Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PEEK material related products

No.01, New Energy Vehicle Flat Wire Motor PEEK Flat Wire

New energy electric vehicles are driven by electricity, and the safety of electricity is particularly important. Choosing excellent materials is the key to ensure the safety of new energy vehicles.

PEEK (polyether ether ketone) materials can be said to be the "hexagonal warrior" in the field of special engineering materials, because it has a variety of excellent performance, such as corrosion resistance, wear resistance, high strength, low density and other characteristics.

Particularly suitable for the manufacture of durable and important parts, can extend the service life of the parts, reduce the frequency of maintenance, and reduce costs.PEEK in the new energy electric vehicle construction and bearing and gear parts in the field of increasing popularity, part of the place gradually replaced by aluminum, titanium, steel and other traditional metal materials.

PEEK corona resistance, low dielectric constant, with bending resistance and chemical resistance (including lubricants, ATF oil, impregnated paint, epoxy resin paint), resistance to high and low temperature conditions, is one of the preferred new energy vehicle motor.

No.02, Medical implantable PEEK materials

As the name suggests, PEEK materials that can be used in the preparation of "implantable devices" are called implantable grade PEEK, which are commonly used in orthopedic implantable consumables (e.g., intervertebral fusion devices, ligament repair anchors, and articular interface screws), neurosurgical repairs (e.g., artificial cranial bones, maxillofacial bones), and cardiovascular products (e.g., cardiac valves, pacemaker housings, etc.). cardiovascular products (such as heart valves, pacemaker shells, etc.).

In recent years, some manufacturers are using modified PEEK materials for oral implants, trauma bone plates and other products with high mechanical properties. Implant-grade PEEK in addition to meet the biological safety of ordinary medical grade PEEK, should also have more stringent biocompatibility requirements, such as systemic toxicity, genotoxicity, carcinogenicity, blood compatibility and implantation reaction, etc., but also need to comply with the "YY/T 0660 Surgical Implants with polyether ether ketone (PEEK) polymer standards and specifications" requirements.

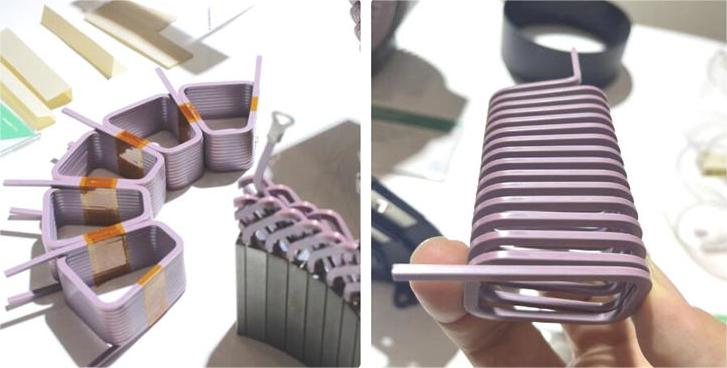

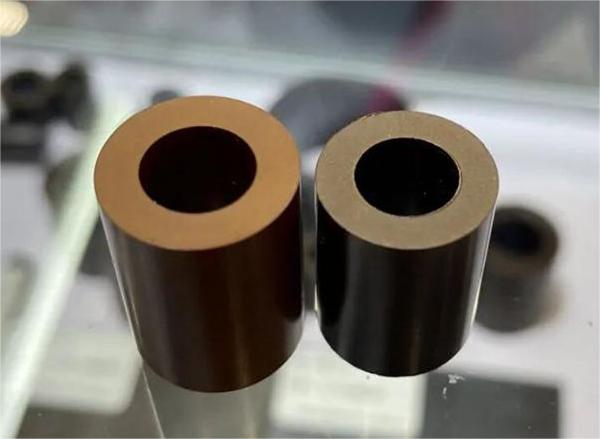

No.03, PEEK Motor Rotor Reinforcement Bushings

Advantages:

1, lightweight, ultra-high strength to help achieve design lightweight;

2, Resistant to chemical medium environment inside the motor;

3, excellent fatigue resistance characteristics.

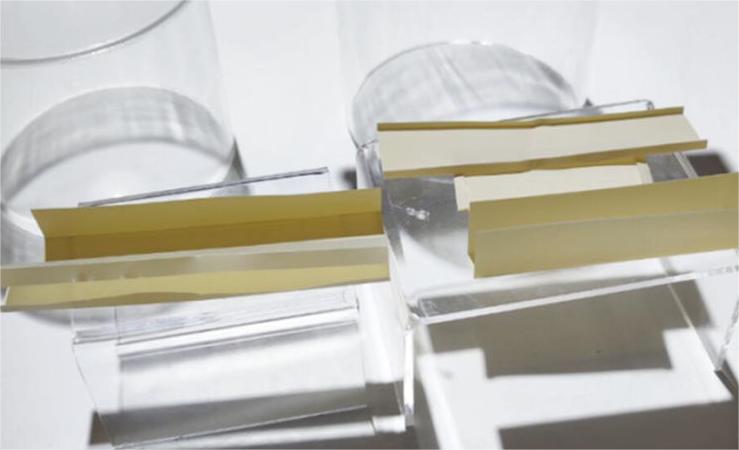

No.04, PEEK film

PEEK film has high heat resistance, good electrical properties and mechanical properties, continuous use temperature up to 240 ℃, dielectric loss as low as 0.001 ~ 0.003, light transmission rate of up to 85.9%. In particular, its chemical resistance, hydrolysis resistance, radiation resistance and other properties, even in the high-performance film is also quite prominent.

PEEK film application areas:

1.Speakers for cell phones and vibration film for consumer speakers;

2.High-performance gaskets and spacers for high-speed micro-motors for cell phones and automotive parts.

3, 5G antenna substrate and filters, connectors and other related components

4, supercapacitors, dielectrics for printing templates and insulating layers for electric vehicle batteries.

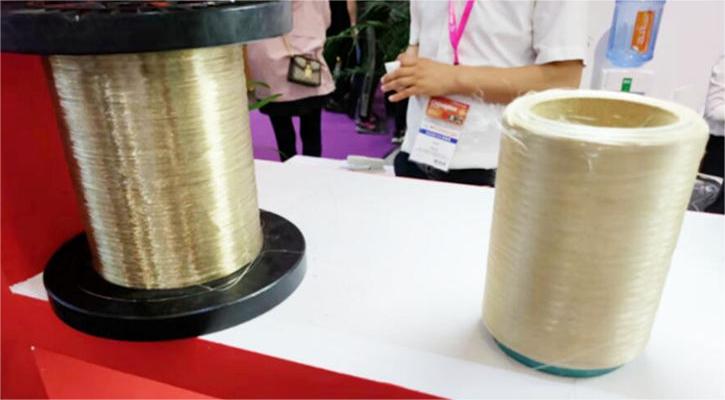

No.5.PEEK prepregs

Mixed knitting molding is the traditional molding technology for continuous CF/PEEK prepregs, where PEEK resin is first processed into fibers, which are then mixed with carbon fibers to form fabrics in hollow, strip, tape, three-dimensional or two-dimensional geometrical shapes, and then impregnated with fibers by melting PEEK through hot pressing. The advantages of the hybrid molding technology is easy to control the glue content, you can get uniform fiber impregnation, high dimensional stability and complex shape of the material products.

No.06, CF/PEEK composite sheet (CCM method)

CCM method of continuous molding, high and stable production efficiency, can also continuously produce shaped parts, advanced technology.

No.07.CF/PEEK compound thick plate

Continuous Carbon Fiber CF/PEEK thermoplastic composite sheet has the properties of small specific gravity, high temperature resistance, humidity and heat resistance, impact resistance, good dimensional stability, high fatigue strength, X-ray transmittance, and biocompatibility, which is one of the choices to replace metal materials in the medical field, aerospace and military industry.

No.08, CNT modified PEEK

Carbon nanometer new material: semiconductor conductive Antistatic Material, internal sulfur-free, no precipitation, molding without decarburization high clean, finished product surface low reflective, with stable conductive properties, low density, recycling and other advantageous properties.

No.09.Zeolite membrane dehydration technology

Creative product development through low temperature, low pressure dehydration technology manufacturing separation of pharmaceutical components: improve the efficiency of the esterification reaction, improve the conversion rate of the reaction, product yield, reduce the amount of raw materials used.

No.10, PEEK stator, rotor insulation groove liner, insulation groove wedge

PEEK has voltage resistance, low thermal conductivity, temperature resistance, resistance to ATF oil, and resistance to bending stress in molding process.

No.11.PEEK Fine Filament

PEEK filaments / monofilaments through continuous extrusion process molding, can be continuously extruded thousands of meters without breaking, tolerance ± 0.03mm, with high toughness, high strength, corrosion resistance, good dimensional stability and other excellent properties, widely used in analytical instruments, petrochemicals, medical equipment, aerospace, paper machinery and other indus

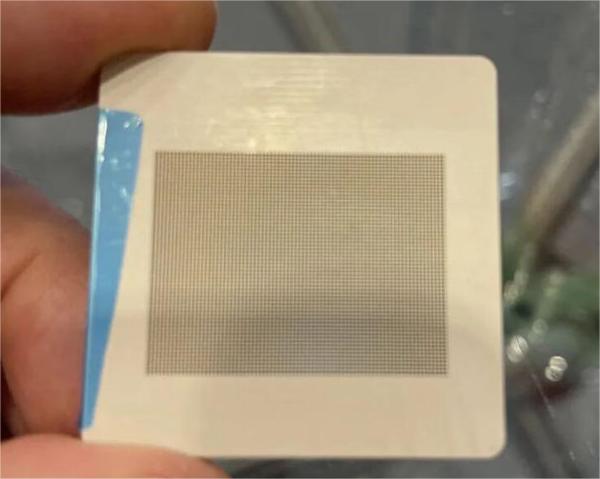

No.12, 30 * 30mm PEEK plate punching 4000 microporous

No.13, PEEK Surgical Robotic Components

Value Proposition:

1, Biocompatible color matching;

2, Excellent dimensional stability.

No.14, PEEK Femoral Condylar Trial Molds

Advantages: 1, high mechanical strength; 2, high toughness; 3, excellent chemical resistance.

II. PI material related products

No.01, PI bushing (powder metallurgy molding method processing)

PI bushing adopts Polyimide (PI) as the main raw material and is manufactured through powder metallurgy molding process, which is a kind of high-performance bushing products.

PI bushing has excellent mechanical properties and chemical stability, and is able to operate stably under harsh working conditions such as high temperature, high pressure and high speed. At the same time, it also has good abrasion resistance, corrosion resistance, insulation and high temperature resistance, and can play an excellent performance in a variety of harsh environments.

No.02, Continuous CF/PI composite plate

Continuous CF/PI composite panels are mainly prepared by the prepreg method, i.e., continuous carbon fibers are pre-impregnated in polyimide resin, and then prepared through curing and hot pressing processes. It is characterized by high strength, high stiffness, low density, excellent high temperature resistance and corrosion resistance, and is capable of long-term stable operation in harsh environments.

No.03.Thermosetting PI sheet and products

Thermosetting polyimide resin does not have the mobility, easy molding and processing characteristics, and curing process will not have small molecule volatiles released, suitable for the preparation of large size, large thickness, high quality products. The cured material has a very high temperature resistance level, excellent dielectric properties, heat and oxidation stability and mechanical strength.

Third, PSU, PPSU materials related products

No.01, PSU, PPSU biopharmaceutical equipment

Bio-pharmaceutical equipment PSU, PPSU quick couplings, manifolds, thermostatic spools

PSU product features: high strength and transparency, excellent chemical resistance, can withstand conventional sterilization methods.

PPSU product features: low cost lightweight metal replacement, corrosion resistant, no metal contamination, potable water contact certified, easy to assemble, saves installation time.

No.02, PPSU manifolds

PPSU household water distributor, 2-way and 3-way fittings and check valve body

PPSU manifold due to lower thermal conductivity than the metal manifold, less condensation in the system when making cold water, less heat dissipation in the system when making heat, and has the advantages of corrosion resistance, cost-effective, long service life and not easy to lose, etc., so many domestic and foreign projects are using plastic manifolds as water distribution and control.

No.03, PPSU tibial spacer test mold piece

Advantages: 1, high toughness 2, colorable 3, excellent chemical resistance

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

PEEK ball is a special type of ball made of polyether ether ketone (PEEK), which has excellent chemical stability, abrasion resistance, and high temperature resistance.PEEK ball is widely used in...

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

Email to this supplier

November 17, 2024

November 16, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.