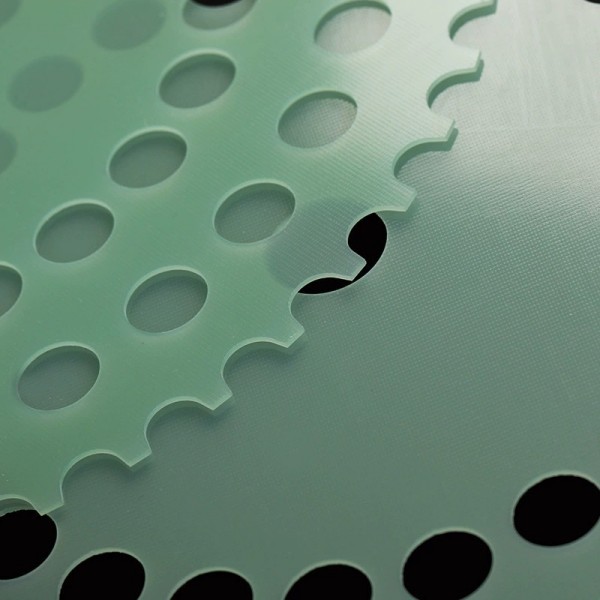

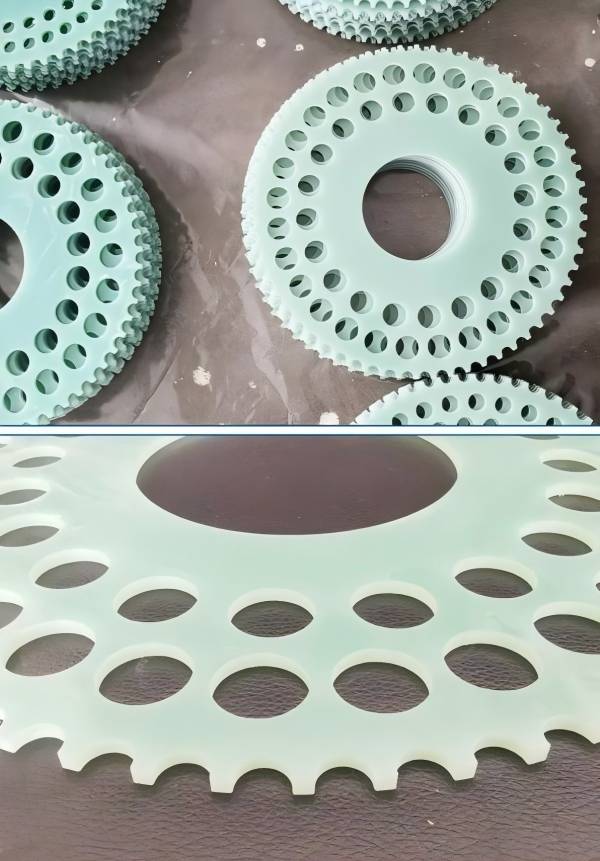

FR4-Glass Fiberboard Star Wheel: Wear-resistant, moisture-resistant, milling, drilling and milling with CNC machining centers

The material of the stargazer wheel includes several kinds of blue steel, stainless steel and epoxy plate. One of the FR4-glass fiberboard is also a kind of insulating board, also called “fiberglass board” and “epoxy resin board”. FR4-glass fiberboard touring wheel with high temperature resistance (180 ~ 200 ℃), moisture resistance, good mechanical properties and dielectric properties, etc. Advantages, common colors are white, white, white, white, white, white, white, blue, white, white, white, white. Advantages, common colors are white, yellow, black, aqua green, FR4 - fiberglass plate planetary wheel is also called “polishing jig”, “polishing pad”, is a kind of polishing process for lenses, silicon wafers, hard disk, glass and other flat polishing fixtures.

FR4-glass fiberboard touring wheel using the raw material epoxy resin characteristics of the advantages:

1, followed by good strength: epoxy resin and amine reaction, the structure produces hydroxyl, good adhesion to other materials.

2, very good mechanical properties: epoxy resin itself has a very good cohesion, mechanical strength is better than general resin.

3, good processing performance: hardening does not produce volatile substances, suitable for different processing conditions.

4、Low hardening shrinkage: shrinkage rate of 1~2%, the smallest among thermosetting plastics.

5, high chemical stability: can tolerate a variety of acids, alkalis, salts and other materials corrosion.

6, good electrical properties: volume resistance of about 1015ohm-cm or more.

7, good heat-resistant properties: cured material heat-resistant 100 ℃, special heat-resistant grade resin can be heat-resistant to more than 200 ℃.

How does the FR4-Fiberglass Sheet Traveler Wheel work?

Mechanical and chemical reaction methods are used to treat the object, making the original rough surface smooth. When our FR4-Glass Fiberglass Plate Crossover Wheel is running at high speed, the surface of the product to be polished produces rolling, micro cutting force, so that the bumps will slowly become flat, become very smooth.

FR4-glass fiberboard traveler wheel production process development and change?

1, the early FR4-glass fiberboard traveler wheel is molded method to produce, because there is no demand for polished workpiece, so the choice of stamping production.

However, this method of production of the planetary wheel there is a rough texture, scrap rate of high determination.