Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

First, from the material is slightly different: 3240 is with epoxy resin and FR-4 with epoxy phenolic resin, they are contained and contained relationship.

The distinction between 3240 and FR-4 epoxy plate

Second, the name of the difference, the specific meaning of different representatives.

1, 3240 full name epoxy laminated glass cloth board, which * number 3 on behalf of the laminated products, winding products, vacuum pressure impregnated products. 2 on behalf of the inorganic bottom talent laminate. 4 on behalf of the temperature index level 155 degrees, 0 on behalf of the product varieties code.

2, FR-4 is a flame-resistant material grade code, which means that the resin material must be able to self-extinguish after combustion state of a material specification.

3, Different flame retardant: FR-4 is better than 3240 flame retardant, is an improvement of 3240.

4, Different environmental protection: FR-4 is halogen-free, 3240 is halogenated, there will be dust when processing, so FR-4 relative to 3240 more environmentally friendly, but 3240 is cheaper, for the requirements are not very high equipment, or can be used.

The difference between FR4 and 3240 epoxy sheet is as follows:

* Material: FR4 (fiberglass), 3240 (epoxy resin).

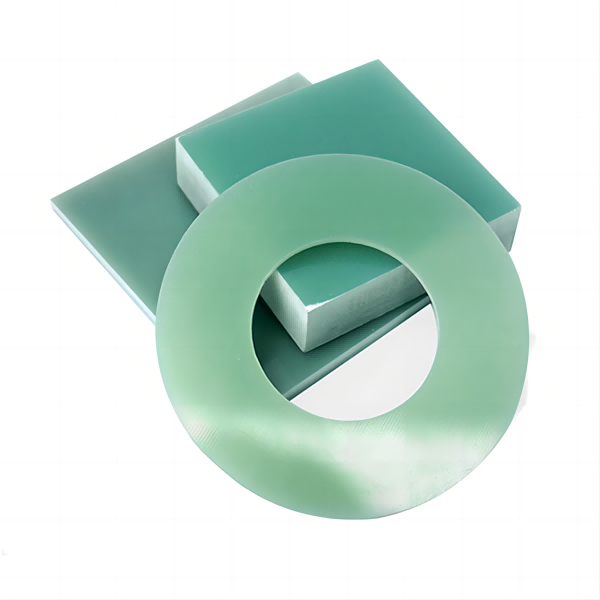

* Color: FR4 (aqua green), 3240 (yellow).

* Flame retardant: FR4 (yes), 3240 (no).

* Environmental friendliness: FR4 (no radiation, environmentally friendly), 3240 (halogenated, environmental and human hazards).

* Dimensional stability: FR4 (better than 3240).

* Temperature resistance: FR4 (better than 3240).

* Price: FR4 (more expensive than 3240).

Both are epoxy boards, also known as insulating boards, is a widely used in electronic products in the insulating material, in the actual application scenario, you can choose the right insulating board according to the demand and price.

The commonly used epoxy laminates on the market are 3240 and FR-4 epoxy laminates, so what is the difference between them? What are the advantages of FR4 epoxy laminate?

Difference 1 : FR4 has good flame retardant properties.

FR4 is an improved product of 3240 epoxy laminate, FR-4 epoxy laminate flame retardant performance in line with national UL 94V-0 standards. 3240 epoxy laminate has no flame retardant properties.

Difference 2 : the color is transparent and bright.

The color of FR4 is very natural, a little like emerald, while the color of 3240 epoxy laminate is a little flash, does not look very natural, most of the color is not very uniform.

Difference 3 : FR4 is radiation-free and environmentally friendly.

3240 epoxy laminate contains halogens, less environmentally friendly to the environment and the human body. It is also not in line with the national green sustainable development strategy. FR-4 epoxy resin sheet is just the opposite.

Difference 4: FR4 has good dimensional stability.

The dimensional stability of FR4 is better than 3240, and in the pressing process, the thickness tolerance of FR4 is controlled much better than 3240, which is more suitable for processing.

Difference 5: FR4 can be self-extinguishing in a fire.

FR4 can be naturally extinguished in the event of fire.

Difference 6 : low water absorption.

Its water absorption rate (D-24/23, plate thickness 1.6mm): ≤ 19mg, for its use in wet transformers and other equipment provides a good help.

Due to the good performance of FR-4 epoxy laminate, it is now the material for insulating parts in the high-end electrical and electronic industry. Of course, 3240 epoxy laminate still has a certain market due to the price advantage.

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.