The machining of bakelite panels usually includes steps such as cutting, drilling, milling, and sanding. The following are some common processing methods and steps:

1. Cutting :

- Tools : Bakelite boards can be cut with electric saws, hand saws or laser cutters.

- Methods : According to the design drawings or requirements, cut the bakelite boards into the required size and shape. Chainsaw is suitable to handle large area cutting, while laser cutter is suitable for complex shapes and high precision cutting.

2. Drilling :

- Tool : Drill holes using an electric drill or drill press.

- Method : Drill holes in Bakelite boards as needed, usually for mounting screws or other connectors. When drilling holes, choose the appropriate drill bit to ensure smooth and accurate holes.

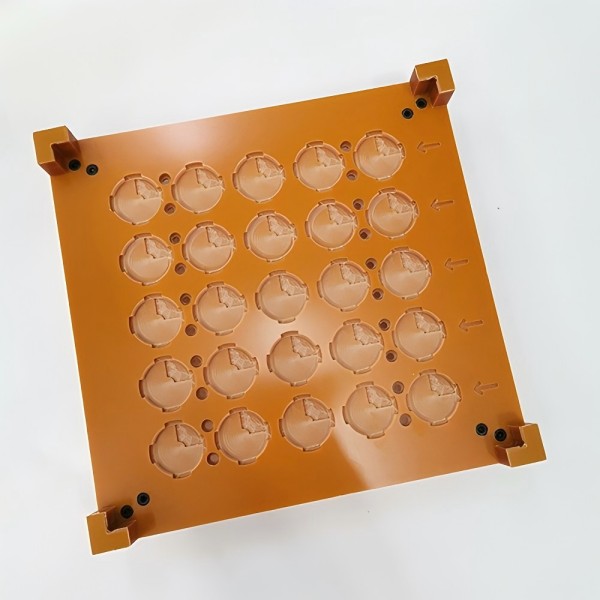

3. Milling :

- Tool : Milling machine or CNC milling machine.

- Methods : Milling is used to process the edges of Bakelite boards or to make grooves and notches. Complex shapes and sizes can be realized by adjusting the depth and position of the milling cutter.

4. Sanding:

- Tool: Sanding with sandpaper or a sander.

- Method: Sanding removes burrs from cuts and drilled holes and ensures a smooth surface. Rough and fine sanding can be done with different grits of sandpaper to achieve the desired surface finish.

5. Thermoforming (optional)

- Tool : Hot air gun or heating oven.

- Method : Bakelite is heated to make it soft for bending or molding. The heating temperature and time should be properly controlled to avoid damage to the material.

6. Gluing and bonding (optional):

- Tools : Glue, adhesive.

- Method : If multiple Bakelite sheets need to be glued together, glue suitable for Bakelite can be used for bonding. Make sure that the glue is applied evenly and that sufficient curing time is given after bonding.

7. Surface treatment :

- Tools : Paint spraying equipment, paint.

- Method : To enhance the appearance and durability of bakelite panels, the surface can be painted or coated.

When processing bakelite panels, the following points need to be noted:

- Protection : Dust generated during processing may cause health problems, so wearing a mask and goggles is recommended.

- Maintenance of tools: Ensure that cutting and drilling tools are sharp and in good condition to improve processing accuracy and efficiency.