture of high and low temperature requirements, corrosion-resistant process used in the semiconductor packaging and shipping containers and equipment parts.

PPS black conductive anti-static plastic is mainly used in the production process of a variety of high and low temperature resistance, chemical cleaning semiconductor trays and semiconductor automated production line of anti-static conductive mechanical parts.

PEI Polyetherimide

PEI materials have excellent strength-to-weight ratios, high impact strength, good heat resistance, and resistance to high-temperature steam, and good resistance to a wide range of chemicals.

The conductive and antistatic PEI materials obtained by adding carbon nanotubes and carbon fibers to PEI materials are commonly used in the manufacture of semiconductor packaging and shipping containers as well as equipment parts used in processes requiring high and low temperatures and corrosion resistance.

PEI amber transparent mainly used in the production process of a variety of high and low temperature resistance, chemical cleaning resistance of the wafer carrying tray wafer boat, multi-piece vertical wafer boat box.

PEI black conductive and anti-static plastic is used for the production of wafer carrier tray wafer boat, multi-chip vertical wafer boat box, semiconductor tray, semiconductor automated production line of anti-static conductive mechanical parts.

PEEK polyether ether ether ketone mechanical properties, heat resistance, abrasion resistance and chemical resistance are outstanding, and has superior dimensional stability and flame retardant properties. What limits the use of PEEK is the cost.

Because of PEEK ultra-high comprehensive characteristics, so by adding carbon nanotubes to the PEEK material, carbon fibers and other conductive antistatic PEEK material is commonly used in the manufacture of high and low temperature requirements, corrosion-resistant process used in the semiconductor fixtures and tools.

PEEK black conductive anti-static plastic is mainly used in the production of semiconductor automated production line wafer carrying tray wafer boat, wafer pickup, adsorber, etc..

Fluoroplastic PFA PVDF

Fluoroplastics have unparalleled chemical resistance, able to withstand strong acids and alkalis in the semiconductor process, and have a high degree of crystallinity and excellent heat resistance.

Fluoroplastics PFA and PVDF are mainly used in the production of wafer carrying trays and wafer boats in semiconductor automated production lines.