FR4, full name FR-4 epoxy fiberglass sheet, is a high-performance composite material. The following will be a detailed introduction from the definition of FR4, characteristics, applications, and the selection of processing tools.

First, FR4 material introduction

FR4, that is, FR-4 epoxy glass fiber board, is a composite material made of epoxy resin and glass fiber cloth. FR4 is the substrate used in PCB, is a category of sheet material. The “FR” stands for Flame Resistant, and the “4” indicates the performance grade. It has excellent electrical insulation properties, flatness and mechanical strength, as well as good heat and moisture resistance. Therefore, FR4 has been widely used in the electronic field, such as for the production of PCB test fixtures, electrical equipment insulation spacer, transformer insulation board.

Second, the characteristics of FR4 material

1. Stable electrical insulation performance: FR4 material has a high resistivity, can effectively prevent current leakage, to ensure the safe operation of electronic equipment.

2. good flatness: FR4 material has a flat surface, which is conducive to the precise installation and stable operation of electronic components.

3. High mechanical strength: FR4 material has high mechanical strength and can withstand certain external forces and impacts.

4. Good heat and moisture resistance: FR4 materials can maintain stable performance in high temperature and high humidity environment, suitable for a variety of harsh working environment.

Third, the application of FR4 materials

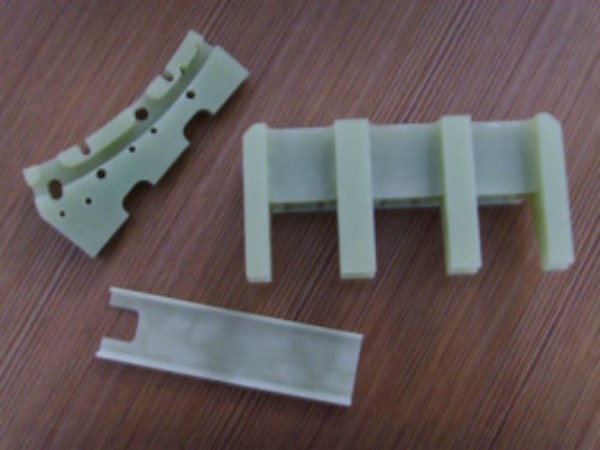

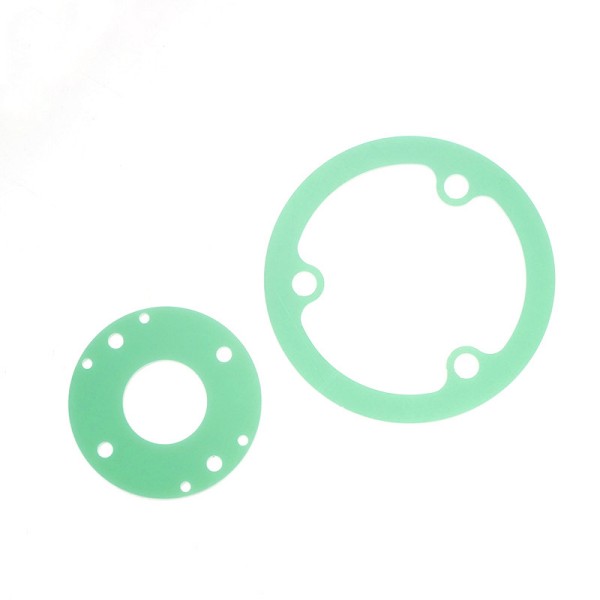

Due to the excellent performance of FR4 material, it has a wide range of applications in the electronic field. For example, it can be used as PCB test fixtures, electrical equipment insulation spacer, transformer insulation board, motor insulation parts. In addition, FR4 material can also be used to make precision vernier gears, precision test plates and other high-precision parts.

Fourth, FR4 processing tool selection

When processing FR4 materials, it is crucial to choose the right tool. Common processing methods include drilling, cutting and milling. For drilling, the general use of drills and drilling machines for processing; cutting can use special cutting tools; and milling requires the selection of suitable milling cutters. These tools need to be characterized by high hardness, high wear resistance and high precision to ensure processing quality and efficiency.

For the processing of FR4 material, it is recommended to use carbide tools or high-speed steel tools. These tools have high hardness and wear resistance and can effectively machine FR4 materials. At the same time, according to the specific processing needs and process requirements, you can also choose different shapes and sizes of tools to meet the actual needs.

V. Summary

As a high-performance epoxy glass fiber composite material, FR4 has a wide range of application prospects in the field of electronics. Understanding its material properties, application areas and the selection of processing tools is crucial to ensure the quality and efficiency of processing.