Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

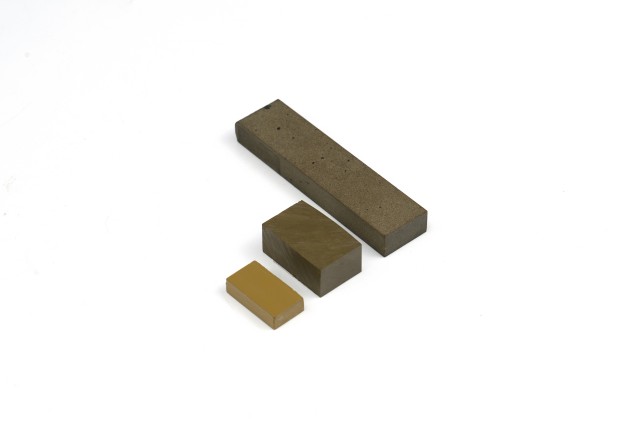

Polyimide (PAI) - steel warrior at very high temperatures, all-around champion at low temperatures_Advantages of industrial manufacturing appication:

Polyimide, or PAI for short, is an engineering polymer par excellence. It defies the rigors of extreme temperatures and exhibits unmatched strength and stability. At lower temperatures, PAI's durability, impact resistance and chemical resistance are also exemplary, making it an all-around, high-performance polymer choice.

In the PAI family of materials, this polymer, with enhanced mechanical properties, reliably demonstrates excellent service performance in environments up to 500°F. This makes it a leader in the manufacture of engineered thermoplastic semiconductors as well as chemical processing equipment.With a glass transition temperature (TG) of 537°F (280°C), PAI far exceeds its maximum operating temperature, demonstrating excellent heat resistance and dimensional stability.

Compared to most other molded plastics, PAI has superior strength and stiffness. Its abrasion, impact and chemical resistance are exceptional in environments subjected to high loads and speeds. In particular, PAI excels in the presence of industrial gases, hydrocarbons, automotive and aircraft fuels, as well as fluids and lubricants, making it ideal for automotive and aircraft component manufacturing. PAI is also suitable for a wide range of industrial and manufacturing applications, performing in harsh thermal, chemical and high wear conditions.

PAI's performance benefits - an example of quality engineering plastics:

1. Exhibit exceptional strength, stiffness and stability over a wide temperature range.

2. Provide maximized performance and reliability for high-temperature applications.

3. Have unique impact resistance and abrasion resistance.

4. Combines high tensile strength and elasticity with high compressive strength.

5. Outstandingly low coefficient of thermal expansion coupled with high thermal deflection temperatures make PAI the preferred choice for a wide range of industrial manufacturing applications as well as products requiring high temperature performance up to 500 degrees Fahrenheit.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.