Flame Retardant Properties and Applications of FR-4 Materials

I. Flame Retardant Properties of FR-4 Material

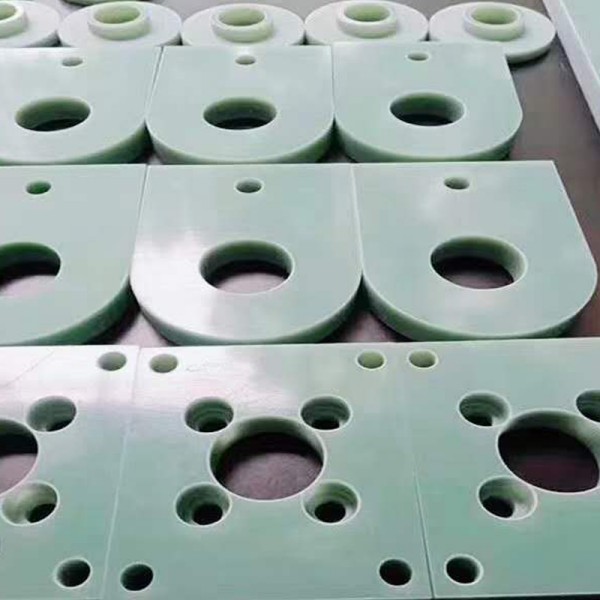

FR-4 material is a kind of epoxy resin glass cloth laminate, which has better insulating properties and high temperature resistance. In the manufacturing process, the combination of glass fiber and epoxy resin makes FR-4 material has high flame retardant properties. In the burning state, FR-4 material can extinguish itself, effectively resisting the flames and reducing the spread of fire. Therefore, FR-4 materials are widely used in electronic equipment, aerospace, automotive industry and other fields to ensure the safety performance of equipment.

Second, the application of FR-4 materials

1. Electronic equipment

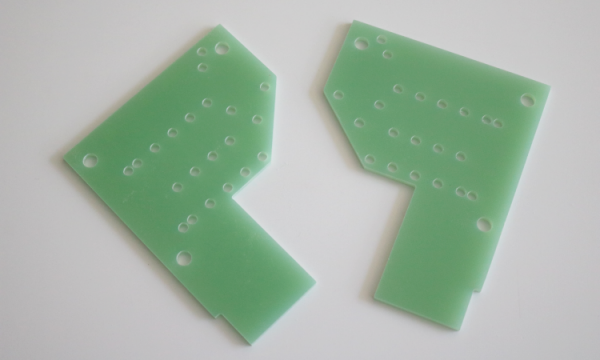

FR-4 materials are widely used in electronic equipment, such as PCB boards, circuit boards, insulation boards, etc.. As FR-4 materials have good insulation properties and high temperature performance, can effectively protect the safety performance of electronic equipment.

2. Aerospace

FR-4 materials are also widely used in the aerospace field, such as aircraft instrument panels, navigation systems, communication systems. Due to the high flame retardant property of FR-4 material, it can effectively resist the attack of fire and protect the safety performance of aircraft.

3. Automotive industry

FR-4 materials are also widely used in the automotive industry, such as automotive circuit boards, engine control systems, in-car entertainment systems. As FR-4 material has better insulation properties and high temperature resistance, it can effectively protect the safety performance of automotive electronic equipment.

Third, precautions

Although FR-4 materials have flame-retardant properties, relevant safety regulations and operating procedures should still be observed when handling such materials in order to prevent fire and other safety accidents. In addition, the fire rating of FR-4 materials depends on their composition and manufacturing process, and should be selected and applied on a case-by-case basis.

In conclusion, FR-4 materials have good flame retardant and insulating properties and are widely used in electronic equipment, aerospace, automotive industry and other fields. In the process of use, attention should be paid to safety regulations and operating procedures to ensure the safety performance of the equipment.

Improving Railway Safety: A Study of Flame Retardant Properties of FR4 Epoxy Sheet

FR4 epoxy board has become a key material for improving rail transportation safety with its flame retardant, electrical insulation and mechanical strength properties, and is widely used in the interior decoration and structural design of rail transportation vehicles.

The safety of rail transit systems is a primary consideration in design and operation. Among many materials, FR4 epoxy sheet is a key material for improving the safety of rail transportation due to its excellent flame retardant properties.

The flame retardant properties of FR4 epoxy sheet are mainly due to its chemical structure and additives. The material burns slowly or self-extinguishes when exposed to flame, effectively slowing the spread of fire and providing valuable time for emergency evacuation and fire response. This is particularly important in enclosed or semi-enclosed rail vehicles, where the risk of fire is higher.

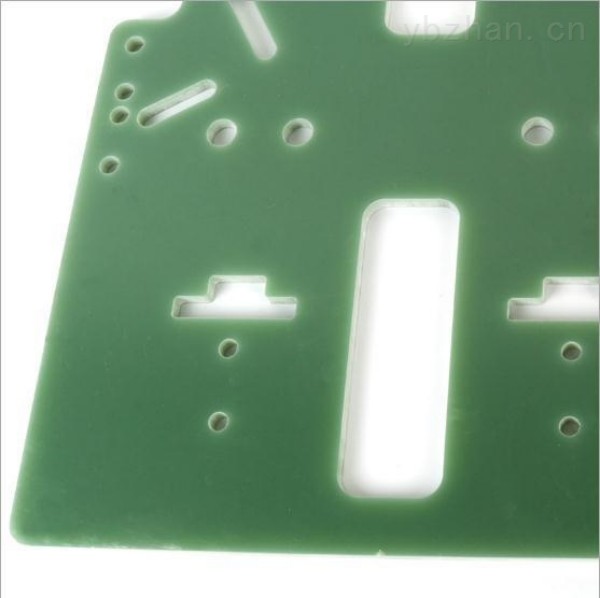

In addition to its flame retardant properties, FR4 epoxy sheet has good electrical insulation properties and mechanical strength. In the electrical system of rail transit, FR4 panels can effectively isolate voltages to protect passengers and equipment. At the same time, its mechanical strength ensures the reliability of application under vehicle vibration and other mechanical loads.

FR4 epoxy panels are also increasingly used in the interior decoration and structural design of rail transit vehicles. From floors to ceilings, from partitions to decorative panels, FR4 panels provide not only an aesthetic appearance, but more importantly, the necessary safety protection.

To summarize, FR4 epoxy board's flame retardant properties, electrical insulation properties and mechanical strength make it an ideal material for improving safety in the rail transportation industry. With the continuous development of rail transportation technology, the application of FR4 epoxy sheet will be even more extensive.