Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

What is the difference between the characteristics of the three models of epoxy sheet?

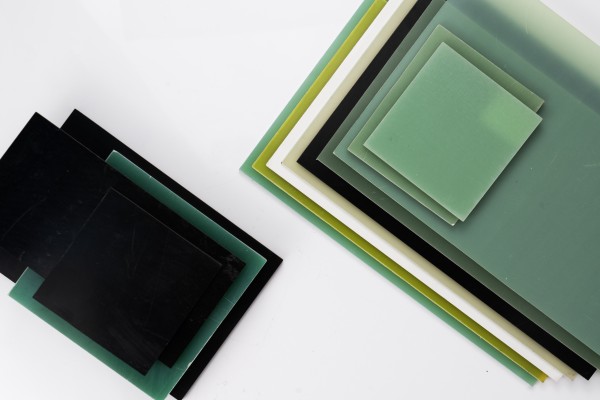

What is the difference between the characteristics of the three models of epoxy sheet? Divided into 3240 epoxy plate, FR4 epoxy plate, G11 epoxy plate three large models, I give you an introduction, the main content is as follows:

1, 3240 epoxy plate features

It is made of fiberglass cloth impregnated with epoxy resin, dried and hot pressed. Its board surface is free of bubbles, pockmarks and wrinkles. It is characterized by excellent mechanical function, excellent mechanical function, arc resistance, and a variety of specifications.

For example, it can perform good mechanical function under medium temperature; under high temperature environment, it can better perform its electrical property.

Therefore, due to these characteristics, epoxy sheet is well suited for highly insulating structural components in the electrical and electronic fields.

However, it is processed with materials that contain halogens. The halogen elements mentioned here are fluorine, chlorine, bromine, iodine and a, which act as flame retardants but are toxic. When burned, they emit dioxins, benzofurans and other harmful gases, and have a thick smoke and odor that can easily cause cancer and damage. As a result, the use of halogen-free epoxy boards is now advocated.

Therefore its information is not very environmentally friendly and has some damage to the environment and human body, especially when burning it will produce a lot of smoke. It does not meet the environmental requirements set by the state, but the price is relatively cheap.

2, FR4 epoxy board function

FR4 is usually water green color. It is a sheet-like laminated product made of special e-cloth hot dipped at high temperature and pressure and impregnated with epoxy resin and other materials.

Compared with 3240, it has many advantages, such as high temperature resistance (Class B), insulation, dielectric, flame retardant (meets 94V-0 specification), moisture resistance, good resistance, smooth surface, no pits, thickness, and public service specification. Suitable for high performance electronic insulation products.

Even today's high speed trains and bullet trains use this insulation data. It can be simply understood that FR4 is an upgraded version of 3240.

3, G11 epoxy board function

G11 epoxy board is one of the three epoxy boards with better functions.

G11 epoxy board is one of the epoxy boards with higher thermal stresses up to 288°C. Its heat resistance value is as high as 160-180 degrees Celsius, especially its water absorption rate is very low (water absorption rate is almost 0; water absorption rate after 24 hours of immersion is only 0.09%).

G11 epoxy board is the best choice for high-voltage switchgear, high-end appliances and electronics. But the price is naturally higher than the first two types.

G11 epoxy sheet has high mechanical and dielectric function, good heat and moisture resistance and good processability. Used for plastic molds, injection molds, machine building, molding machines, drilling machines, injection molding machines, motors, pcb.ict fixtures, bench grinding pads.

Difference between FR4 and 3240 epoxy sheet?

1. FR4 material belongs to fiberglass, 3240 material belongs to epoxy resin. And fr4 temperature resistance, performance is better than 3240, fr4 general conventional color is aqua green, 3240 conventional color is yellow.

2. FR4 epoxy plate color is very natural, a little jade feeling, and 3240 epoxy plate color a little wink.

3. FR4 is the improvement of 3240 epoxy board, the flame retardant property of FR4 epoxy board meets the national UL94V-0 standard. 3240 epoxy board has no flame retardant property.

4. FR4 can have the function of natural extinguishing in case of fire.

5. FR4 dimensional stability is better than 3240, and the pressing process, FR4 thickness tolerance control is also much better than 3240, more suitable for processing.

6. 3240 epoxy board is halogenated, for the environment, the human body is not very environmentally friendly. Also does not meet the national green sustainable development strategy. FR4 epoxy board is just the opposite.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.