Iglidur® G sleeve bearing

Get Latest Price| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Model No.: Iglidur® G sleeve bearing

Brand: iglidur

| Selling Units | : | Piece/Pieces |

| Package Type | : | Export package |

| Download | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

iglidur® G is the most widely used of the iglidur® materials because of its excellent frictional, mechanical, physical and thermal properties in all technical aspects. Sliding bearings made of iglidur® G can be used in a wide range of different industries, and the material has a very wide range of applications. Typical applications include medium to high loads. Typical applications include medium to high loads, medium surface speeds, medium operating temperatures, and media.

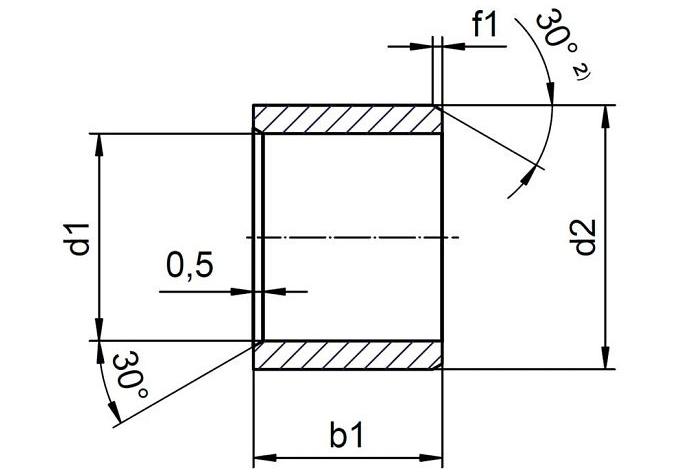

iglidur® G, sleeve bearing, mm

iglidur® G | general purpose bearings

More than 650 sizes always in stock

Very resistant to wear

Resistant to dust and dirt

Highly cost-effective

Self-lubricating and maintenance-free

Applicable occasions:

Economical all-around bearing

Low to medium surface speeds

Bearings need to run on different shaft materials

Oscillating and rotary motion

Not suitable for occasions:

When drilling holes in the bearing wall is required, iglidur® M250 is recommended.

iglidur® W300 is recommended when maximum wear resistance is required.

iglidur® X is recommended when resistance to common chemicals is required.

If the temperature is continuously above +130 °C, we recommend iglidur® H, iglidur® X, iglidur® H370.

For underwater use, iglidur® H370 is recommended.

Tolerances and inspection

In general, the variation of tolerances depends on the thickness of the wall; the thicker the wall of the bearing, the greater the tolerance. iglidur® G standard plain bearings are recommended for shafts with a minimum tolerance of h9, and the bearing bore is automatically adjusted to E10 when the bearing is pressed into a base machined to tolerance H7.

For any material, the water absorption and coefficient of thermal expansion are also important considerations in the design of tolerances. The lower the water absorption and coefficient of thermal expansion, the less the dimensions are affected by the medium and the temperature, and the smaller the tolerances can be designed.

Assembly

iglidur® bearings are press-fit bearings. The shaft can only rotate ideally if they are press-fitted into the base bore with the recommended tolerances. The outer diameter of the plain bearings must be at most 2% larger than the inner diameter of the base bore before press-fitting, so that reasonable interference can be achieved and axial or radial play can be prevented.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.