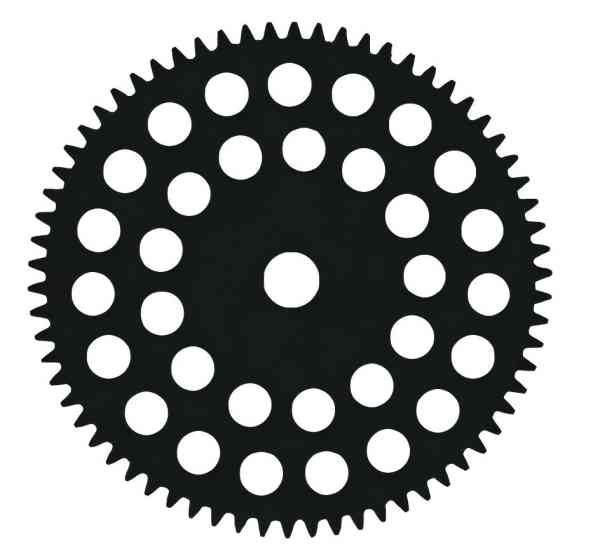

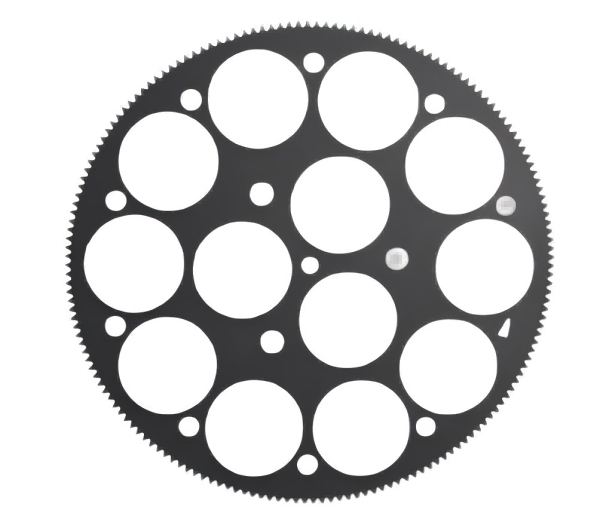

Star wheel is used in glass, lenses, silicon wafers, hard disk and other flat polishing process fixture, also known as polishing fixture, polishing pads, etc.; polishing process development for many years, has been very mature, in recent years, cell phones, tablet computers and other mass electronic products popularized a lot of rapid development of the touch screen, the development of the lens polished by leaps and bounds, the raw material of the wheel by the initial blue steel sheet into the FR-4 fiberglass plate.

At present, the main material of the planetary wheel is FR-4 glass fiber plate, a combination of various characteristics, glass fiber plate is currently the most suitable material for manufacturing planetary wheels on the market, such as: wear-resistant, easy to process molding, processing procedures are simple, does not hurt the polished workpiece, etc., however, the glass fiber plate is mostly for the electronic insulating materials, the wear-resistant parameter for the plate is not high, so compared to the metal sheet, the abrasion resistance of the fiberglass is insufficient, Wei-Bang is here! Weibang has carried out professional exploration and improved the production formula of epoxy resin board

The manufacturing process of the stargazer wheel is very delicate, the polishing of the lens or silicon, gemstone is a very fine process, so the finished product of the stargazer wheel is also very fine, of course, even today, there are still a lot of glass factories use stamping to manufacture the stargazer wheel, the reason is simply because the production cost of this way is very low, and the polishing of the workpiece is also not required, so they will choose stamping! At present, the majority of the tourbillon wheels are now processed by means of computerized gongs, and the great advantage of this method is that the finished product has a very high machining precision, which can be controlled within 0.02mm, and the cut surface is very smooth and clean, and there won't be any burrs, and even the traces of machining can't be seen.

The durability of the Epoxy Plate Star Cruiser Wheel is due to the high quality epoxy resin material used, which not only provides excellent abrasion resistance, but also stays sharp over a long period of time, reducing the need for frequent replacements due to wear and tear. This high durability significantly reduces maintenance costs and material consumption in long-term operation.

In addition, the uniform wear characteristics of the epoxy plate tourbillon wheels ensure consistency in the grinding process, avoiding product quality fluctuations due to uneven grinding effort. This consistency is critical to maintaining a high standard of product quality, especially in applications that require tight tolerance control.

The thickness consistency and anti-warping properties of the epoxy plate traveler wheels during the injection molding and grinding process help reduce runout and ensure continuity and stability in the grinding process. This not only improves productivity, but also reduces cost losses due to production interruptions.

To summarize, the HONY Plastic epoxy plate tourbillon wheel provides an effective solution in precision grinding with its high durability, consistent wear characteristics and warpage resistance. It not only improves productivity, but also helps reduce long-term costs and meets the demanding requirements of the precision machining.