Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

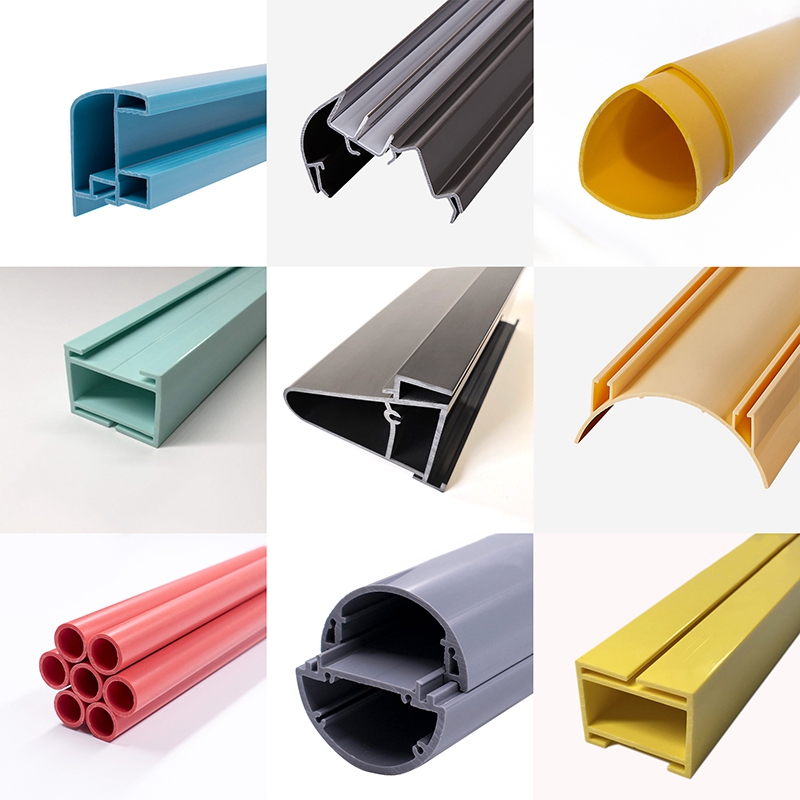

HONYPRO®PVC ABS PC PE PP PMMA Extrusion plastic profile

The extrusion plastic profile is an extruded plastic product with a non-circular cross-section called a plastic profiled material. Except for round, square, and plate profiles, such as corrugated, grooved, T-shaped and other arbitrary shapes. Plastic profile is a profile with plastic as the main material, which is widely used in construction and decoration, daily necessities, automotive profiles and other industries.

There are two types of profiles: one is all-plastic profile, and the other is a composite profile made of plastic materials and non-plastic materials. According to the degree of softness and hardness of the profile, it can be divided into soft profile and hard profile. According to the classification of plastics, it can be divided into: PVC profile, ABS profile, PE profile, etc. Most of them are PVC profile. Our company can customize profiles of any plastic material, and can develop raw materials that meet customer performance according to customer needs.

Performance characteristics

The plastic profile has excellent performance such as light weight, corrosion resistance, flame retardant, good load-bearing performance, strong decoration and convenient installation.

Wide range of applications

Application and construction, electrical appliances, furniture, transportation, civil engineering, water conservancy, daily necessities, etc. Soft profiles are mainly used as gaskets and seals, and hard profiles are mainly used as structural materials.

Product category

Profiles can be divided into the following categories according to the nature of the material:

1) Soft profiled materials. Such as sealing strips, hoses, rubber strips, etc. The product can be bent at will;

2) Hard profiled materials. Such as window profiles, industrial assembly parts, etc. to give similar profiles;

3) Co-extrusion of soft and hard profiles. Can maintain the hardness of the hard profile and have the performance of the soft profile;

4) Two-color co-extrusion profiled material. Such as handrail profiles, etc., the surface of the profile can be customized in different colors according to customer requirements;

5) Foam profiled materials. Such as garden fences, foamed materials, etc., reduce the weight of the profile and maintain good performance;

6) Other profiled products. According to customer drawings or samples, various profiles can be designed according to customer needs

Performance characteristics

The plastic profile has excellent performance such as light weight, corrosion resistance, flame retardant, good load-bearing performance, strong decoration and convenient installation.

Wide range of applications

Application and construction, electrical appliances, furniture, transportation, civil engineering, water conservancy, daily necessities, etc. Soft profiles are mainly used as gaskets and seals, and hard profiles are mainly used as structural materials.

Performance parameter

1. Expansion temperature: the initial expansion temperature is 199℃, and the main body expansion temperature is 347℃;

2. Expansion multiple: greater than or equal to 10-30 times the thickness of the original expansion body;

3. High temperature resistance: the temperature rises to 980℃ and keeps it for 30 minutes, without burning or ashing;

4. Smoke prevention performance: the fire resistance test is carried out for 72 minutes, there is no obvious smoke leakage at the left, right and upper gaps of the door installation seal, and the smoke prevention performance is greater than 72 minutes;

5. Environmental resistance: the expansion ratio will not change when placed at room temperature and 90 humidity for 120 days.

Product advantages

1. Light weight, heat insulation, heat preservation, moisture proof, flame retardant, acid and alkali resistance, and corrosion resistance.

2. Good stability, dielectric properties, durability, anti-aging, easy welding and bonding.

3. Strong flexural strength and impact toughness, high elongation when broken.

4. It is extremely easy to process and shape through processes such as kneading, mixing, drawing, pelletizing, extrusion or die-casting, which can meet the needs of various profile specifications.

5. The surface is smooth, the color is bright, and it is very decorative, and it has a wide range of decorative applications.

6. The construction process is simple and the installation is more convenient.

7. Low price. It is a very good high-tech alternative product, which can replace aluminum, steel, ABS and other engineering plastics.

Advantage

1. There is a separate granulation workshop, which produces PVC extrusion raw materials by itself, and the quality is easy to control, and the supply is timely, and there will be no quality problems caused by unstable raw materials.

2. There is a separate mold workshop, and the mold masters have many years of experience in mold opening and testing. The mold opening cycle is shortened, the appearance is well grasped, the size is accurate, and it is easy to adjust during the production process.

3. There are more than one hundred high-speed production lines, several high-tech production lines, the workshop technicians are experienced in extrusion, the product quality is well controlled, and the quality inspection is strict.

4. There is a separate metalworking workshop, with professional mechanical engineers, for product processing such as: punching, filming, stickers, transfer printing, and assembly can meet customer standards.

5. HONY plastic has a modern laboratory, which can test all the related physical properties and formula composition of plastics.

6.HONY plastic company has internal and external sales teams and an independent transportation team to escort your goods throughout the process.

Please send inquiry and drawing to sales@honyplastic.com

November 04, 2024

November 03, 2024

August 27, 2021

August 26, 2021

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

What are the common machining methods used for PTFE parts processing? PTFE parts processing commonly used machining methods are: Molding Molding is suitable for processing simple parts directly once...

Email to this supplier

November 04, 2024

November 03, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.