Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

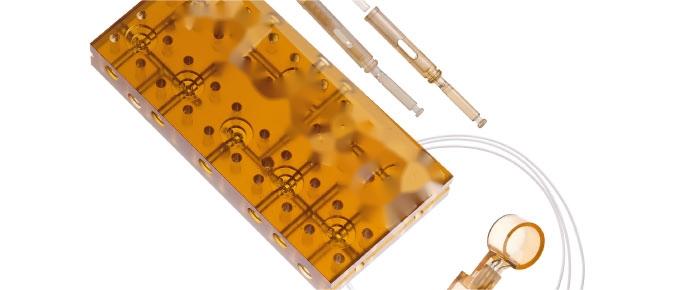

Benefit of Polyphenylsulphone (PPSU) Manifold

If you are producing medical, research or life science equipment, you must be familiar with PPSU material. As a kind of thermoplastic special engineering plastic, it has extremely high temperature resistance, corrosion resistance and high transparency. Among them, the manifold of PPSU material is the most commonly used. The bonded manifolds of PPSU material have the unique ability to meet the precise requirements of healthcare and life sciences, providing control of gases and chemicals. Additionally, you can build many system components into the manifold, such as pumps, flow sensors, valves, and connectors.

Benefits of PPSU Material Plastic Manifolds

1) Good chemical resistance to acids, alkalis, greases and solvents, hydrogen peroxide and hot steam of some plastics

2) Minimal exhaust volume under vacuum to help maintain a sterile environment

3) Good plasma resistance

4) Reduce overall footprint and weight

5) Integrate multiple components including fittings, pressure regulators, valves, restrictors and filters

6) Integrate complex pneumatic and/or fluid circuits directly into the manifold

7) Maintain precise fluid volumes between different components

8) Eliminate potential dead ends in fluid pathways

9) Improve reliability and operational efficiency

10) Reduce overall cost

Application

Life science application

PPSU material manifolds have the unique ability to meet the precise requirements of life science applications. Cell counters, IVD instruments, and gene sequencers are particularly well suited for plastic manifolds. In addition, materials such as polyether ether ketone and polyphenylene sulfone PPSU have qualities that make life science projects successful, including optical clarity, chemical resistance and low fluorescence.

Medical application

Multi-layer PPSU material manifolds have become the perfect answer for those looking for smaller, more portable and lower maintenance medical devices. They provide precise control and smaller packaging for gas and liquid management. Therefore, PPSU material manifolds are commonly used in laboratory accessories, patient monitoring equipment, diagnostic instruments, surgical machinery, blood analyzers, feminine health instruments, orthopedic tools, dental drills, and many more applications

Instrument application

Instruments designed for scientific research and medical diagnostic testing rely on the specialty engineering plastic PPSU machined parts and manifolds to perform to consistently high standards. PPSU material is the best practice method for controlling many research process chemicals due to the reactivity of metals. can interfere with test results, PPSU material is especially useful for visualizing air bubble detection, optical inspection, and light-modulated flow paths.

Research application

Performing scientific experiments in the most cost-effective manner requires precise and reliable plastic machined parts and manifolds. Unfortunately, research often requires the use of expensive materials, including reagents and other working fluids. Still, the researchers were able to minimize the amount of fluid used by the device using bonded plastic manifolds and plastic mechanical parts. Many people use manifolds for a variety of purposes, including DNA sequencing, environmental testing equipment, diagnostic instrumentation, and food quality control testing.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.