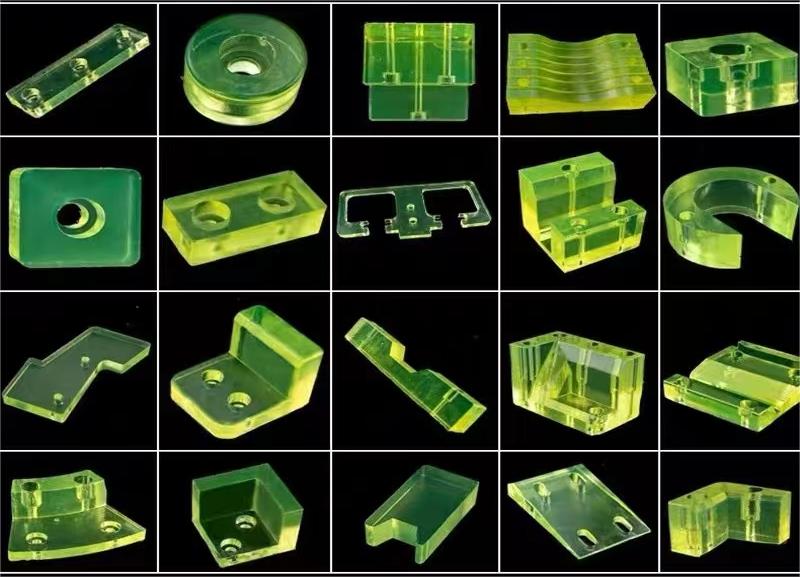

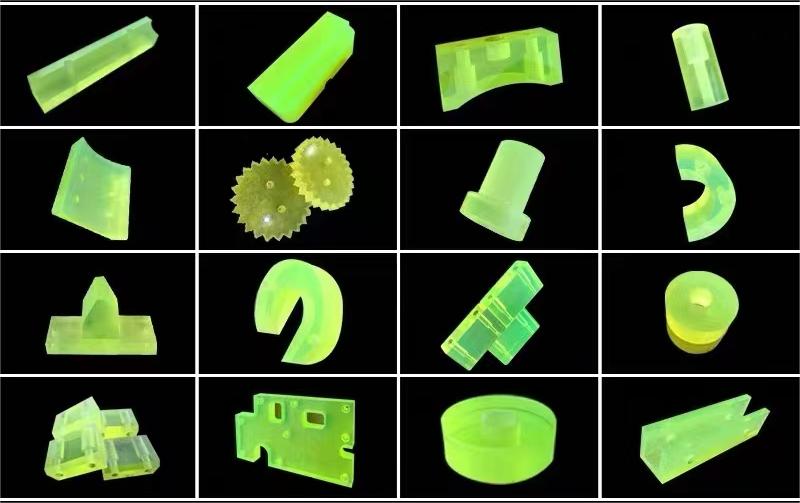

POLYURETHANE MACHINED PARTS PU parts

Get Latest Price| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,DDU,CFR |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,HONGKONG,GUANGZHOU |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,DDU,CFR |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,HONGKONG,GUANGZHOU |

Model No.: HONY-PU

Brand: HONY

| Selling Units | : | Piece/Pieces |

| Package Type | : | Export package |

The file is encrypted. Please fill in the following information to continue accessing it

HONY®PU Polyurethane, abbreviated as PU, is a polymer material. Polyurethane is an emerging organic polymer material, which is known as the “fifth largest plastic” and is widely used in many fields of the national economy due to its excellent performance. Product applications include light industry, chemical, electronics, textile, medical, construction, building materials, automotive, defense, aerospace, aviation and so on.

Hony plastic produce a range of Machine Polyurethane Parts including Skirting Rubbers, various ranges of Scrapers, refurbishment of Polyurethane Wheels and Rollers, PU Seal & Anti Vibration Mountings.

Hony Plastic are well suited for polyurethane machining processes — machining , cutting , contouring , milling , turning ,facing , parting , knifing , grinding , drilling .

There are many similarities between machining polyurethane and machining metals – but there are also some important differences. Take a minute to familiarize yourself with this information to understand these differences.

PU plastic has a machining cost factor of 0.7 when compared to steel 12L14.

CNC MACHINING ABS PLASTIC PARTS of PU Characteries

1. Wide range of hardness. It still has the elongation and resilience of rubber under high hardness. The hardness range of the polyurethane board is Shore A10-D80.

2. High intensity. Under rubber hardness, their tear strength, tear strength and load-bearing capacity are much higher than general rubber. Under high hardness, its impact strength and bending strength are much higher than plastic.

3. Wear resistance. Its wear resistance is very outstanding, generally in the range of 0.01-0.10(cm3)/1.61km, which is about 3-5 times that of rubber.

4. Oil resistance. Polyurethane board is a kind of strong polar polymer compound, it has little affinity with non-polar mineral oil, and it is hardly corroded in fuel oil and machine oil.

5. Good resistance to oxygen and ozone.

6. Excellent vibration absorption performance, which can be used for vibration reduction and buffering. In the mold manufacturing industry, it replaces rubber and springs.

7. It has good low temperature performance.

8. Radiation resistance. Polyurethane has good resistance to high-energy rays and still has satisfactory performance under 10-10 Ge radiation doses.

9. It has good mechanical processing performance. (Car, milling, grinding, drilling all possible)

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.