Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PCTFE is a polymer with a linear backbone of repeating units initiated by the radical-initiated polymerization of vinyl trifluoride.

PCTFE is a crystalline polymer with a melting point of 217°C and a density of 2.13 g/cm3. PCTFE is inert to most active chemicals at room temperature, while it can be solubilized by a few solvents and swollen by some solvents above 212°C. PCTFE has excellent gas barrier capability.

PCTFE has excellent gas barrier ability, and the water vapor permeability of its film products is the lowest among all transparent plastic films.The electrical properties of PCTFE are similar to those of other perfluoropolymers, but the dielectric constant and loss factor are slightly higher, especially at high frequencies.

Instructions for use:

Polytrifluoroethylene has excellent cold resistance, high strength and hardness, good dimensional stability and no tendency to cold flow. Thermal conductivity of 0.25W/(m.c), coefficient of linear expansion of (9.5-19.6)*10^-5/°C, tensile strength of 19-20MPa, modulus of elasticity of 1300MPa, compressive strength of 50-70MPa, bending strength of 70MPa. It is resistant to inorganic acids at a high temperature, salt-soluble strong oxidizers at a low temperature, and also resistant to most organic at room temperature. Medium, valve use pressure below 25MPa.

The main properties of PCTFE:

1. In terms of mechanical properties, the room temperature mechanical properties of PCTFE is better than PTFE, its compression strength is large, the cold flow is small, the compression resilience is also relatively large, with good elastic recovery.

2. PCTFE's low-temperature resistance is particularly outstanding, in liquid nitrogen, liquid oxygen and liquefied natural gas without brittle cracking, no creep, and under certain conditions can be used near absolute zero (-273 ℃).

3. High fluorine content makes PCTFE resistant to almost all chemicals and oxidizers. It can be impregnated in acid, alkali or oxidizer for a long time without any change, and it can be corroded only at high temperature by dissolved alkali metals, elemental fluorine and chlorine trifluoride.

What makes PCTFE unique

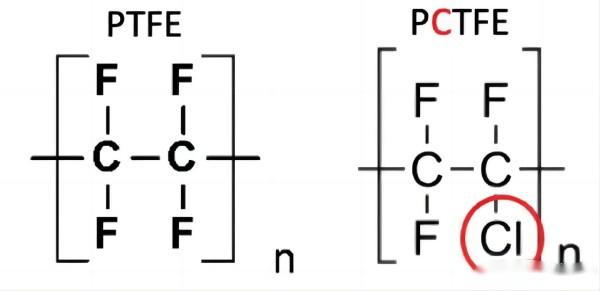

Comparing PCTFE (polychlorotrifluoroethylene) with PTFE (polytetrafluoroethylene - the workhorse of the fluoropolymer family) leads to a practical conclusion. At first glance, the molecular formulas are identical except that one fluorine atom on the PTFE molecule is converted to a chlorine atom.

However, this may seem like a small change; the addition of chlorine atoms leads to a huge difference in the final properties of the material.

Let's take a look at the effect of chlorine atoms on material properties:

Chemical resistance - PTFE is a fully fluorinated molecule and is therefore virtually impervious to chemical attack, even in strong acids. pCTFE is partially fluorinated, but the polymer contains three of the four fluorine atoms, and therefore has good chemical resistance, but does not meet the high standards of PTFE, especially in aromatic and halogenated solvents.

Mechanical Properties - PTFE is often the product of choice when high voltages, extreme chemical resistance and high thermal performance are required. However, if high dimensional stability over a wide temperature range is required, or if high mechanical strength is needed, PTFE may not be suitable for this application. pctfe has approximately twice the tensile strength of ptfe, with a much lower elongation and a tensile modulus that is 2.5 times that of ttfe.

Thermal Properties - The addition of chlorine atoms reduces the melting point of PCTFE to 410°F compared to the melting point of PTFE of 621°F. This needs to be considered in your application.

In summary, the dimensional stability of PCTFE falls between that of advanced specialty polymers such as PEEK, PPS and PTFE, but still offers excellent performance. In addition, PCTFE has very low outgassing values and the low flammability of fluoropolymers.

November 04, 2024

November 03, 2024

August 27, 2021

August 26, 2021

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

What are the common machining methods used for PTFE parts processing? PTFE parts processing commonly used machining methods are: Molding Molding is suitable for processing simple parts directly once...

Email to this supplier

November 04, 2024

November 03, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.