PVDF Kynar Fittings Pipe

Get Latest Price| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Hongkong |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Hongkong |

Model No.: PVDF Kynar Fittings

| Selling Units | : | Set/Sets |

| Package Type | : | Export package |

The file is encrypted. Please fill in the following information to continue accessing it

PVDF Pipe Fitting is an extremely resilient, long-lasting and capable material. It is resistant to weak and strong acids, oxidizing acids, mixed acids, organic solvents and many more aggressive media. The density of PVDF--twice that of polypropylene--allows it to retain strength through much turmoil and abuse, so it is ideal for applications that are prone to vibration or impact. PVDF is remarkably durable inside and out.

We offer natural Kynar® PVDF fittings for use with ultra-pure water, deionized/distilled and demineralized water systems, clean chemical processes, pharmaceutical operations, and food processing.

Flame-Retardant PVDF Pipe Flanges for Chemicals

For Use With: Chlorine, Salt Water, Solvents

Temperature Range: 40° to 280° F

Specifications Met: ASTM D3222, UL 94 V-0

Pipe Nipples and Pipe: Use Schedule 80 PVDF Plastic

Fittings: Use Schedule 80 PVDF Plastic

Flanges meet UL 94 V-0 for flame retardance to delay the spread of flames to valuable equipment. They are made of PVDF (polyvinylidene fluoride), which is comparable to Kynar, and has the chemical resistance to stand up to solvents and other harsh substances. Also known as Pressure Class 150 flanges, they have thick, strong walls for heavy duty chemical processing applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. When connecting to pipe, apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the flange, then wrench-tighten one to two turns. Flanges meet ASTM D3222 specifications and testing requirements for material quality.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas

HONY plastics know how critical liquid transport can be so we carry the finest PVDF pipe and fittings available, sure to meet the requirements of your application. If you absolutely cannot have extractables, fungi, leachants or other contaminants in your fluid, and you want your pipes to be durable and long-lasting, PVDF pipe and fittings are the right choice for you.

HONY plastics PVDF piping systems are available in a range of configurations and sizes, both imperial and metric, from 3/8" to over 10" and in a variety of joining methods including socket fusion, butt fusion and bead and crevice free (BCF) fusion. Our threaded PVDF fitting configurations, suitable for lower pressure systems, include tees, elbows, reducer bushings, and more, and come in red and natural colors.

| ITEM | DATA |

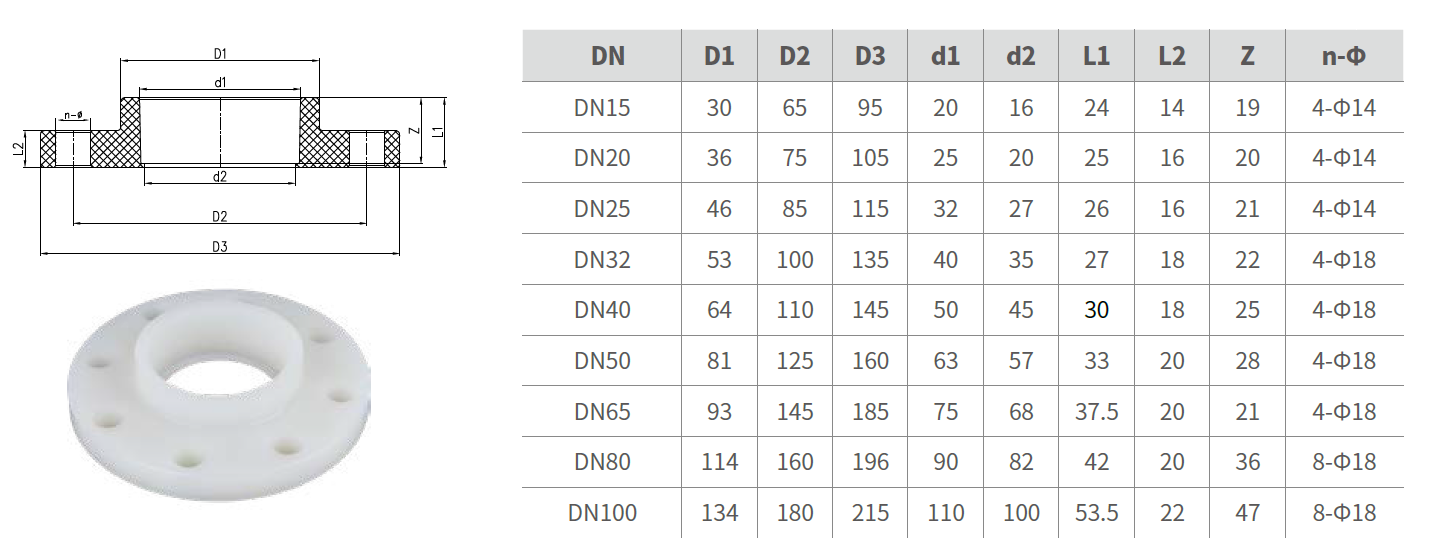

| Flange type | Socket weld flange |

| Flange material | pvdf |

| Flange Size | 1/2' to 6' |

| Flange standard | ANSI, DIN, JIS,GB |

| Working pressure | PN10 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.